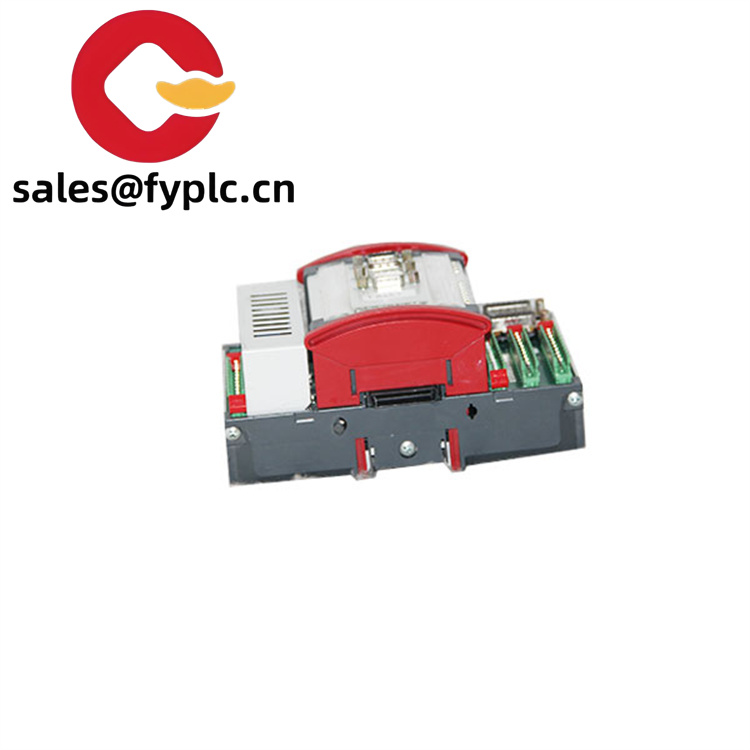

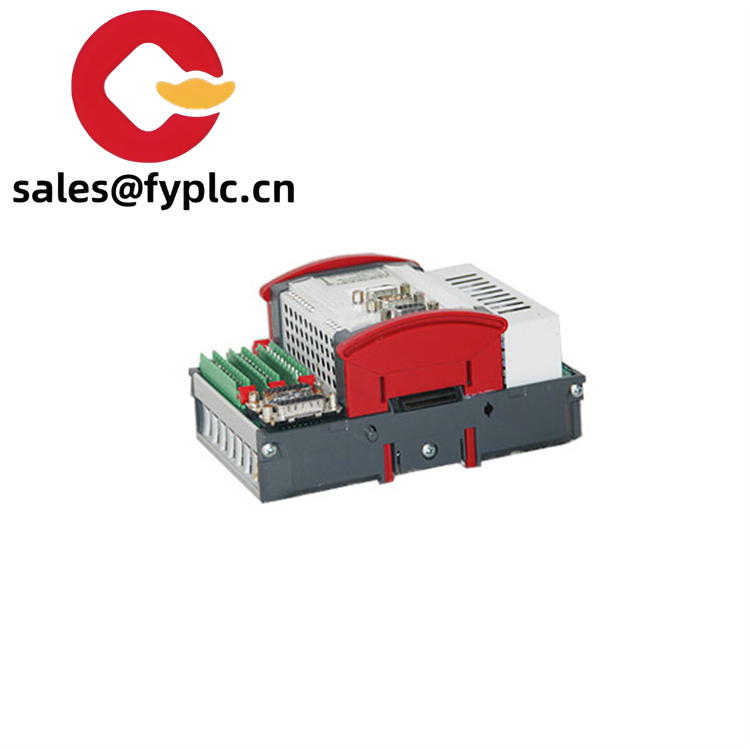

BERGHOF RDC2 PLC Redundancy Module Automation GmbH

Brand model: BERGHOF

Product Name: RDC2

Warranty: 1 year

Size: 85 mm x 55 mm x 30 mm (compact variants)

Weight: 1.2kg

Status: New/Used

Categories: HONEYWELL

Need help?

Email: sales@fyplc.cn

Tel/WhatsApp: +86 173 5088 0093

Description

BERGHOF RDC2 PLC Redundancy Module Automation GmbH

Notably, the RDC2 excels in scenarios demanding synchronized multi-device coordination, such as automated production lines and environmental monitoring systems. Its compact design and wide operating temperature range enable seamless installation in space-constrained cabinets or outdoor enclosures, while compliance with global industrial standards ensures interoperability with third-party sensors and actuators .

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | BERGHOF RDC2 PLC |

| Manufacturer | BERGHOF Automation GmbH |

| Product Type | Modular Industrial Controller / PLC |

| Processor | High-performance ARM® Cortex™-A9 (up to 800 MHz); optional quad-core variants |

| Memory | Up to 2 MB (base model); expandable via µSD card (up to 64 GB) |

| Power Input | 24 V DC (±10%); optional 230 V AC variant |

| Communication Protocols | Ethernet (TCP/IP, EtherCAT, Profinet, Modbus TCP), RS-232/485 (Modbus RTU), CANopen |

| Operating Temperature | -20°C to +60°C (-4°F to 140°F) ; extended range (-40°C to +70°C for rugged variants) |

| Protection Class | IP65 (front panel); IP20 (rear terminals) |

| Dimensions | 85 mm x 55 mm x 30 mm (compact variants) |

| Programming Environment | CODESYS V3 (IEC 61131-3 compliant) |

| Certifications | DIN EN ISO 9001:2015; RoHS compliant (safety certifications like ATEX/IECEx pending model-specific verification) |

Key Features and Benefits

-

Modular Flexibility: The RDC2’s scalable architecture supports up to 10 I/O modules, enabling customization for tasks ranging from simple logic control to complex motion sequencing. Its plug-and-play design reduces downtime during upgrades or repairs .

-

Real-Time Performance: With a processing speed of up to 50 MHz and cycle times as low as 500 µs, the RDC2 handles time-critical operations such as synchronized motor control and high-speed data acquisition—critical for applications like precision manufacturing and robotics .

-

Rugged Reliability: Built to withstand extreme temperatures, humidity (up to 95% non-condensing), and electromagnetic interference, the RDC2 thrives in harsh environments such as industrial plants, outdoor renewable energy installations, and mining facilities .

-

Seamless Connectivity: Equipped with Gigabit Ethernet, serial ports, and optional wireless modules (Wi-Fi/Bluetooth), it integrates with SCADA systems, IoT platforms, and legacy equipment. Support for protocols like OPC UA and MQTT facilitates cloud-based monitoring and predictive maintenance .

-

User-Centric Design: Features like hot-swappable modules, LED status indicators, and a maintenance mode for easy troubleshooting simplify on-site operations. The CODESYS V3 programming environment supports multiple languages (ST, FBD, LD), reducing training time for engineers .

Application Scenarios

- Industrial Automation: Controls conveyor systems, packaging machinery, and assembly lines in automotive and electronics manufacturing, ensuring precise timing and error detection .

- Renewable Energy: Manages solar inverter synchronization and wind turbine pitch control, leveraging fast communication to optimize energy output .

- Environmental Monitoring: Integrates with sensors for temperature, humidity, and gas detection in smart grids and wastewater treatment plants, enabling real-time data-driven decisions .

- Mobile Machinery: Powers control systems for construction equipment and agricultural vehicles, where its rugged design and low power consumption are advantageous .

Related Models

- BERGHOF MC Series: Modular PLCs with enhanced EtherCAT support, ideal for large-scale industrial networks .

- BERGHOF DC Series: PLC-HMI 一体机 with integrated touchscreens, suited for applications requiring local visualization .

- BERGHOF RDC2-E: Enhanced variant with extended communication protocols (e.g., BACnet) for building automation .

Installation and Maintenance

- Mounting: DIN rail or panel mounting with IP65-rated front panels for dust and water resistance in harsh settings .

- Configuration: Initial setup via CODESYS V3 software; IP address management through preconfigured defaults (169.254.255.XX) or maintenance mode for recovery .

- Diagnostics: Built-in self-test functions and LED alerts for power, communication, and fault status. Historical data logging supports root-cause analysis .

- Firmware Updates: Via USB or Ethernet, with backward compatibility ensured through BERGHOF’s software maintenance program .

Be the first to review “BERGHOF RDC2 PLC Redundancy Module Automation GmbH” Cancel reply

Reviews

There are no reviews yet.