Description

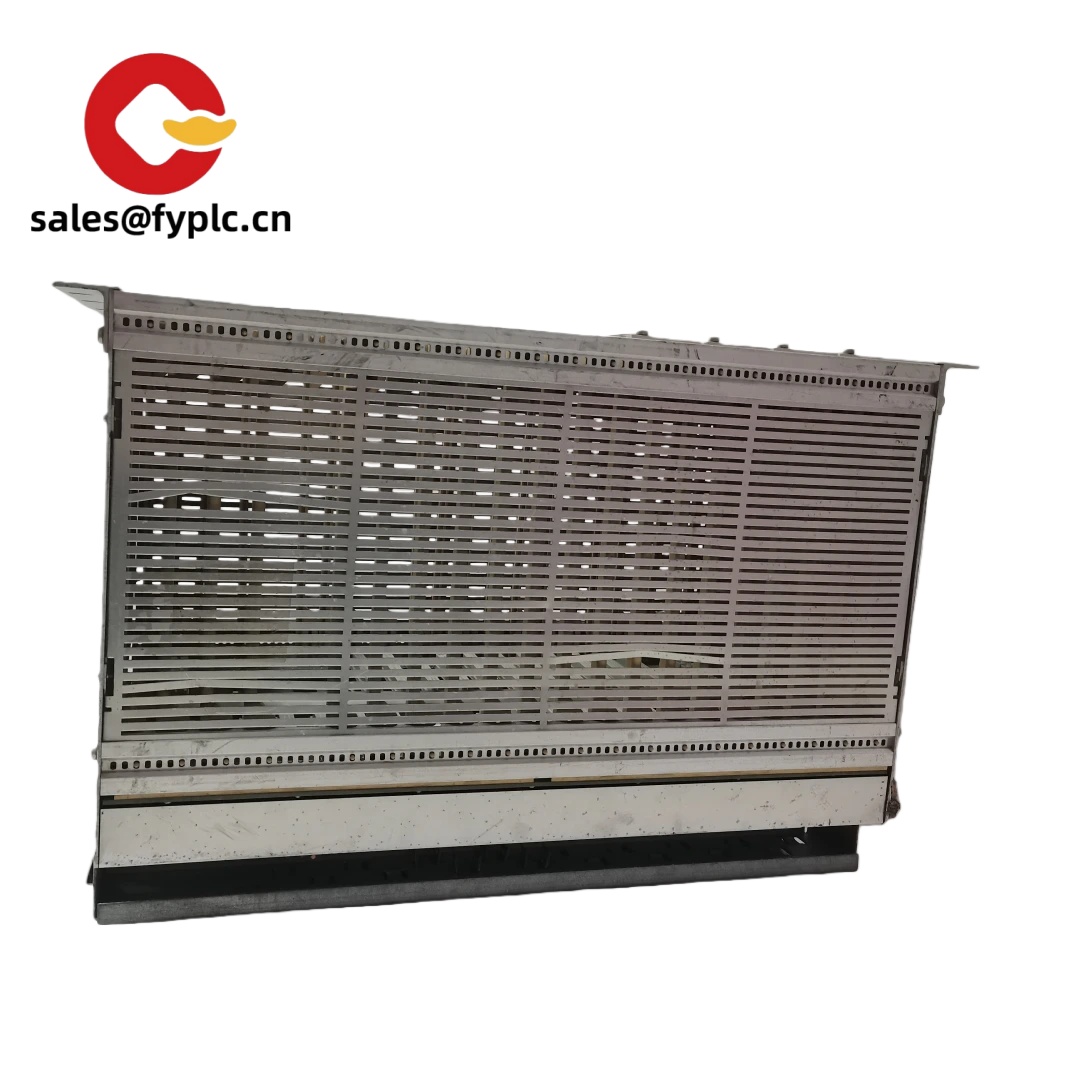

216MB66 HESG324510M1 is a multifunctional industrial automation product launched by ABB, combining the core features of an Input/Output (I/O) module and a Variable Speed AC Drive. It is suitable for data acquisition, equipment control, and speed regulation coordination in industrial scenarios. The following is its complete product information:

Features

1. Multifunctional Integrated Design: Combines the data interaction capabilities of I/O modules with the power control functions of variable frequency drives, allowing direct connection to sensors, actuators, and other field devices. It achieves an integrated “data acquisition – processing – speed control” system, simplifying the system architecture.

2. High Reliability and Safety: Made from high-performance industrial-grade materials with electrical isolation to effectively resist electromagnetic interference, enhancing system anti-interference capability. Built-in multiple protection mechanisms such as overcurrent, overvoltage, and undervoltage ensure the safety of equipment and personnel.

3. Precise Control and High Energy Efficiency: High variable frequency drive precision supports a wide frequency range adjustment from 0Hz to 80Hz, dynamically adjusting output according to load demands to reduce energy consumption. The 96% high-efficiency design further minimizes energy loss, suitable for energy-saving industrial scenarios.

4. Flexible Expansion and Compatibility: Supports various communication protocols and interfaces, seamlessly integrating into different industrial control systems (e.g., PLC, DCS). Compatible with multiple signal types such as analog and digital, meeting the connection requirements of different industrial equipment.

5. Easy Installation and Maintenance: Features a compact modular design with simple interfaces, making installation straightforward. Reserved maintenance channels combined with status indication functions facilitate on-site troubleshooting and routine maintenance, reducing operational costs.

Widely applicable to industrial scenarios that require both data interaction and speed control, with core applications including:

1. Process Industry: Production process control in industries such as chemical, petrochemical, and pharmaceutical, including reactor temperature/pressure regulation, material transport pump speed adjustment, etc.;

2. Manufacturing: Automotive production, machining, and production line automation, such as conveyor belt speed control, machine tool spindle speed regulation, fan/water pump frequency adjustment, etc.;

3. Energy and Infrastructure: Control of auxiliary equipment in power plants, aeration tank fan speed regulation in water treatment plants, frequency control of pumps in heating systems, etc.;

4. Other Scenarios: Production line control in industries such as metallurgy and building materials, as well as various industrial automation systems that require both data acquisition and drive speed regulation.

Reviews

There are no reviews yet.