Description

ABB FC95-22 (HESG440295R2 / HESG448688R22) – Procontrol P14 Control Module for Reliable DCS Operation

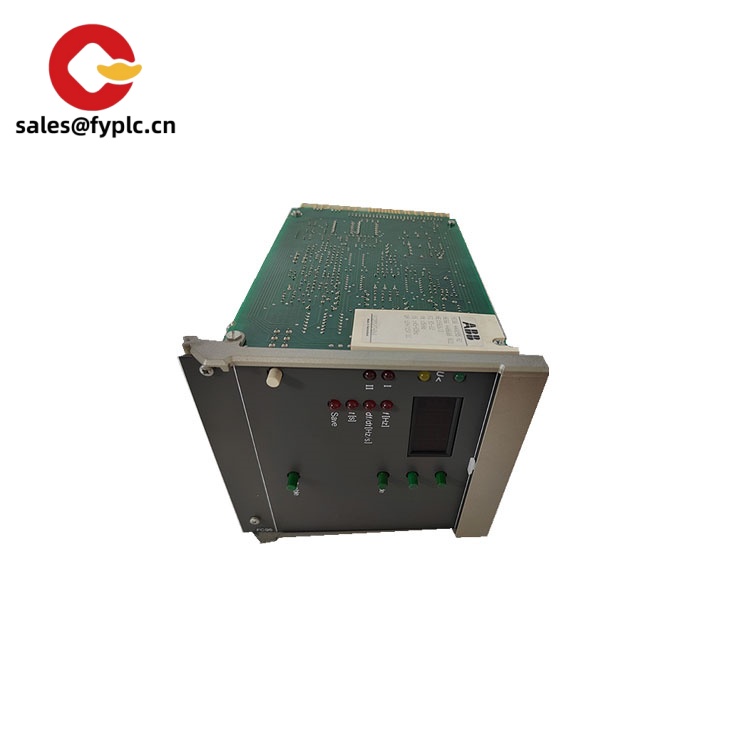

The ABB FC95-22, referenced by board codes HESG440295R2 and HESG448688R22, is a Procontrol P14-series plug-in control module used in legacy ABB DCS installations. It’s typically deployed as a controller/coordination board within the rack to handle sequence logic, interlocking, and deterministic communications over the system backplane. From my experience, teams choose FC95-22 when they need a stable drop-in replacement that preserves existing I/O wiring and control logic while minimizing downtime.

You might notice that the FC95-22 seems to be favored in plants where uptime is non-negotiable—power, petrochemical, and cement lines, for example—because it fits the original Procontrol P14 mechanics and keeps the installed base viable without a full DCS migration.

Order Placement Process and Guarantees

- Warranty: 365 days coverage

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express: FedEx, UPS, DHL

Key Features

- Procontrol P14 compatibility – Designed for P14 racks/backplanes, allowing straightforward swap with minimal re-engineering.

- Deterministic backplane communications – Stable real-time exchange with peer modules and I/O cards for predictable loop and sequence execution.

- Front-panel status & diagnostics – LEDs and basic test points to speed up commissioning and fault tracing in the cabinet.

- Backplane-powered – No separate field power required; the module draws from the system supply, which simplifies wiring.

- Ruggedized for plant environments – Typically qualified for control-room conditions (0–55°C) and continuous operation.

- Lifecycle-friendly – Suits phased modernization strategies where you extend system life while preparing for future migration.

Technical Specifications

| Brand / Model | ABB FC95-22 (HESG440295R2 / HESG448688R22) |

| HS Code | 8538.90 (Parts for electrical control apparatus) |

| Power Requirements | Supplied via Procontrol P14 backplane (no external field supply; typical module consumption < 10 W) |

| Dimensions & Weight | Rack plug-in card; typical 6U Eurocard form factor, approx. 220 × 160 mm; ~0.5 kg |

| Operating Temperature | 0 to +55 °C (control room conditions), 5–95% RH non-condensing |

| Signal I/O Types | Internal system bus I/O via backplane; front-panel status LEDs; no direct field I/O on the module |

| Communication Interfaces | Procontrol P14 backplane bus; service/diagnostic access as per front-panel provisions |

| Installation Method | Plug-in module for P14 rack; front retainers/screws; ESD-safe handling recommended |

Application Fields

This module is typically used in ABB Procontrol P14-based plants where continuity is essential:

- Power generation (boiler/balance-of-plant sequence control, turbine auxiliaries)

- Petrochemical and refining (interlocks, compressor trains, utilities)

- Cement and minerals (kiln, mill, and material handling logic)

- Metals and pulp & paper (drives coordination, process protection schemes)

One thing I appreciate is how it supports “brownfield” strategies—keeping legacy cabinets in service while you plan migrations in stages, which in many cases saves both time and shutdown costs.

Advantages & Value for Procurement

- Drop-in replacement – Keeps the existing P14 infrastructure, wiring, and logic intact.

- Reduced downtime – Fast swap and familiar diagnostics shorten outage windows.

- Lifecycle extension – A practical way to stabilize legacy assets before a major DCS refresh.

- Compatibility assurance – Matched to the Procontrol P14 form factor and backplane signaling.

- Support options – We assist with part validation by serial/board code (HESG440295R2 / HESG448688R22) to avoid mismatches.

A maintenance manager recently shared that swapping to FC95-22 cut their troubleshooting time in half, mostly because the front-panel indications matched their team’s standard operating procedures and saved them a few cabinet door openings during shifts.

Installation & Maintenance

- Cabinet & rack – Install in an ABB Procontrol P14 rack in a dry, ventilated control-room cabinet; maintain clearance for airflow.

- Wiring – No field wiring to the module; ensure the backplane connectors are clean and fully seated.

- ESD & handling – Use ESD wrist straps and antistatic packaging; avoid touching edge contacts.

- Start-up checks – Verify module addressing/jumpers as per site documentation; confirm status LEDs and system heartbeat.

- Routine care – Quarterly dust removal (dry air, low pressure), visual inspection of connectors, and periodic function checks in line with site maintenance plans.

- Spare strategy – Keep at least one qualified spare on site; record module firmware/hardware revisions for consistent behavior across bays.

Quality & Certifications

- Manufacturer quality system: ISO 9001

- Product conformity: CE-marked for industrial environments (typical for ABB control modules)

- UL/CSA: Applicable at system or cabinet level in many installations

- RoHS: Compliance may vary by production year; declaration available on request

- Warranty: 365 days replacement/repair support

Related/Supporting Components

To streamline commissioning, many teams pair the FC95-22 with compatible ABB Procontrol P14 backplane racks, system power supplies, and I/O cards (DI/DO/AI/AO) from the same P14 family. We can help verify cross-compatibility by part number and HESG code before shipment.

Reviews

There are no reviews yet.