Description

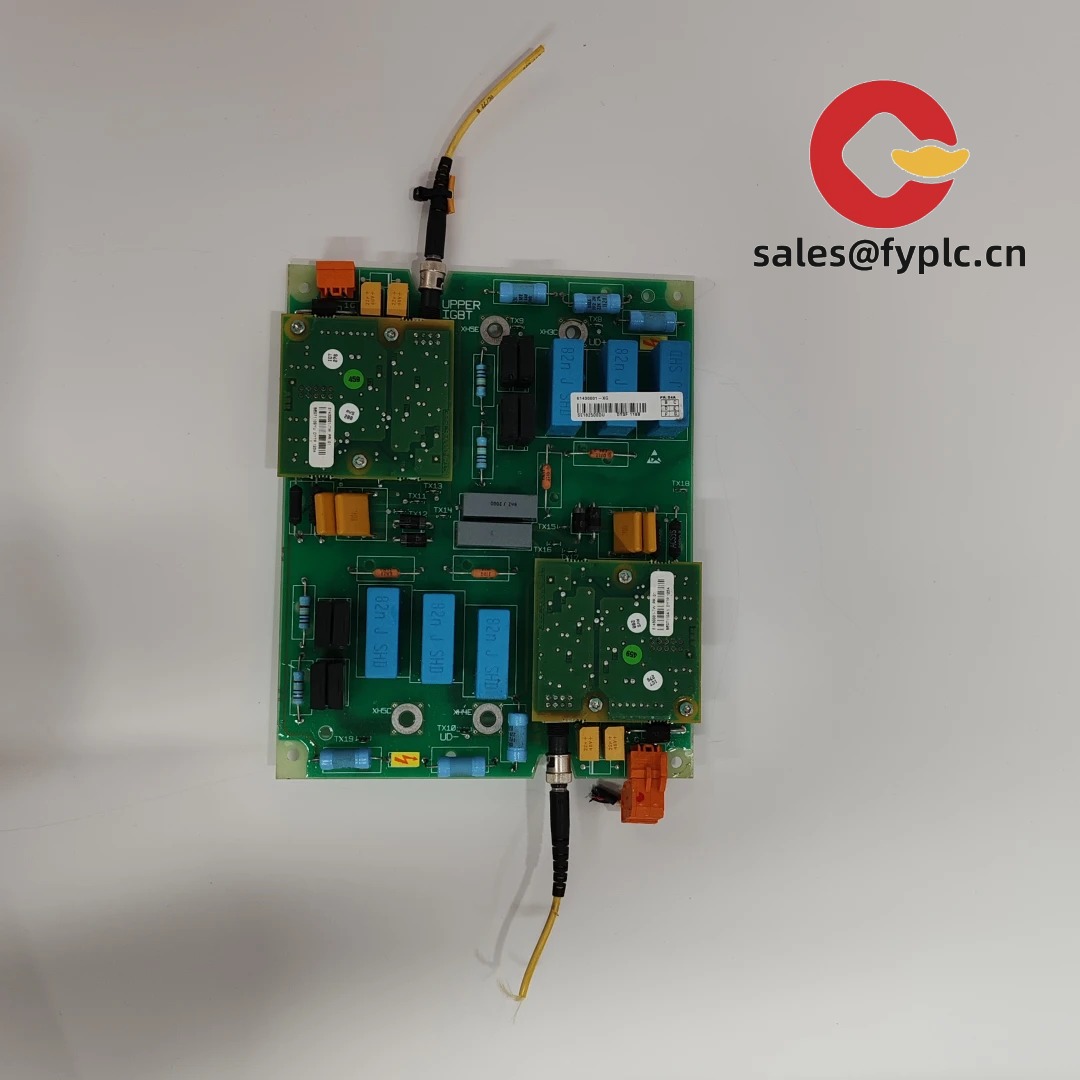

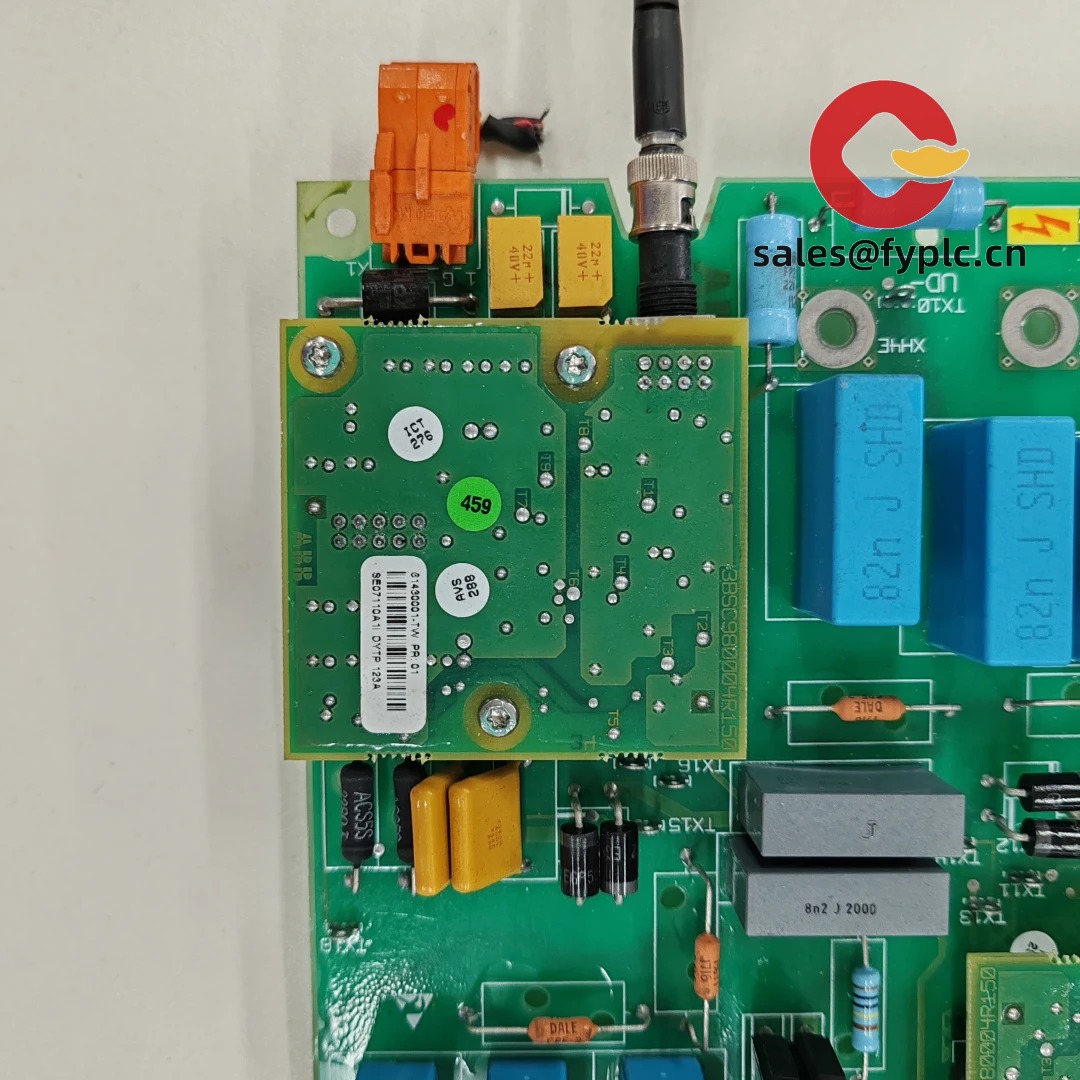

ABB DYTP123A (61430001-TW) Touch Panel – Replacement HMI front module for ABB operator terminals

The ABB DYTP123A, part number 61430001-TW, is a factory-grade touch panel assembly used on ABB operator terminals in DCS/PLC environments. From my experience, it’s the piece you need when the screen still displays but the touch response is erratic, glass is cracked, or calibration drifts. It’s designed as a drop-in front module so maintenance teams can restore usability without replacing the entire HMI unit—typically saving both downtime and budget.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full balance prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Drop-in replacement – Fits the original DYTP123A mounting and connector scheme, keeping retrofit time short.

- Industrial-grade touch – The panel is built for 24/7 HMI use; in many cases it withstands glove operation and frequent presses.

- Stable usability – Helps recover lost touch accuracy and responsiveness without altering the host CPU or application.

- Service-friendly – Front-panel replacement typically avoids rewiring, so technicians can swap it during a planned stop.

- Compatibility-first – Calibrates with the standard ABB HMI routine; no special tools required in typical cases.

- Cost control – Replacing the touch assembly instead of the complete HMI often cuts parts spend and shortens downtime.

Technical Specifications

| Brand / Model | ABB DYTP123A (Part No. 61430001-TW) |

| HS Code | 8537.10 (commonly used for HMI/industrial control panels; final classification may vary by country) |

| Power Requirements | 24 VDC nominal (typical HMI supply environment) |

| Operating Temperature | 0 to +50 °C (panel-mounted; consistent with standard HMI practice) |

| Signal Input/Output Types | Touch input to host HMI controller (typ. analog resistive); display interface as per original ABB design |

| Communication Interfaces | Internal FFC/FPC connectors to the HMI mainboard; no direct field bus on the panel itself |

| Installation Method | Front-panel mounting with gasket and retaining clips; ESD-safe handling recommended |

| Dimensions & Weight | 12-inch class front module footprint; matches original DYTP123A cutout and bezel form factor |

Application Fields

You’ll typically find the DYTP123A on operator panels in process and utility environments—power generation, oil & gas, petrochemicals, water/wastewater, metals, marine, and OEM machinery. Common use cases include:

- Restoring touch functionality on ABB HMIs that still display correctly but fail to register inputs.

- Field replacement after screen glass damage or yellowed backlight assemblies.

- Preventive spares strategy for facilities that must keep control rooms ready around the clock.

One thing I appreciate is how straightforward the swap tends to be: a maintenance supervisor told us they replaced two panels during a four-hour pit stop without touching the PLC program. That’s the kind of practical win plants look for.

Advantages & Value

- Reliability – Industrial-rated components for continuous operation in control rooms and cabinet-mounted HMIs.

- Compatibility – Built for ABB DYTP123A assemblies, so you keep existing wiring, CPU, and application files.

- Lower total cost – Replacing the touch panel typically costs far less than a complete HMI upgrade.

- Reduced downtime – Short installation time and no program migration keeps production on track.

- Support – We assist with identification and installation notes, plus the 365-day warranty gives peace of mind.

Installation & Maintenance

- Panel environment – Mount in a sealed cabinet that meets industrial standards; allow modest ventilation to avoid heat soak.

- Power safety – Isolate 24 VDC and follow lockout/tagout before opening the HMI assembly.

- ESD handling – Use a grounded wrist strap; avoid touching connector contacts and the active area of the touch screen.

- Wiring & grounding – Keep signal and power routes tidy; verify protective earth continuity to reduce EMI issues.

- Mounting – Do not over-tighten clips; compress the gasket evenly to maintain the IP front rating.

- Calibration – Run the ABB touch calibration routine after installation; it typically takes just a few minutes.

- Cleaning – Use a soft lint-free cloth with a small amount of isopropyl alcohol; avoid solvents and abrasive pads.

- Firmware – No firmware on the touch panel itself; keep the host HMI firmware up to date per plant policy.

Quality & Certifications

- Conformity: CE and RoHS alignment typical for ABB HMI assemblies (final compliance follows the complete device certification).

- Quality system: Manufactured under ISO 9001 processes.

- Warranty: 365 days against manufacturing defects.

You might notice that model code “61430001-TW” is a variant designation. If you’re replacing an existing panel, matching the suffix helps ensure connector and bezel compatibility. Share a photo of the nameplate if you want us to double-check fit before you order.

Reviews

There are no reviews yet.