Description

ABB GDB021BE01 (HIEE300766R0001) – Advant/MasterPiece Rack Module for System Expansion and Lifecycle Service

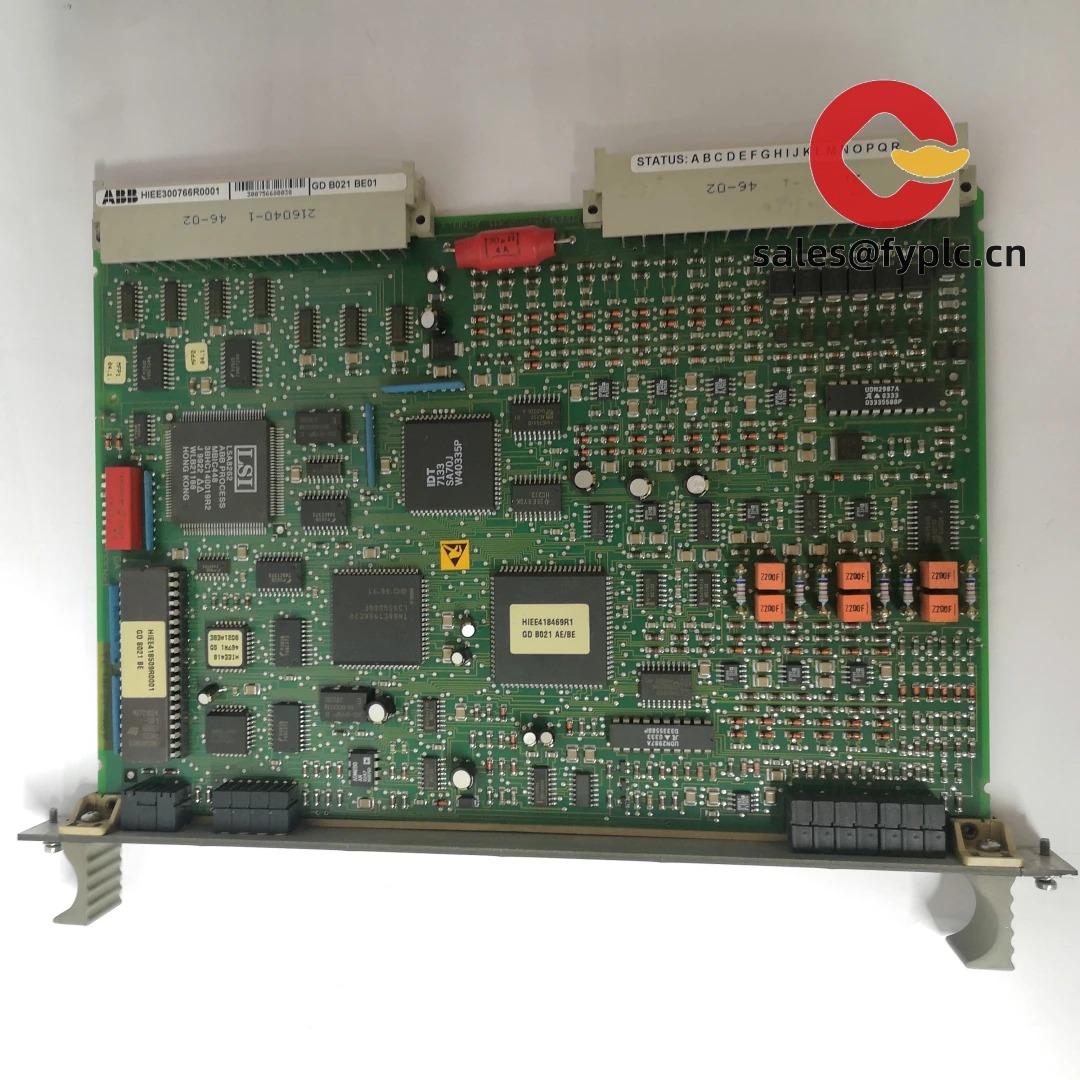

The ABB GDB021BE01 (type code: GD B021 BE01, order code: HIEE300766R0001) is a rack-mounted module used in ABB Advant/MasterPiece control system environments. From my experience, plants typically use this board to expand or maintain existing control segments without touching the running process — a practical way to extend system life or restore a faulty channel with minimal downtime. You might notice that it drops into the existing backplane and follows ABB’s familiar plug-in handling, so technicians don’t need extra tooling or re-training.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Pre-ship checks: functionality test, visual inspection, ESD-safe packing, traceable labeling

Key Features

- System compatibility – Designed for ABB Advant/MasterPiece-series racks, enabling drop-in replacement or expansion with minimal configuration.

- Backplane-powered – Draws low-voltage DC from the system backplane, reducing external wiring and simplifying cabinet layout.

- Stable operation – Industrial-grade build intended for continuous operation in control cabinets; in many cases, long service life with proper cooling and grounding.

- Lifecycle service friendly – Useful for plants keeping legacy Advant/MasterPiece assets productive without a costly full system migration.

- Fast swap design – Front-handle plug-in format typically shortens replacement time during planned shutdowns.

- Traceable part identification – Clear type code GD B021 BE01 and order code HIEE300766R0001 help verify procurement accuracy.

Technical Specifications

| Brand / Model | ABB GDB021BE01 (GD B021 BE01), Order Code: HIEE300766R0001 |

| System Compatibility | ABB Advant / MasterPiece-series control racks (legacy ABB DCS environments) |

| Product Type | Rack-mounted control system module (backplane interface module) |

| Power Requirements | Supplied via system backplane (low-voltage DC from cabinet PSU; no external power feed required) |

| Installation Method | Plug-in module; mounts into the appropriate ABB rack slot with front extraction handle |

| Operating Temperature | Typical control cabinet range 0…55 °C (follow the cabinet/rack specification for exact limits) |

| Communication / I/O | Backplane system-bus interface; field connections and addressing per rack configuration |

| HS Code (reference) | 8538.90 (Parts suitable for use with apparatus of heading 8537) |

Application Fields

This module is typically found in brownfield ABB DCS environments across:

- Power generation and utilities (unit control, balance-of-plant)

- Pulp & paper (machine sections, stock prep, chemical dosing)

- Oil & gas and petrochemical (auxiliary systems, interlocks, skids)

- Metals, mining, and cement (drives coordination, process auxiliaries)

- Food & beverage and pharmaceuticals where legacy ABB lines are maintained

Advantages & Value

- Risk reduction – Direct form/fit compatibility minimizes commissioning risk and helps avoid unplanned migration.

- Cost efficiency – In many cases, a single board swap restores availability at a fraction of a system upgrade.

- Short lead replacement – Stock-backed shipping options get maintenance teams the part faster.

- Technical support – Assistance with slot assignment, revision matching, and basic start-up checks.

One thing I appreciate is how predictable the installation is. A maintenance lead from a power plant told us they swapped the GDB021BE01 during a 2-hour window, verified status, and put the unit back online before their next shift change — no cabinet rewiring, no re-qualification of the loop.

Installation & Maintenance

- Cabinet conditions – Install in a clean, dry control cabinet with adequate ventilation. Maintain ambient within the rack’s specified temperature/humidity range.

- Wiring & grounding – Ensure reliable protective earth and shield termination practices to reduce noise on the system bus.

- Handling – Use ESD protection, power down the rack unless the maintenance manual explicitly allows hot-swap for the slot and revision.

- Commissioning – Match the module revision and parameters to your installed base. Document jumpers/switches if present and back up configuration before changes.

- Routine checks – Periodic visual inspection, connector cleaning, and verification of cabinet fans/filters. Keep firmware notes and spares labeled by revision.

Quality & Certifications

- Conformity – Typically CE-marked for industrial use; UL/cUL where applicable for the series.

- RoHS/Reach – Compliance depends on manufacturing lot and revision; we can verify per serial on request.

- Warranty – 365 days warranty coverage.

- Traceability – Model and order code labeling (GDB021BE01 / HIEE300766R0001) maintained on packaging and documents.

Related Accessories & Support

We can assist with compatible rack slots, backplane guidance, and alternative modules for the same Advant/MasterPiece segment when a specific revision is required. If you’re matching an existing installation, sharing the installed module photo and rack ID typically speeds up cross-checking.

Reviews

There are no reviews yet.