Description

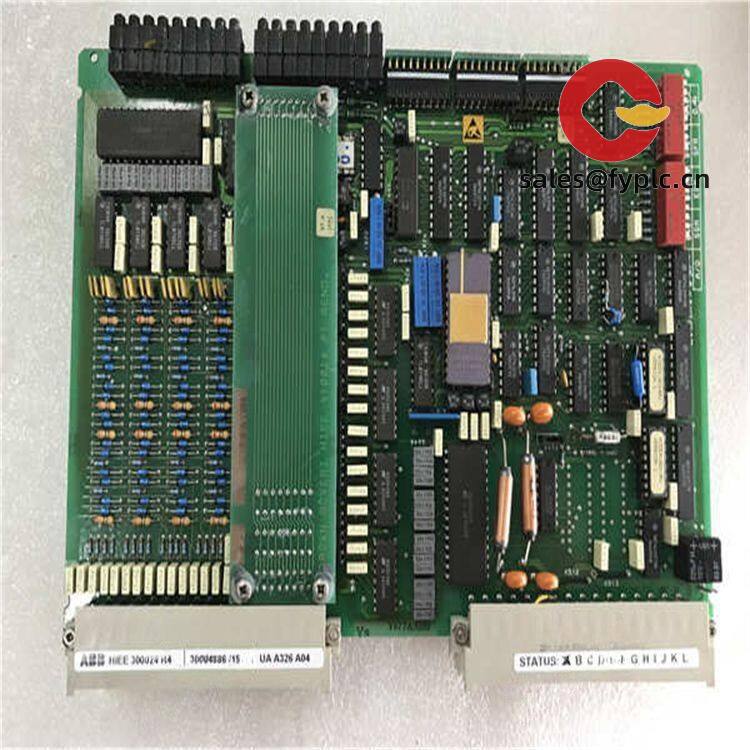

ABB HIEE300024R4 UAA326A04 – Analog I/O Interface Board for Advant/Advant Master DCS

The ABB HIEE300024R4 UAA326A04 is a plug-in I/O board that, in many cases, is used within ABB Advant / Advant Master controller racks as an analog interface module. From my experience with UAA-series boards, it typically handles analog signal conditioning and stable channel processing for process values like 4–20 mA or ±10 V. One thing I appreciate is how it fits as a drop-in replacement in legacy DCS bays—minimal disruption, fast swap, and no need to touch field wiring if the termination unit is kept the same.

You might notice that these ABB UAA modules are favored in plant life-extension projects—power, pulp & paper, oil & gas—because they’re reliable and preserve existing control logic. It seems to be the practical choice when you need to keep a mature Advant system running with predictable performance and low integration risk.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express shipping: FedEx, UPS, DHL

Key Features

- Advant/Advant Master compatibility: Designed for use in ABB DCS racks; plug-in installation keeps retrofit time short.

- Analog signal handling: Typically supports standard industrial ranges (e.g., 4–20 mA, ±10 V) with stable conversion for process values.

- Backplane-powered: No external power supply; the module draws regulated DC from the system backplane.

- Channel diagnostics: Front LED indications and status checks help technicians trace faults quickly during commissioning.

- Robust design for plant environments: Built for cabinet installation; dependable operation under typical industrial temperature and vibration.

- Drop-in replacement: Keeps existing field wiring via the original termination unit, reducing shutdown duration.

Technical Specifications

| Brand / Model | ABB HIEE300024R4 / UAA326A04 |

| HS Code | 853890 (Parts for industrial control equipment) |

| Power Requirements | Backplane-supplied DC; no external power connection (typical for ABB Advant boards) |

| Operating Temperature | 0 to 55 °C (typical cabinet-mounted operation) |

| Signal Input/Output Types | Analog interface (e.g., 4–20 mA / ±10 V) depending on system configuration within the Advant rack |

| Communication Interfaces | Advant system backplane bus; front connection via associated termination unit |

| Installation Method | Plug-in module for ABB Advant/Advant Master racks; cabinet mounting |

Application Fields

Plants that rely on ABB Advant or Advant Master DCS typically use the UAA-series boards where stable analog acquisition or output is required. Common deployments include:

- Power generation (boiler controls, turbine auxiliaries, balance-of-plant loops)

- Pulp & paper (stock preparation, drying, steam and condensate control)

- Oil & gas (utilities, compressors, tank farms, blending)

- Chemicals and specialty process lines (temperature, pressure, and flow loops)

- Metals & mining (cooling systems, lubrication skids, utilities)

A maintenance manager told us, “Swapping a UAA board took under an hour during a planned stop—no rewiring, just reseat and verify values. That saved us a whole shift.”

Advantages & Value

- Reliability: Proven field performance; stable readings reduce nuisance trips and tuning drift.

- Compatibility: Works within the intended ABB rack and backplane—no software rewrite in most cases.

- Cost control: Extends the lifecycle of existing Advant assets, deferring large-scale migrations.

- Serviceability: Fast module replacement and straightforward fault isolation through front indications.

- Technical support: Guidance on firmware revisions, rack slotting, and termination unit matching.

Installation & Maintenance

- Cabinet & environment: Install in a clean, ventilated control cabinet; maintain ambient 0–55 °C and avoid condensation.

- Wiring & grounding: Use the approved termination unit; maintain shield continuity and proper instrument grounding to minimize noise.

- ESD handling: Use wrist straps and antistatic packaging; avoid touching components during insertion.

- Commissioning: Confirm slot address, verify analog scaling, and check diagnostics LEDs before returning to service.

- Maintenance: Periodically inspect connectors, clean dust with dry air, and verify loop calibration against known references.

- Firmware/compatibility: Match module firmware and rack controller revisions where applicable to maintain system stability.

Quality & Certifications

- Certifications: Typically CE; many deployments also observe UL and RoHS requirements depending on production batch and region.

- Warranty: 365 days against functional defects under normal use.

If you’re consolidating spares or planning a targeted Advant upgrade, this UAA326A04 module is a practical choice—keeps the DCS architecture intact while restoring dependable analog handling. I’m happy to help double-check rack compatibility and the matching termination unit before you place the order.

Reviews

There are no reviews yet.