Description

ABB IGCT Module 3BHL000389P0101 – High‑reliability power switching for medium‑voltage drives and converters

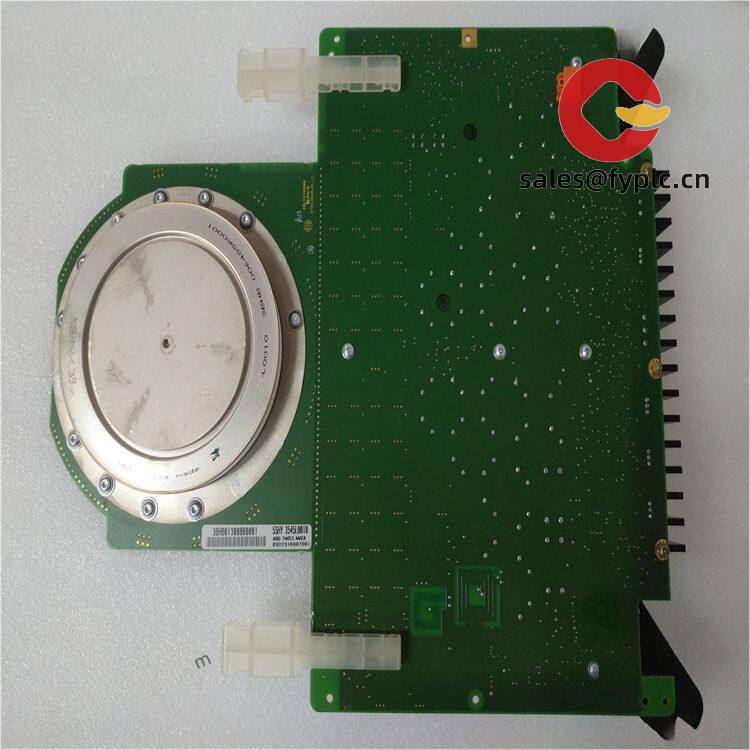

ABB’s 3BHL000389P0101 is an IGCT (Integrated Gate-Commutated Thyristor) module used in ABB medium‑voltage power stacks—typically in industrial drives and grid converters where low losses and rugged cycling are essential. You might notice that the 3BHL… code is ABB’s service/spare identifier, which helps ensure drop‑in mechanical and electrical compatibility with existing ABB power cells. From my experience, this part is commonly found in ABB MV drive families (such as ACS1000/ACS6000) and similar converter platforms that rely on press‑pack IGCT technology for long service life and fast safe turn‑off.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- IGCT technology for MV duty: Low conduction loss and strong turn‑off capability—well suited to continuous heavy loads and frequent cycling.

- Press‑pack construction: No wire bonds; the pressure contact design typically offers excellent thermal paths and predictable failure modes.

- Form‑fit replacement: Delivered to match ABB power stack interfaces so downtime is minimized during maintenance.

- Gate unit compatibility: Works with the corresponding ABB gate unit for controlled turn‑on/off, often fiber‑isolated at the driver level.

- Rugged surge performance: Designed for industrial environments where line disturbances and transient stresses are not unusual.

- Traceability: ABB spare coding and serial tracking help with fleet maintenance records and lifecycle planning.

Technical Specifications

| Brand / Model | ABB / 3BHL000389P0101 (IGCT Module) |

| HS Code | 8541.30 (Thyristors and similar semiconductor devices) |

| Device Type | Integrated Gate‑Commutated Thyristor (press‑pack power semiconductor) |

| Power Requirements | None for the device itself; external ABB gate unit requires its own low‑voltage supply (typically 24 VDC) |

| Signal I/O | Gate and cathode interface via matching ABB gate unit; main power path via press‑pack anode/cathode contacts |

| Communication Interfaces | None on the device (control is at the gate unit level) |

| Installation Method | Press‑pack clamped between heat sink/busbar plates with calibrated force; use approved clamp set and thermal interface material |

| Typical Use | ABB medium‑voltage drives and converter power stacks |

Application Fields

This IGCT module is typically used in:

- Medium‑voltage AC drives for fans, compressors, mills, and pumps in cement, mining, metals, and oil & gas

- MV propulsion and large test benches where continuous operation and low thermal stress are key

- Grid‑connected converters (e.g., SVC/STATCOM) that benefit from fast, robust switching devices

One thing I appreciate is how IGCT‑based stacks tend to run cooler at high power compared with similar IGBT solutions, which in many cases translates to better efficiency and fewer thermal‑related service calls.

Advantages & Value

- Compatibility you can plan around: ABB spare coding helps avoid form/fit issues in legacy MV stacks.

- Lower lifecycle cost: Replacing a single module is often far more economical than swapping an entire power cell.

- High reliability under stress: Press‑pack IGCTs handle cycling and overloads gracefully when properly clamped and cooled.

- Service support: Technical guidance on handling, clamping force, and gate unit checks to reduce commissioning risk.

Installation & Maintenance

- Environment: Mount inside a sealed or filtered cabinet; keep dust and moisture away from press‑pack surfaces. Provide adequate ventilation or liquid cooling per the stack design.

- Handling: Treat as an ESD‑sensitive component; avoid touching mating faces. Keep protective caps on until final assembly.

- Heat transfer: Clean and flat heat sink plates; apply a thin, uniform thermal paste layer. Do not over‑apply.

- Clamping: Use an approved clamp set or hydraulic fixture to reach the specified force. Re‑check mechanical fasteners after initial thermal cycles.

- Wiring: Verify busbar clearances and torque. Ensure the correct ABB gate unit type and fiber/electrical interface are used as specified for the stack.

- Commissioning: Discharge the DC link fully before work. Run the drive’s gate test/self‑check. Monitor device temperature on first runs.

- Routine care: Periodically inspect filters, clean airflow paths, and review thermal scans. Firmware updates on the drive control (when recommended) can improve gate timing and protection behavior.

Supporting Components (often paired with this IGCT)

- ABB IGCT Gate Unit (GU): Matching driver with isolated control (often fiber‑optic at the control side) to deliver the required gate current profile.

- Press‑pack clamping set: Calibrated hardware to achieve the correct contact pressure and maintain it over thermal cycling.

- Snubber network: Snubber capacitor and resistor assembly to manage dv/dt and equalize voltage sharing in series stacks.

- Heat sink assembly: Air or liquid‑cooled plates sized for the device’s losses and the cabinet’s thermal budget.

If you share your stack code or drive typeplate, we can cross‑check the exact gate unit version and clamping kit that match 3BHL000389P0101. It seems to save a lot of back‑and‑forth during a shutdown.

Quality & Certifications

- Manufacturing quality: Produced under ABB’s quality system (ISO 9001)

- RoHS: Compliant in most cases (standard component exemptions may apply for high‑reliability power devices)

- CE/UL: Not typically applicable to individual semiconductor devices; final equipment certification remains at the system level

- Warranty: 365 days from delivery

Reviews

There are no reviews yet.