Description

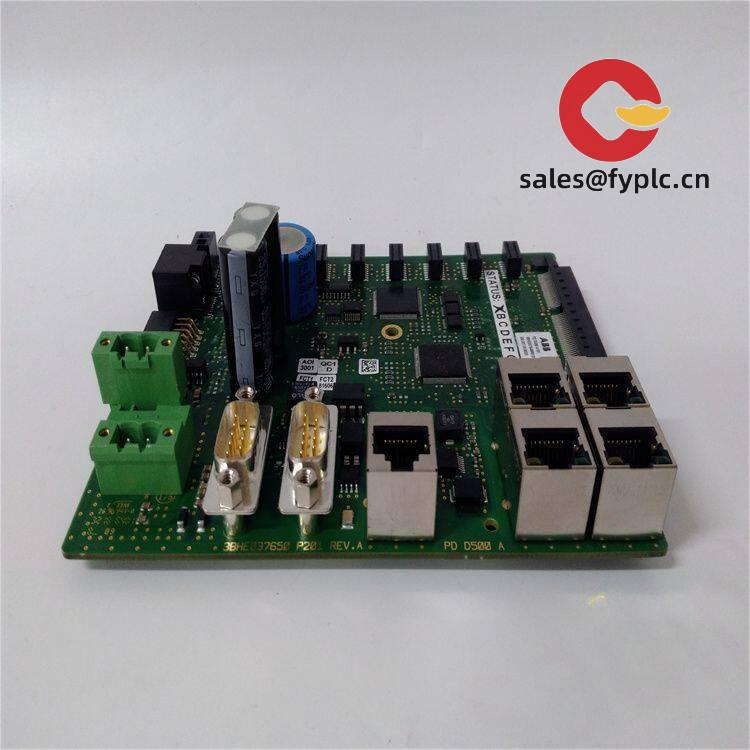

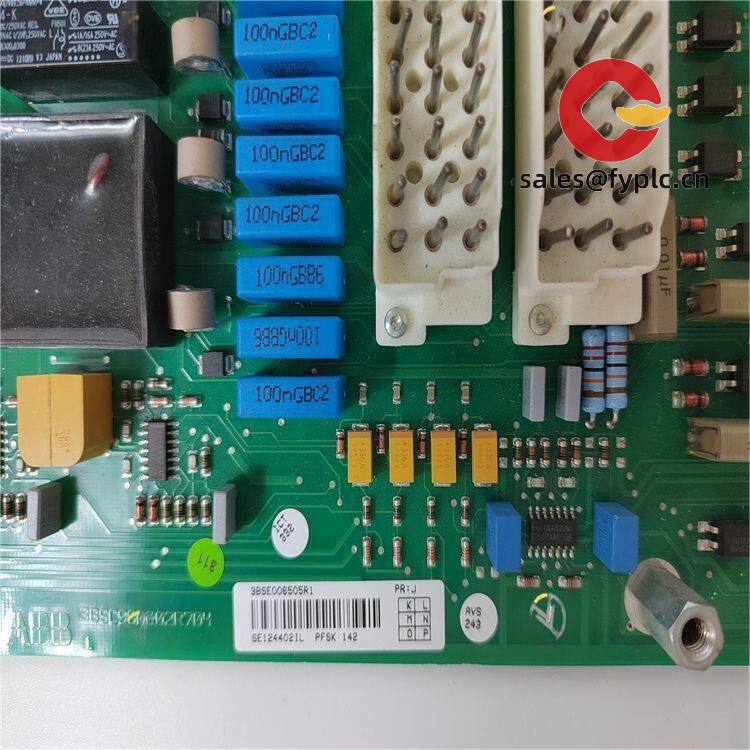

ABB PFSK142 (3BSE006505R1) – Modular interface/signal conditioning module for ABB 800xA/Advant systems

The ABB PFSK142, order code 3BSE006505R1, is a compact industrial control module typically used within ABB’s 800xA/Advant architecture for interface and signal conditioning tasks. From my experience, this unit is chosen when engineers want a neat, cabinet-friendly way to bridge field wiring and the controller-side system bus, while keeping noise immunity and long-term reliability in check. You might notice that it fits the modular approach ABB is known for—quick to mount, easy to swap, and predictable in day‑to‑day operation.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Designed for ABB 800xA/Advant environments: Seamlessly integrates into existing ABB cabinets and modular bases, reducing engineering time.

- Stable 24 VDC operation (typical): Runs off standard control-cabinet power for predictable performance in most plants.

- DIN‑rail friendly footprint: Compact, modular mechanics that make panel layout straightforward.

- Robust signal handling: Suitable for low‑voltage logic and field signal interfacing with attention to EMC and cabinet noise.

- Status indication (where applicable): Visual cues help speed up commissioning and troubleshooting.

- Serviceable design: Hot‑swap or quick replacement approach in many cabinets, helping to minimize downtime.

Technical Specifications

| Brand / Model | ABB PFSK142 (3BSE006505R1) |

| HS Code | 8537.10 (Boards/panels for electric control or distribution) |

| Power Requirements | 24 VDC nominal (typical control cabinet supply) |

| Operating Temperature | 0…+55 °C (typical industrial cabinet conditions) |

| Signal I/O Types | Low‑voltage logic/field signal interfacing; isolation and filtering as per ABB system design |

| Communication Interfaces | Internal system/backplane interfacing within ABB 800xA/Advant; external fieldbus handled by dedicated ABB comm modules in the same system |

| Installation Method | DIN‑rail cabinet mounting with compatible ABB bases/terminal units |

| Form Factor | Compact modular unit; cabinet‑depth friendly |

Application Fields

The PFSK142 is typically applied in process automation cabinets where ABB AC 800M/Advant controllers and S800‑style modular components are deployed. It seems to be a sensible pick for:

- Refining and chemicals – stable field wiring interface in noisy EMC environments.

- Power generation – turbine auxiliaries and BOP cabinets where uptime matters.

- Pulp & paper – distributed I/O rooms with strict space and maintenance routines.

- Pharma & food – clean cabinets needing predictable, documented module behavior.

- Water & wastewater – standardized panels across remote stations.

Advantages & Value

- Reliability: Built for continuous service; fewer nuisance trips and fewer “mystery” wiring issues.

- Compatibility: Plays nicely with ABB’s modular ecosystem, lowering design and commissioning effort.

- Lifecycle support: ABB documentation and spares availability tend to be strong for this family.

- Cost control: Quick swap and straightforward mounting help reduce downtime costs.

- Engineering simplicity: Predictable interfaces mean less custom work in the panel.

A maintenance lead at a power plant told us they liked that “it just drops in with the rest of the ABB gear, wiring is tidy, and we don’t waste time hunting for adapters.”

Installation & Maintenance

- Cabinet environment: Install in a dry, vibration‑controlled enclosure with adequate ventilation; keep ambient within 0…+55 °C.

- Power & grounding: Use clean 24 VDC with proper grounding and shield terminations to minimize EMC issues.

- Wiring: Follow ABB terminal/base recommendations; separate power and signal routing where possible.

- Safety: De‑energize before insertion/removal unless system documentation expressly supports hot‑swap.

- Routine maintenance: Inspect terminal tightness every 6–12 months, clean dust with dry air, and keep firmware/config records aligned with site standards.

- Spares strategy: Stock at least one unit per critical cabinet to shorten recovery time.

Quality & Certifications

- CE marking: Conforms to applicable EMC and LVD requirements for industrial control equipment.

- UL/CSA: Commonly available for ABB control modules used in North American panels (model‑specific).

- RoHS: RoHS compliance in most regions.

- Manufacturing system: Produced under ABB’s ISO 9001 quality management.

- Warranty: 12 months (365 days) from shipment.

Related/Complementary Components (typical)

- AC 800M controller series for main CPU and task execution.

- S800 I/O terminal units (TU8xx) for field wiring and backplane connection.

- Communication modules (e.g., CI854A for PROFIBUS DP) when fieldbus is required.

- 24 VDC cabinet power supplies and redundancy modules for uptime.

Note: Specific behaviors and channel characteristics can vary by system configuration. If you share your cabinet layout or a BOM, we can validate exact compatibility and suggest the cleanest wiring scheme for the PFSK142 in your application.

Reviews

There are no reviews yet.