Description

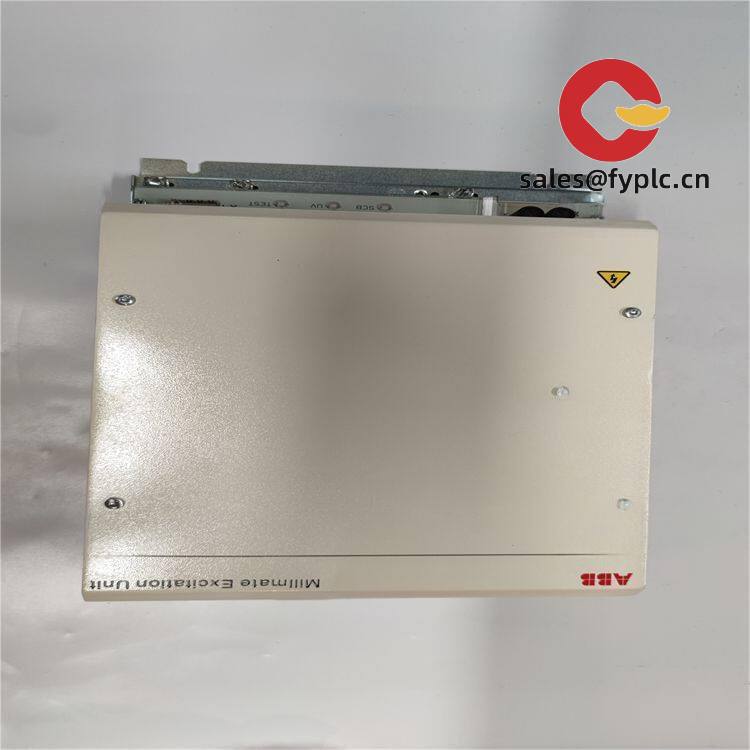

ABB PFVI401 (3BSE018732R1) – Interface Module for ABB Distributed Control Systems

The ABB PFVI401, part number 3BSE018732R1, is an original ABB interface module commonly used within ABB DCS environments (such as 800xA/Advant/Industrial IT families) to expand connectivity and system integration. From my experience, this module is typically selected as a form-fit-function replacement when plants want to keep legacy cabinets running reliably while integrating newer devices or replacing aging boards without re-engineering the whole panel.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: Typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Original ABB spare with model-match – Designed as PFVI401 3BSE018732R1 for straightforward replacement in existing cabinets.

- Backplane-powered design – In many cases, no external power wiring is required; it draws power from the host system rack.

- Stable integration in ABB DCS – Works within ABB control environments where predictable behavior and lifecycle continuity matter.

- Maintenance-friendly – Clear labeling and ABB diagnostics support help reduce troubleshooting time during turnarounds.

- Form-fit-function continuity – Helps avoid requalification or re-cabling that often comes with third-party substitutes.

Technical Specifications

| Brand / Model | ABB PFVI401 (3BSE018732R1) |

| HS Code | 853890 (Parts for electrical control equipment) |

| Power Requirements | Backplane powered within ABB system rack (no separate external PSU in typical installations) |

| Communication Interfaces | Designed for ABB system bus integration; interface specifics per PFVI401 documentation |

| Installation Method | Installed in the appropriate ABB system base/rack within a control cabinet |

Application Fields

You’ll typically find the PFVI401 in process industries where ABB DCS is standard—refining, chemicals, power generation, pulp & paper, and water treatment. Plants use it to keep existing I/O and subsystem links operational while they standardize upgrades project-by-project. One maintenance manager at a chemical site told us this module “dropped in and synced with our existing controls with zero rewiring,” which seems to be the sweet spot when uptime is critical and shutdown windows are tight.

Advantages & Value

- Reliability: Original ABB hardware aligned with system firmware behavior helps avoid intermittent faults.

- Compatibility: Fits established ABB architectures, reducing integration risk versus non-OEM parts.

- Cost control: Minimizes engineering hours and prevents unplanned downtime—often the biggest cost driver.

- Supportability: Documentation, spares strategy, and field-proven use make maintenance predictable.

Installation & Maintenance

- Cabinet environment: Use a clean, dry, ventilated control cabinet. Keep typical DCS clearances around the module for airflow.

- Wiring & grounding: Follow ABB grounding and shielding practices; maintain proper backplane seating and locking tabs.

- Handling: ESD-safe handling is essential. Seat the module with power isolated unless the system explicitly supports hot-swap.

- Routine checks: Inspect connectors during planned outages, clean dust with dry air, and verify firmware compatibility during upgrades.

- Documentation: Refer to ABB PFVI401 service notes for exact interface details and firmware pairing recommendations.

Quality & Certifications

- Certifications: CE compliant; RoHS aligned; manufacturing under ISO 9001 quality systems (typical for ABB industrial modules).

- Warranty: 365-day warranty coverage from delivery.

If you’re standardizing on ABB hardware and need a like-for-like PFVI401 replacement, this unit is a practical choice. You might notice the real benefit during your next shutdown: fewer surprises, faster commissioning, and no last-minute wiring changes.

Reviews

There are no reviews yet.