Description

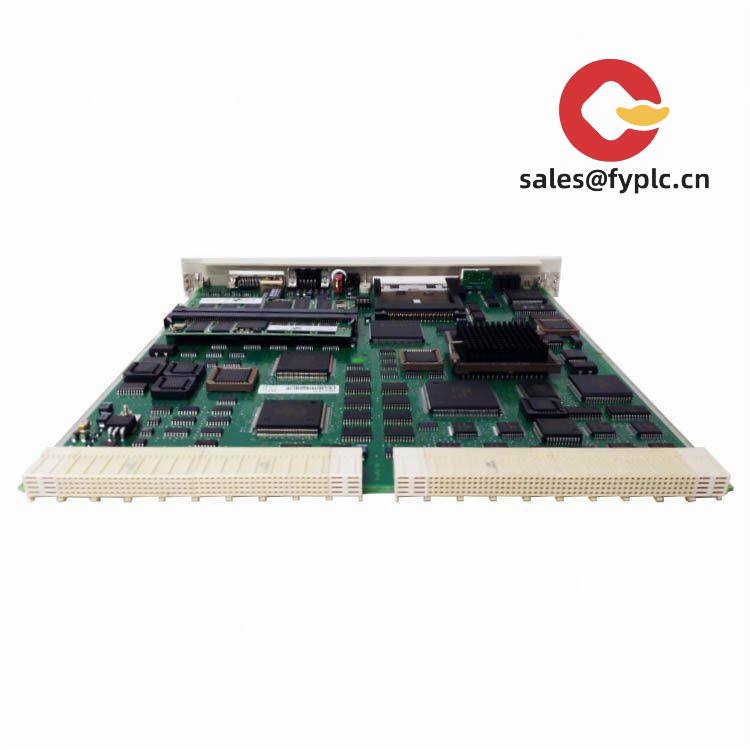

ABB PM510V16 3BSE008358R1 – Processor Module for Advant Controller Systems

The ABB PM510V16 (3BSE008358R1) is a processor module widely used in legacy ABB Advant Controller installations where stable cycle times and long-term availability matter more than flashy features. From my experience, plants keep these running because they’re dependable, easy to maintain in a rack environment, and integrate cleanly with existing ABB I/O via the system backplane and approved interface units. The V16 memory variant is typically selected for medium-sized applications where you want room for sequence control, basic analog loops, and alarm handling without stretching the CPU.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Processor module for Advant Controller racks – Fits designated CPU slot for stable, deterministic control cycles.

- V16 memory variant – Typically used for mid-scale logic, interlocks, and basic regulatory control without resource strain.

- Backplane-powered – Draws DC power from the system power unit; simplifies field wiring and service.

- Modular I/O via system bus – Uses remote and rack-mounted I/O through approved ABB interfaces; no onboard field I/O.

- Service-friendly – Hot-swap capability depends on rack/system design; most sites report quick swap and recovery.

- Long lifecycle support – Suited for modernization projects where you replace the CPU while keeping I/O and wiring intact.

Technical Specifications

| Brand / Model | ABB PM510V16 (3BSE008358R1) |

| Product Type | Processor Module for Advant Controller systems |

| HS Code | 8537.10 (Programmable controllers; for a voltage not exceeding 1000 V) |

| Power Requirements | Backplane-supplied DC power from system power unit; typical low-watt draw for CPU-class modules |

| Operating Temperature | 0 to 55 °C (typical for rack-mounted ABB controller modules) |

| Signal I/O Types | No direct field I/O on CPU; uses remote/rack I/O through system bus and interface units |

| Communication Interfaces | System backplane bus; fieldbus and Ethernet connectivity available via corresponding interface modules/gateways (depending on installation) |

| Installation Method | Plug-in module for the dedicated processor slot in an Advant Controller rack |

| Dimensions & Weight | Compact rack-format module; refer to rack manual for slot pitch and mass specifics |

Application Fields

You’ll typically see the PM510V16 in brownfield upgrades and life-cycle extensions where the base Advant architecture remains in place:

- Power generation balance-of-plant logic, turbine auxiliaries, and fuel handling

- Chemical and petrochemical unit operations with SIF interlocks handled upstream

- Pulp & paper stock prep, machine auxiliaries, drives coordination

- Water/wastewater plant controls, pump stations, and filtration skids

- Metals and mining utilities, crushers/stackers, and material handling

Advantages & Value

- Reliability in mature systems – Keeps existing racks, wiring, and field I/O; reduces outage time and engineering effort.

- Compatibility – Works within Advant Controller infrastructure; fieldbuses can be maintained through existing interface modules.

- Cost control – In many cases, a CPU refresh avoids a full DCS/PLC migration, saving CAPEX and commissioning hours.

- Serviceability – Straightforward swap procedures; most sites report fast return to operation after module replacement.

- Lifecycle extension – Ideal for phased modernization where you upgrade communications and HMI later on.

Installation & Maintenance

- Cabinet environment – Mount in the specified Advant controller rack; maintain ambient 0–55 °C with adequate ventilation and minimal dust.

- Power and grounding – Use the designated system power unit and grounding scheme; avoid shared returns that create noise on the backplane.

- Wiring practices – Keep signal and power separated; verify fieldbus terminations and shield continuity if interface modules are present.

- Firmware and backups – Keep a validated firmware/application image; schedule backups after any engineering change.

- Routine maintenance – Inspect connectors and retention clips; clean contacts during planned outages; check event logs for watchdog resets.

- ESD handling – Treat as a sensitive electronic assembly; use ESD protection during installation or service.

Quality & Certifications

- Manufacturer quality systems: typically aligned to ISO 9001

- Regional safety/EMC approvals: commonly CE compliant for industrial environments

- RoHS status: many Advant-era modules predate current RoHS scopes; site-specific compliance review is recommended

- Warranty: 365 days replacement warranty as part of our supply program

Common Supporting Components (for planning)

You might notice that most installations pair the PM510V16 with standard Advant power and I/O building blocks. Typical companions include:

- Advant controller rack and system power unit – Provides the regulated backplane DC and slot infrastructure.

- Fieldbus/interface modules – Depending on site design, gateways to plant networks (e.g., PROFIBUS, Ethernet-based links) are added at the rack or system level.

- Remote and rack I/O – Digital/analog I/O modules via the system bus; keeps existing marshalling intact during CPU replacement.

Reviews

There are no reviews yet.