Description

ABB PM803F (3BDH000530R1) – CPU module for Freelance AC 800F process automation

The ABB PM803F is the performance CPU for the Freelance AC 800F DCS platform. From my experience, it’s the sweet spot when you need a reliable, fieldbus-centric controller with Ethernet connectivity and broad protocol support—without getting overly complex. The order code 3BDH000530R1 corresponds to the PM803F processing unit that runs your control strategy in Control Builder F and connects upstream via Ethernet while interfacing downstream I/O over fieldbuses like PROFIBUS, FOUNDATION Fieldbus, HART, and Modbus (with the appropriate interfaces).

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Designed for ABB Freelance AC 800F – Runs control applications engineered in Control Builder F; drop-in fit for existing AC 800F systems.

- Industrial Ethernet connectivity – Typically 10/100BASE‑T ports for engineering, HMI/SCADA, and plant network integration.

- Fieldbus-oriented architecture – Integrates PROFIBUS DP/PA, FOUNDATION Fieldbus H1, HART, and Modbus (TCP/RTU) via interface modules.

- Robust 24 VDC operation – Stable performance on standard industrial 24 VDC power in most cases.

- No onboard I/O – Uses remote I/O over fieldbus; simplifies cabinet wiring and scales easily.

- Diagnostics and status LEDs – You might notice quicker commissioning thanks to clear front-panel indicators and service access.

- Redundancy-ready architecture – Many systems deploy PM803F in redundant pairs for higher availability (subject to system configuration and firmware).

Technical Specifications

| Brand / Model | ABB PM803F – Order code 3BDH000530R1 |

| HS Code (suggested) | 8537.10 – Programmable controllers |

| Power Requirements | 24 VDC nominal (typically 18–32 VDC) |

| Operating Temperature | 0 to +55 °C (controller); relative humidity 5–95% non‑condensing |

| Signal I/O Types | No onboard I/O; remote I/O via fieldbus (e.g., PROFIBUS DP/PA, FF H1, HART, Modbus) |

| Communication Interfaces | Ethernet 10/100BASE‑T; service serial port (RS‑232/RS‑485); optional fieldbus interfaces as required |

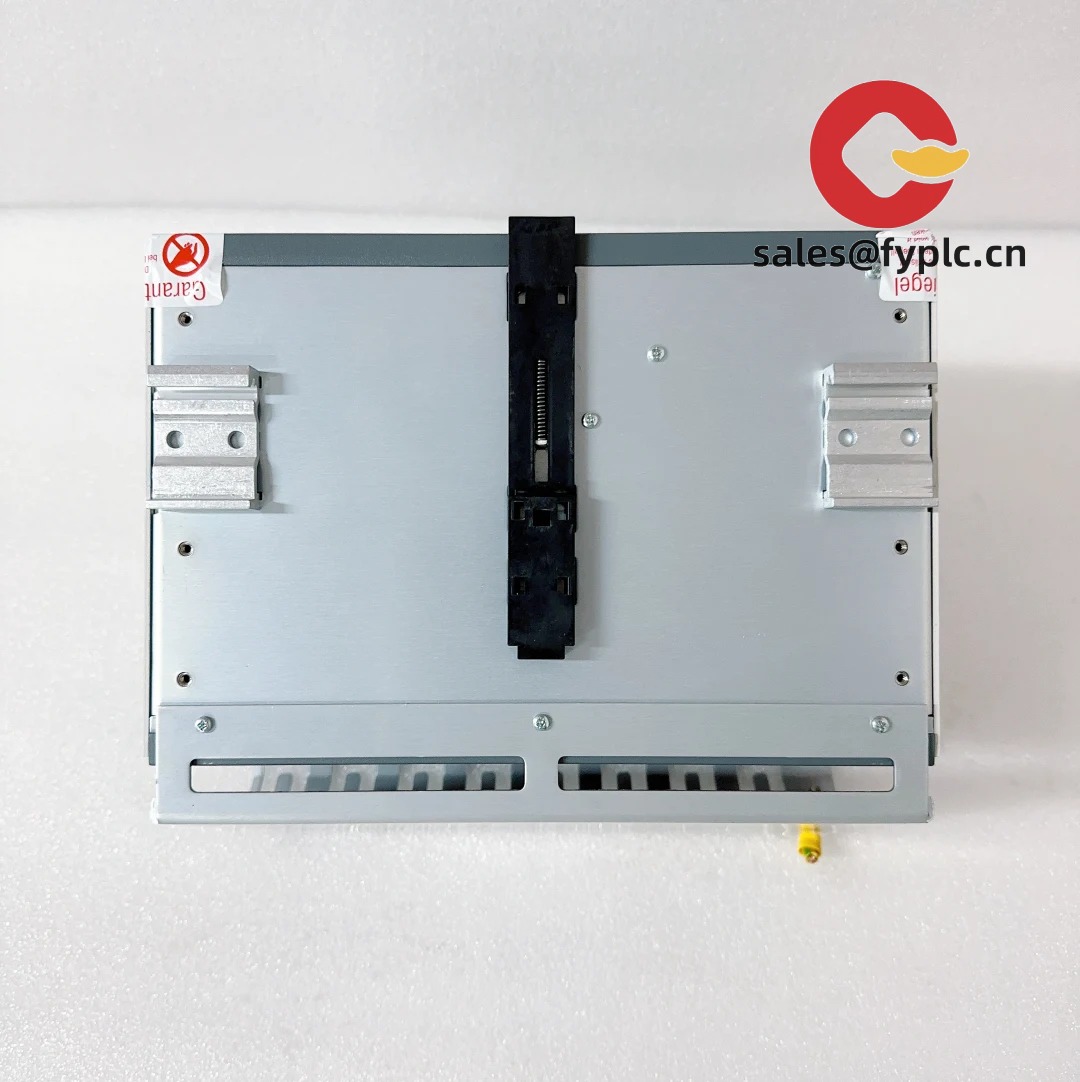

| Installation Method | DIN‑rail mounting in a ventilated control cabinet |

| Dimensions & Weight | Compact DIN‑rail module; typically under 1.0 kg (final footprint depends on interface configuration) |

Application Fields

The PM803F sits comfortably in small to mid‑size process units and scales up with fieldbus I/O. I typically see it used in:

- Chemical and specialty chemicals – batch control, reactor temperature/pressure loops, skid integration

- Oil & gas (upstream and terminals) – compressor packages, produced water treatment, metering skids

- Power and utilities – water treatment, boiler islands, auxiliary balance‑of‑plant

- Food & beverage – CIP/SIP skids, blending, utilities monitoring

- Pharma – clean utilities and packaging where FOUNDATION Fieldbus/HART diagnostics help maintenance

Advantages & Value

- Reliability – Proven AC 800F hardware; stable 24 VDC operation and solid fieldbus stack.

- Compatibility – Works with common plant protocols; easy to tie into existing PROFIBUS/FF networks.

- Lifecycle cost – Fieldbus I/O reduces marshalling and wiring; spares stocking is straightforward.

- Scalability – Add interfaces as a project grows; no need to replace the CPU for moderate expansions.

- Support – Engineering with Control Builder F is consistent across Freelance versions, which typically shortens FAT/SAT time.

Installation & Maintenance

- Cabinet & mounting – Install on 35 mm DIN rail inside a clean, ventilated enclosure. Keep ambient 0…+55 °C and avoid direct heat sources.

- Power & grounding – Feed regulated 24 VDC with proper fusing. Use a low‑impedance protective earth; bond cabinet doors and DIN rails.

- Networking – Use shielded CAT5e/6 for Ethernet; segregate control from IT traffic where possible. Managed switches with VLAN/RSTP are often preferred.

- Fieldbus wiring – Follow bus‑specific rules (termination, segment lengths, spur limits). Maintain segment power conditioners for FF/PA networks.

- Safety & ESD – Power down before inserting/removing modules. Use ESD protection when handling the CPU and memory media.

- Routine care – Periodically back up the application to the engineering station and memory media, review diagnostics, and keep firmware aligned with your plant’s validated version.

- Spares – It appears that keeping one PM803F and a set of the used fieldbus interfaces on hand minimizes downtime during unplanned events.

Common Supporting Components

- S800 I/O family (e.g., DI810 digital input, AI810 analog input, AO810 analog output) for remote I/O over fieldbus—compact footprint and widely used.

- Managed industrial Ethernet switch for controller/HMI networks with redundancy (RSTP/MRP) and VLAN segmentation.

- Memory media for application backup and restore; useful for fast controller replacement during maintenance.

- Fieldbus power conditioners/segment couplers for FOUNDATION Fieldbus H1 or PROFIBUS PA segments to ensure stable communication and device power.

Quality & Certifications

- Typically CE compliant for EMC and safety; RoHS alignment on most current builds

- UL/cUL listing is commonly available for ABB controllers used in North America

- Manufactured under ISO 9001 quality systems

- Manufacturer’s standard warranty applies; our supply includes a 365‑day warranty

From a recent user on a wastewater upgrade: “Swapping in a PM803F on our AC 800F cabinet was straightforward—kept the PROFIBUS I/O, downloaded from Control Builder F, and were trending live within the shift.”

Reviews

There are no reviews yet.