Description

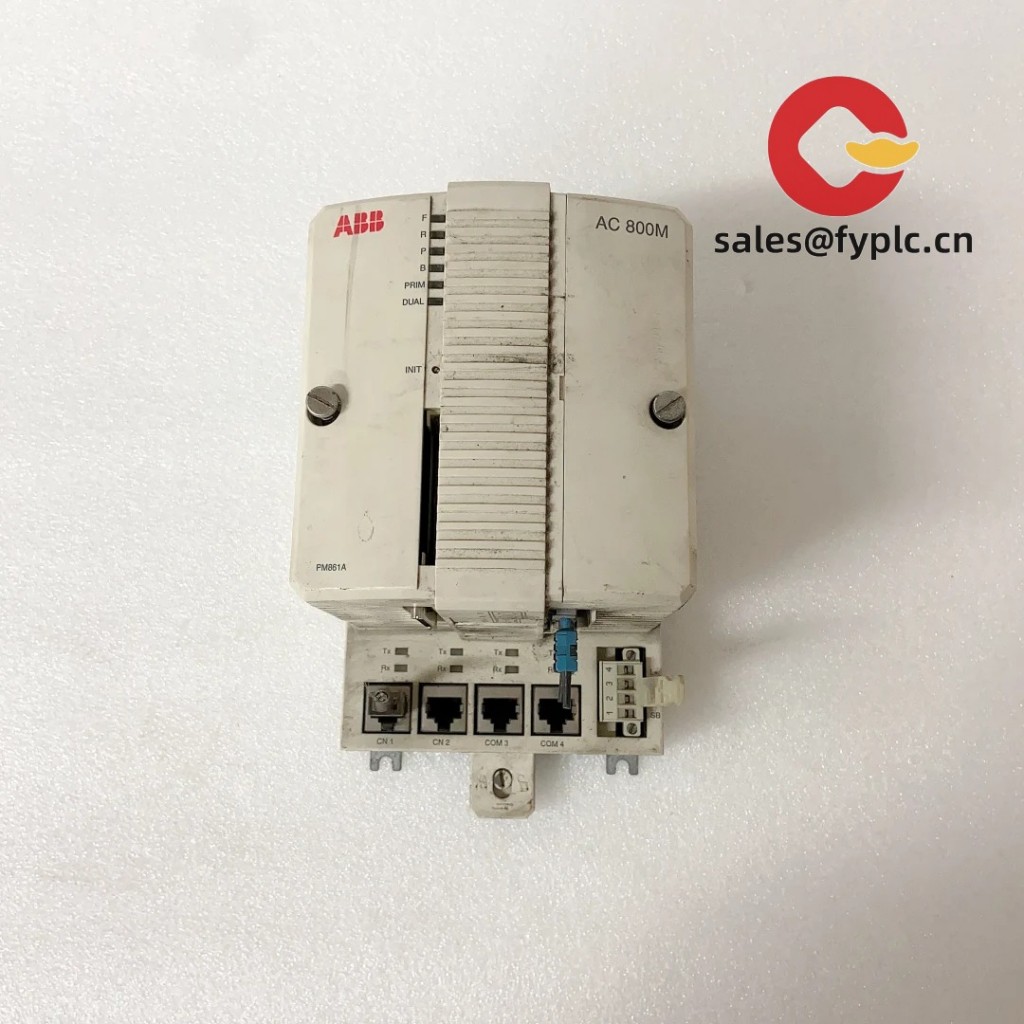

ABB PM856AK01 (3BSE066490R1) – AC 800M CPU Kit for Reliable Mid-Range Process Control

The ABB PM856AK01 is the kit version of the PM856A controller in the AC 800M family, typically selected for continuous process applications that need dependable performance, controller redundancy options, and straightforward integration with S800 I/O. From my experience, this model hits a sweet spot for plants modernizing legacy DCS areas or scaling up a line without jumping to the highest-end CPUs. The “K01” kit designation commonly indicates the controller is supplied with the standard accessories needed to get you configured quickly.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- AC 800M platform compatibility – Works seamlessly with S800 I/O and common fieldbus interfaces for brownfield and greenfield projects.

- Mid-range performance – Well-suited for medium to large control applications with stable scan times and ample application memory in many cases.

- Redundancy-ready – Supports controller redundancy when paired with a second PM856A and redundancy accessories, helping reduce unplanned downtime.

- Dual Ethernet ports – Two 10/100Base‑T RJ45 ports for control networks, engineering access, and integration with plant systems.

- CEX-bus expansion – Add communication modules (e.g., PROFIBUS DP, Modbus TCP) without rewriting your architecture.

- Service-friendly – Front diagnostics LEDs and a service port make troubleshooting and firmware handling straightforward.

- Time synchronization – SNTP/NTP support typically used for event sequencing and multi-controller alignment.

- Engineered with Control Builder M – Part of ABB’s Automation Builder toolchain, streamlining project configuration and lifecycle maintenance.

Technical Specifications

| Brand / Model | ABB PM856AK01 (Order Code: 3BSE066490R1), AC 800M Controller CPU Kit |

| HS Code | 8537.10 (For a voltage not exceeding 1,000 V) |

| Power Requirements | 24 V DC supplied via AC 800M base unit (typ. system power feed). Use a stabilized SELV/PELV source. |

| Dimensions & Weight | Single AC 800M CPU slot form factor; typical module weight approx. 0.6–0.8 kg (varies with kit contents). |

| Operating Temperature | 0 to +55 °C (cabinet installation in a controlled environment is recommended) |

| Signal Input/Output Types | Digital and analog I/O via S800/S900 I/O families (local or remote) through supported fieldbus interfaces. |

| Communication Interfaces | 2× 10/100Base‑T Ethernet (RJ45), 1× RS‑232 service port; CEX‑bus for add-on modules (e.g., PROFIBUS DP, Modbus TCP). |

| Time Synchronization | SNTP/NTP (plant time server recommended for multi-controller systems) |

| Redundancy | Controller redundancy supported with a second PM856A and redundancy accessories (typical AC 800M HA setup). |

| Installation Method | DIN-rail cabinet mounting using the designated AC 800M base unit; maintain clearances for airflow and service access. |

Application Fields

This controller shows up a lot in process industries where uptime and predictable performance matter:

- Oil & Gas: separator trains, compressor stations, utility systems

- Chemical & Petrochemical: batch units, blending skids, polymer lines

- Power & Utilities: balance-of-plant loops, water/steam cycle support

- Water & Wastewater: filtration, pumping stations, remote I/O nodes

- Pulp & Paper and Mining: drive coordination, process interlocks, environmental monitoring

One thing I appreciate is how easily it lets you re-use existing S800 I/O and field networks. In many cases, migrations end up being faster because the AC 800M ecosystem is consistent across CPUs.

Advantages & Value

- Reliability – Proven AC 800M hardware with redundancy options to keep processes running during maintenance or faults.

- Compatibility – Works with a broad set of ABB communication modules, plus widely used protocols like PROFIBUS and Modbus.

- Lifecycle cost control – Extend the life of installed S800 I/O and reduce rewiring; engineering tools remain consistent across the platform.

- Supportability – Diagnostics, firmware tools, and documentation are straightforward, which typically shortens commissioning time.

Feedback from a utilities client: “We swapped our older PM851 controllers for PM856A in a staged upgrade. Engineering files transferred smoothly, and we kept our S800 I/O untouched. Downtime was under a shift.”

Installation & Maintenance

- Cabinet & environment – Install in a clean, dry control cabinet; keep ambient 0–55 °C with adequate ventilation. Avoid direct vibration and EMI sources.

- Power & grounding – Use a stabilized 24 V DC supply (SELV/PELV), proper bonding to cabinet ground, and surge protection where required.

- Networking – Separate control Ethernet from power wiring, use shielded cables, and implement a plant time server for NTP.

- Redundancy setup – For HA applications, pair with an identical PM856A and follow ABB’s redundancy wiring and switchover guidelines.

- Routine maintenance – Periodically back up the application, verify time sync, review diagnostic logs, dust off module vents, and plan firmware updates during scheduled outages.

Quality & Certifications

- Manufacturer quality systems: ISO 9001

- Product compliance: CE; typically UL/cUL and RoHS for this family

- Warranty: 12 months (365 days)

Common Supporting Components (Optional)

- ABB CI854A – PROFIBUS DP-V1 communication interface for connecting S800 I/O over DP or third-party PROFIBUS devices.

- ABB CI871 – Modbus TCP interface for easy integration with drives, analyzers, and MCCs on Ethernet.

- S800 I/O modules – Digital and analog input/output modules with TU/TB terminal bases for local or remote expansion.

You might notice that this kit is often chosen when teams want to standardize on the AC 800M platform across units. It seems to be the practical choice when you want redundancy readiness without the footprint or cost of the top-tier CPUs.

Reviews

There are no reviews yet.