Description

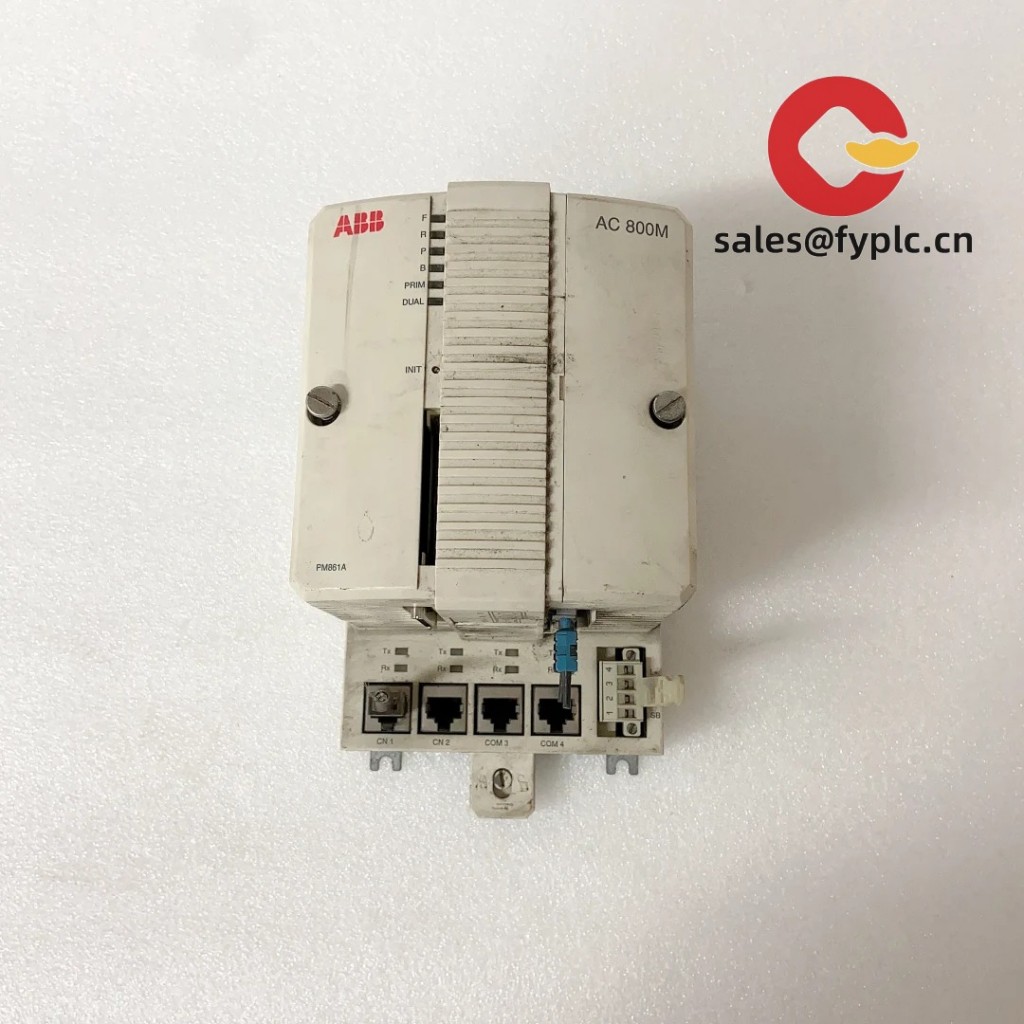

ABB PM861K01 (3BSE018105R1) – AC 800M CPU module for 800xA process control

The ABB PM861K01 is a proven AC 800M processor module widely used in ABB 800xA systems. From my experience, plants choose the PM861 when they need solid, deterministic control without overspecifying hardware. It slots into the standard AC 800M base unit, connects to S800 I/O through communication interfaces, and typically runs seamlessly in existing 800xA architectures. You might notice that it’s often specified as a long-term spare because it balances availability, performance, and compatibility with installed assets.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- AC 800M controller platform: Designed for ABB 800xA, with predictable cyclic execution for process applications.

- Dual 10/100 Ethernet: Typically used for plant and service networks, simplifying diagnostics and engineering access.

- CEX-bus expansion: Works with communication modules to connect S800 I/O and field networks (e.g., Profibus DP or Modbus via options).

- High availability options: Supports redundant controller configurations for critical processes when paired with the appropriate accessories.

- CompactFlash program storage: Non-volatile storage for application and firmware; easy to replace during maintenance.

- Online engineering in many cases: Supports online configuration changes within the 800xA/Control Builder environment when procedures are followed.

- Installed base friendly: Backward-compatible approach reduces change management and downtime during upgrades or replacements.

Technical Specifications

| Brand / Model | ABB PM861K01 – 3BSE018105R1 (AC 800M CPU module) |

| Series | AC 800M / 800xA |

| HS Code | 8538.90 (Parts for industrial control apparatus) |

| Power Requirements | 24 VDC supplied via AC 800M base unit (typical low-power CPU consumption) |

| Operating Temperature | Typically 0 to +55 °C (non-condensing environment) |

| Communication Interfaces | 2 × Ethernet 10/100Base‑T, 1 × service/serial (CPU-level); CEX‑bus for expansion modules |

| Signal I/O Types | No onboard I/O; interfaces to S800 I/O via communication modules (e.g., Profibus DP, Modbus—depending on option) |

| Installation Method | Mounted on AC 800M base unit; DIN‑rail cabinet installation |

| Program Storage | CompactFlash (firmware and application) |

Application Fields

The PM861K01 is typically deployed in continuous and batch process units where stable, deterministic control matters more than raw CPU speed. I’ve seen it run reliably in:

- Oil & gas production skids, compressor stations, and pipeline auxiliaries

- Water and wastewater treatment (filtration trains, pump stations, clarifiers)

- Pulp & paper stock prep, DCS islands, and finishing sections

- Conventional and renewable power balance-of-plant

- Metals & mining utilities, conveying, and crushing circuits

- Marine auxiliary systems and engine room controls (where 800xA is present)

One thing I appreciate is how easily it ties into S800 I/O and optional fieldbus modules, so retrofit jobs usually avoid big wiring changes. A maintenance lead at a paper mill summed it up well: “We swapped in a PM861 spare and were back in auto within the hour—no recipe loss, no drama.”

Advantages & Value

- Reliability: Mature controller hardware with predictable behavior under 800xA control; good track record in 24/7 duty.

- Compatibility: Works with existing AC 800M bases, S800 I/O, and common communication options—reducing re-engineering risk.

- Lifecycle cost: Reuse of I/O and networks typically lowers project cost; spares strategy is straightforward.

- Support: Broad industry adoption means easier access to expertise, documentation, and firmware packages.

Installation & Maintenance

- Cabinet & power: Install on the AC 800M base unit in a ventilated enclosure; 24 VDC power with proper grounding. Keep ambient within the stated operating range.

- Networking: Use shielded CAT5e/6 for the dual Ethernet ports; segregate control and service networks where possible.

- I/O & buses: Add communication modules on the CEX‑bus for field networks (e.g., Profibus DP or Modbus). Follow ABB grounding and shielding practices to minimize noise.

- Safety: De‑energize before inserting/removing modules unless the redundancy procedure specifically allows otherwise. Observe ESD handling.

- Routine care: Periodically back up the CompactFlash; align controller firmware with 800xA/Control Builder versions; clean connectors and check ventilation filters during planned shutdowns.

Typical Companion Modules (for planning)

- AC 800M base units (DIN‑rail) and 24 VDC power units

- Communication modules via CEX‑bus, such as Profibus DP or Modbus TCP/RTU interfaces (model selection depends on your field devices)

- S800 I/O modules and terminals for process signals

- Redundancy and time-sync accessories for high-availability architectures

Quality & Certifications

- Conforms to major industrial standards; typically CE and UL/cUL marked

- RoHS compliant manufacturing in most cases; ISO 9001 quality systems

- Seller warranty: 365 days from delivery; units are function-tested before dispatch

Reviews

There are no reviews yet.