Description

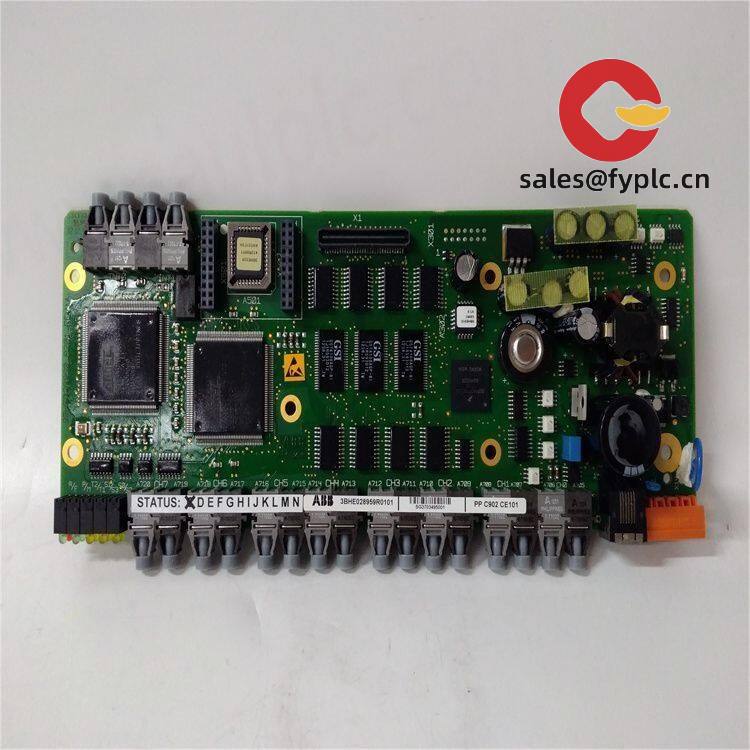

ABB PPC902CE101 (3BHE028959R0101) – High‑speed controller board for AC 800PEC real-time control

The ABB PPC902CE101, part number 3BHE028959R0101, is a processor board used in the AC 800PEC platform. From my experience, this is the heart of many ABB power electronics applications—where deterministic control, fast cycle times, and tight synchronization really matter. If you’re maintaining PEC-based drives or converter systems, this unit serves as a reliable drop‑in replacement that typically restores performance without reworking your field wiring.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Real-time control core: Designed for AC 800PEC to handle fast loop control in drives, converters, and high‑speed process applications.

- Deterministic performance: Typically supports very short control cycles, which helps stabilize demanding power electronics processes.

- Robust platform compatibility: Drop‑in replacement for existing AC 800PEC assemblies, minimizing downtime and engineering changes.

- Industrial networking: Ethernet-based service/plant connectivity; service access for commissioning and diagnostics in most cases.

- Backplane integration: Interfaces to PEC I/O over the controller backplane—no need to rewire field devices when replacing the CPU board.

- Serviceability: You might notice that firmware and application images can be managed in a predictable way, easing version control and rollback procedures.

Technical Specifications

| Brand / Model | ABB PPC902CE101 (Part No. 3BHE028959R0101) |

| HS Code | 8537.10 (Programmable controllers) |

| Power Requirements | Powered via AC 800PEC backplane; controller supply typically 24 VDC (nominal) |

| Operating Temperature | Typically 0 to +55 °C in a ventilated industrial cabinet |

| Signal I/O Types | Backplane interface to PEC I/O and converter boards; no direct field I/O on the CPU board |

| Communication Interfaces | Ethernet (service/plant), service/maintenance port; additional links depend on AC 800PEC assembly |

| Installation Method | Plug‑in controller board for AC 800PEC; cabinet mounting via the AC 800PEC chassis |

| Firmware / Software | Compatible with AC 800PEC engineering environment; match firmware bundle to project version |

Application Fields

The PPC902CE101 is typically used where ultra-fast, deterministic control is needed:

- Medium/low voltage drives and power converters

- Metals rolling mills, test benches, and high-dynamic motion systems

- Wind and renewable converter platforms

- Marine propulsion and industrial power quality systems

- Custom power electronics R&D setups based on AC 800PEC

Advantages & Value

- Reduced downtime: Direct replacement in existing AC 800PEC racks helps you recover production quickly.

- Compatibility confidence: Seems to be widely used across multiple PEC generations, easing lifecycle management.

- Stable performance: Real-time behavior supports tight process tolerances and consistent product quality.

- Lower integration risk: No field rewiring since I/O stays on the existing PEC interface boards.

- Service and support: In many cases we can assist with firmware matching and pre‑shipment checks.

Installation & Maintenance

- Cabinet & environment: Install in a clean, ventilated cabinet. Keep ambient within 0–55 °C and avoid condensation.

- Power & grounding: Ensure stable 24 VDC supply on the AC 800PEC chassis and maintain proper protective earth.

- ESD handling: Treat the board as an ESD‑sensitive device; use grounded wrist straps and antistatic packaging.

- Firmware alignment: Match controller firmware with your application project version; back up images before swap‑out.

- Wiring checks: Verify backplane connectors are fully seated; inspect for bent pins or debris before power‑up.

- Routine maintenance: Periodically clean dust from the cabinet filters, check connector tightness, and review diagnostic logs. Firmware updates should be validated in a test environment first.

Quality & Certifications

- CE compliant industrial control equipment

- RoHS compliant according to typical ABB hardware standards

- UL/cUL usage common for ABB control components (verify per system BOM)

- Manufacturer quality system: ISO 9001 (ABB)

- Warranty: 12 months from delivery

Related Components (for planning)

- AC 800PEC chassis and backplane

- 24 VDC power supply module for AC 800PEC

- PEC I/O and fiber/trigger interface boards as required by the application

- Engineering tools and firmware packages matched to your project version

Reviews

There are no reviews yet.