Description

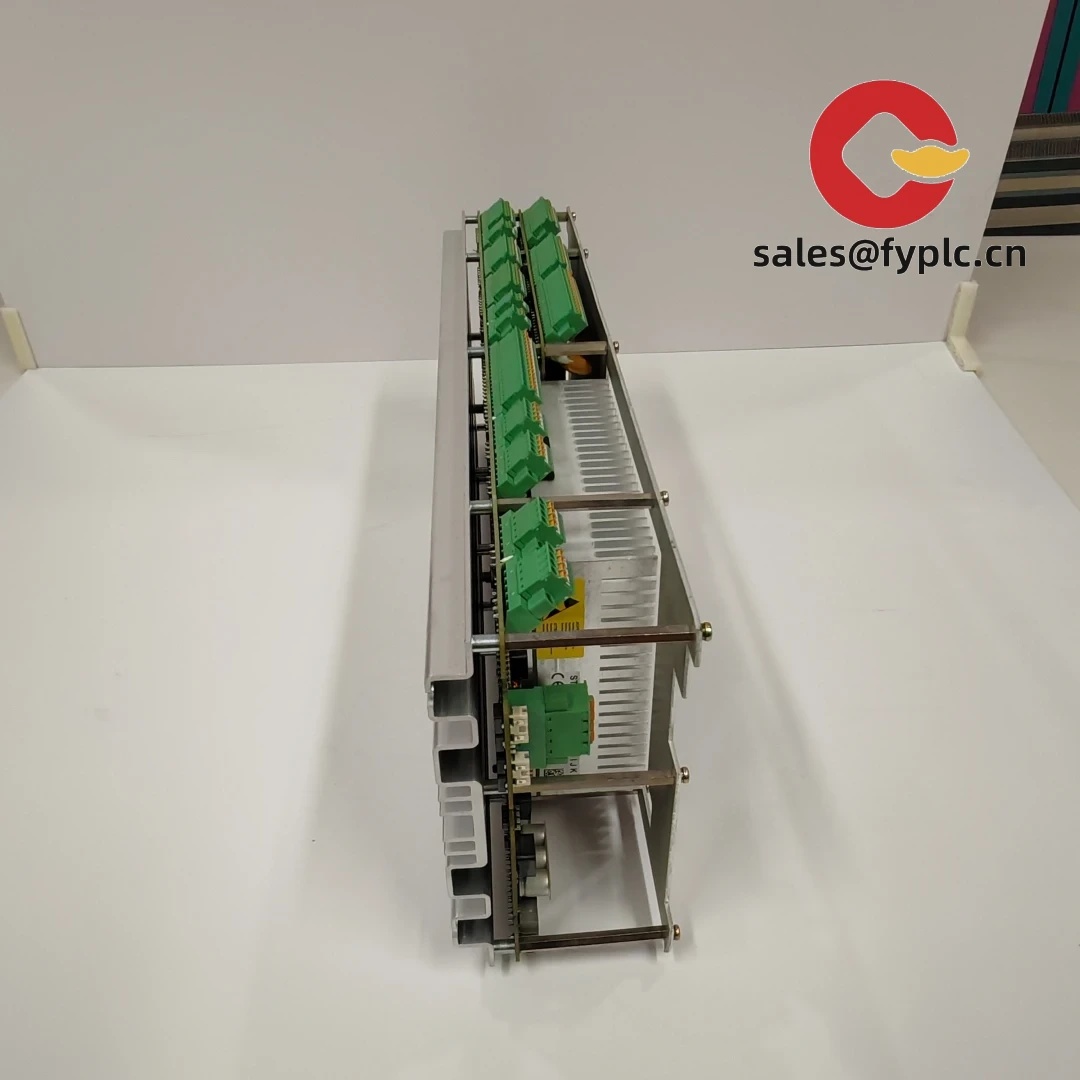

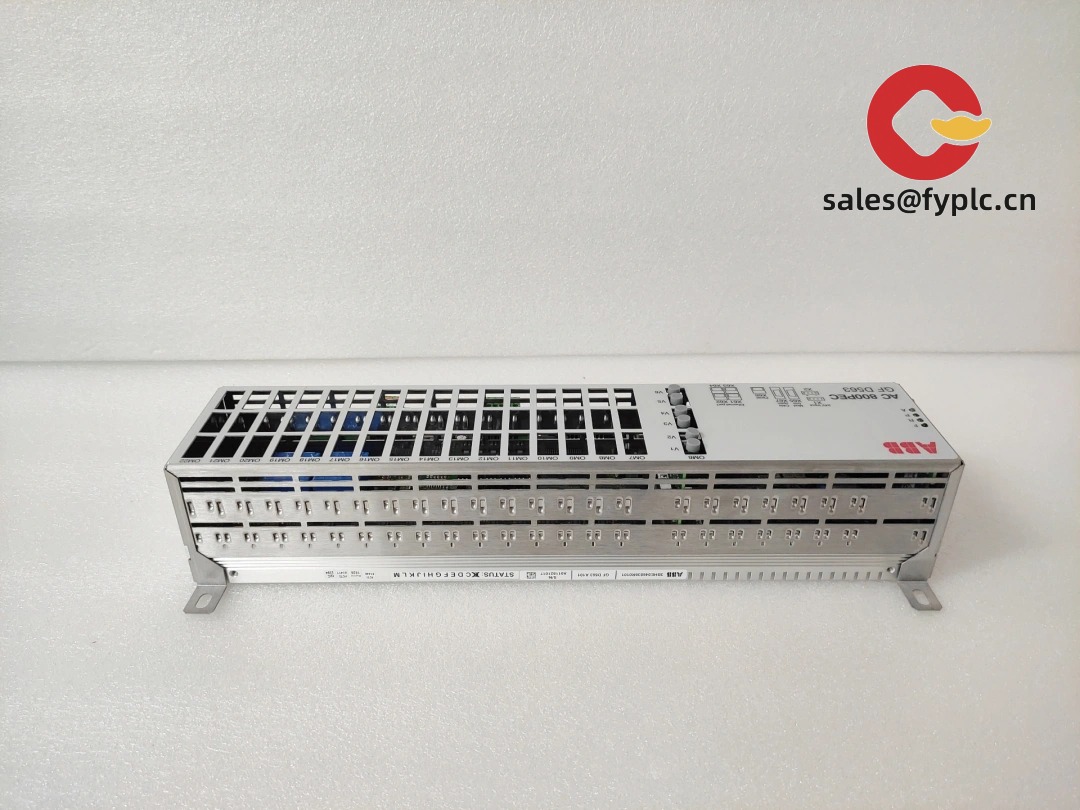

ABB PPD113B01-10-100000 – Control Board for ABB Industrial Drive and Automation Systems

The ABB PPD113B01-10-100000 is a factory-grade control board used in ABB drive and automation cabinets, typically handling internal signal processing, interlocks, and communications over the system backplane. From my experience, sites use this module as a drop-in replacement to restore stability in legacy ABB installations without reengineering the entire rack. You might notice that the “B01-10-100000” build code helps identify hardware/firmware compatibility inside specific ABB systems, which is useful when matching spares to installed bases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- Backplane-integrated design: Plugs into the ABB system rack to manage internal signals and coordination logic—no external terminal blocks in most cases.

- Industrial build quality: Robust PCB, typically conformal-coated for cabinet environments with dust and humidity variations.

- Stable power domain: Nominal 24 VDC backplane feed (common in ABB cabinets), designed for clean startup and predictable watchdog behavior.

- On-board diagnostics: Status LEDs and fault indicators simplify first-line troubleshooting and reduce MTTR on-site.

- Lifecycle-friendly: Revision traceability (e.g., B01-10-100000) helps align firmware baselines and maintain fleet consistency.

- Serviceability: Field-replaceable with ESD-safe procedures; no cabinet rework needed for like-for-like swaps.

- Compatibility focus: Designed for ABB drive/automation architectures where PPD113-series boards are specified.

Technical Specifications

| Brand / Model | ABB PPD113B01-10-100000 |

| HS Code | 8537.10 (Control panels/boards for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal via system backplane (common ABB cabinet supply; low-watt draw typical) |

| Operating Temperature | 0 to +55 °C (cabinet-mounted; non-condensing environment, typical for ABB control boards) |

| Signal I/O Types | Internal backplane I/O; handles digital/analog and interlock signals within the rack (no front screw terminals in most cases) |

| Communication Interfaces | System backplane bus; service access typically via the cabinet/host controller (interface depends on installed system) |

| Installation Method | Plug-in board for ABB rack/backplane inside a control cabinet; tool-less latch or screw-secured, ESD-safe handling |

Application Fields

This module is commonly found in ABB drive and DCS cabinets across heavy industry. Typical deployments include steel rolling lines, pulp & paper machines, mining conveyors and hoists, oil & gas process units, power generation balance-of-plant, and large HVAC/utility drives. One maintenance lead at a cement plant told us the PPD113B01 swap cleared an intermittent trip that had been causing weekend callouts—no PLC logic changes needed.

Advantages & Value for Procurement

- Drop-in continuity: Keeps the installed ABB architecture intact—no re-wiring or requalification in most cases.

- Reliability gains: Fresh board with clean connectors and updated revision helps reduce nuisance trips and intermittent faults.

- Controlled lifecycle cost: Extends asset life at a fraction of a full retrofit; faster ROI versus system migration.

- Lead time you can plan on: In-stock units typically ship in one week; we cap the wait at one month.

- Support readiness: We assist with cross-checking revisions and backplane compatibility to avoid mismatch and downtime.

Installation & Maintenance

- Environment: Install inside a sealed control cabinet with adequate ventilation; maintain ambient 0–55 °C, non-condensing.

- Power-down and ESD: Fully isolate cabinet power and follow ESD precautions (wrist strap, antistatic mat) before handling.

- Rack seating: Inspect backplane connectors; insert the board evenly until fully latched. Do not force—misalignment can damage pins.

- Firmware/parameters: Where applicable, align firmware with the site standard and back up parameters prior to replacement.

- Routine care: Quarterly cabinet dust removal (dry air, low pressure), connector visual checks, and event log review through the host system.

- Spares strategy: Keep one tested spare on site for critical lines; label with firmware/revision to match the fleet.

Quality & Certifications

- Compliance: CE and RoHS compliant in most cases for ABB control electronics.

- Manufacturing system: Produced under ISO 9001 quality management standards.

- Safety: UL recognition may apply at component level depending on cabinet/system; consult your site standard.

- Warranty: 12 months (365 days) from delivery.

Commonly Paired Components

While the PPD113B01-10-100000 is the core control board, many sites keep supporting parts on hand for faster recovery:

- ABB system backplane/rack: Ensures reliable connector mating when the existing rack shows wear or oxidation.

- 24 VDC cabinet power supply (industrial grade): Stable DC feed reduces brownout-related controller resets.

- Shielded cabinet harnesses: Replacement ribbon/backplane cables to eliminate intermittent contact issues.

- Cooling/filtration consumables: Filters and cabinet fans to maintain clean airflow and component life.

Reviews

There are no reviews yet.