Description

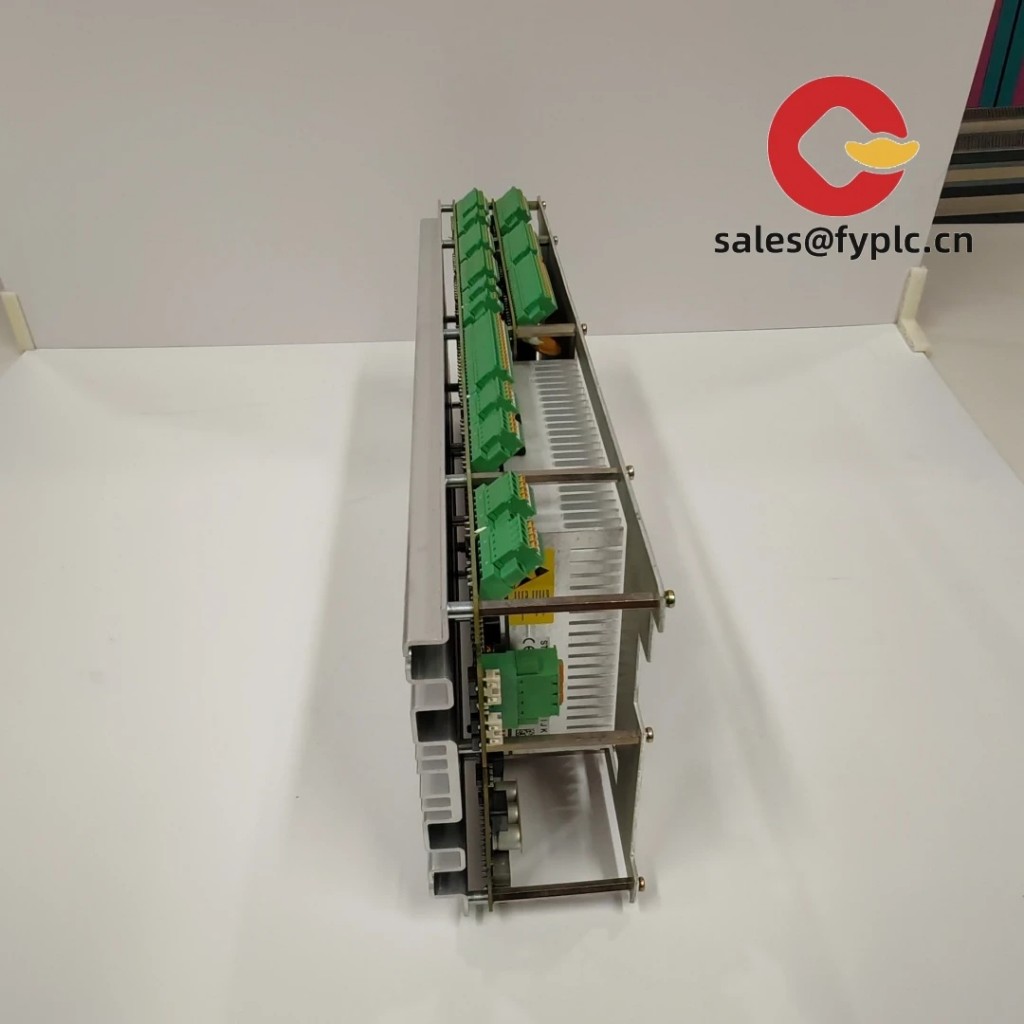

ABB PPD113B01-20-111000 – Rack I/O Signal Interface Module for ABB Control Systems

The ABB PPD113B01-20-111000 is a plug-in I/O interface module designed for ABB rack-based control systems, typically used in turbine, process, and balance-of-plant applications. From my experience, this module is favored in brownfield upgrades because it fits existing ABB backplanes without reworking the cabinet, yet still delivers stable, isolated signal conditioning for critical interlocks and machine protection. You might notice that the -20-111000 coding denotes a specific hardware/firmware option set, ensuring consistent behavior across a fleet.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Rack plug-in design: Installs directly into ABB system backplanes for quick swap and minimal downtime.

- Galvanic isolation: Isolated channels help reduce plant noise and ground loops, which in many cases improves signal stability.

- Deterministic I/O handling: Designed for predictable response in protection and interlock chains.

- Front diagnostics: Status indicators (where fitted) make it easier to troubleshoot during commissioning.

- Lifecycle-friendly: Suited for maintaining legacy ABB racks while keeping field wiring and logic unchanged.

Technical Specifications

| Brand / Model | ABB PPD113B01-20-111000 |

| HS Code | 8538.90 (Parts for electrical control equipment; final classification may vary by country) |

| Power Requirements | Supplied via system backplane; typically 24 VDC nominal from rack power supply |

| Operating Temperature | 0 to +55 °C (typical for this series; check installed system limits) |

| Signal I/O Types | Field signal interface via front terminals; isolated channels; specific channel types per -20-111000 option set |

| Communication Interfaces | System backplane bus; no external network port on the module front (typical) |

| Installation Method | Plug-in rack card for ABB control cabinets; front extraction handle and coded slotting (where applicable) |

| Form Factor | Rack module, Eurocard-style footprint (approx. 3U x 160 mm); weight typically ~0.35 kg |

Application Fields

Commonly deployed in:

- Steam and gas turbine control racks (trip logic, permissives, overspeed protection interfacing)

- Process control DCS/ESD cabinets in chemical, power, and oil & gas plants

- Balance-of-plant I/O expansion where reliable signal isolation is required

- Modernizations of legacy ABB cabinets where wiring continuity and footprint compatibility matter

One thing I appreciate is how it helps keep field wiring untouched during phased upgrades. A maintenance lead at a combined-cycle site told us they swapped a PPD113B01 during a planned outage and immediately reduced nuisance trips linked to noise on long cable runs.

Advantages & Value

- Reliability: Industrial-grade isolation and stable operation in electrical rooms subjected to EMI.

- Compatibility: Designed for ABB racks—keeps logic, marshalling, and backplane topology consistent.

- Cost Control: Typically a like-for-like replacement, reducing engineering hours and re-commissioning costs.

- Technical Support: We can help match the -20-111000 variant to your existing BOM, minimizing version risks.

Installation & Maintenance

- Cabinet & environment: Install in a clean, ventilated control cabinet; maintain ambient 0–55 °C and avoid condensation.

- Wiring practice: Separate high-voltage and low-level signal wiring; keep shield terminations consistent with site standards.

- ESD handling: Use antistatic wrist straps and handle the PCB by edges only.

- Seating & coding: Verify slot coding and ensure the card is fully seated in the backplane before powering.

- Routine checks: Inspect connectors annually; clean contacts carefully; run I/O loop tests after shutdowns.

- Firmware/configuration: Where applicable, align module revision to system configuration backups and maintain version records.

Quality & Certifications

- Manufacturing typically aligned with ISO 9001 quality systems

- CE compliance and RoHS considerations for most ABB control modules

- UL/CSA recognition may apply depending on production batch and region

- Manufacturer warranty support standard; add-on service coverage available on request

If you can share your installed base details (system type, rack slot, and current module label), we’ll verify the exact -20-111000 compatibility and propose a delivery slot that fits your outage window.

Reviews

There are no reviews yet.