Description

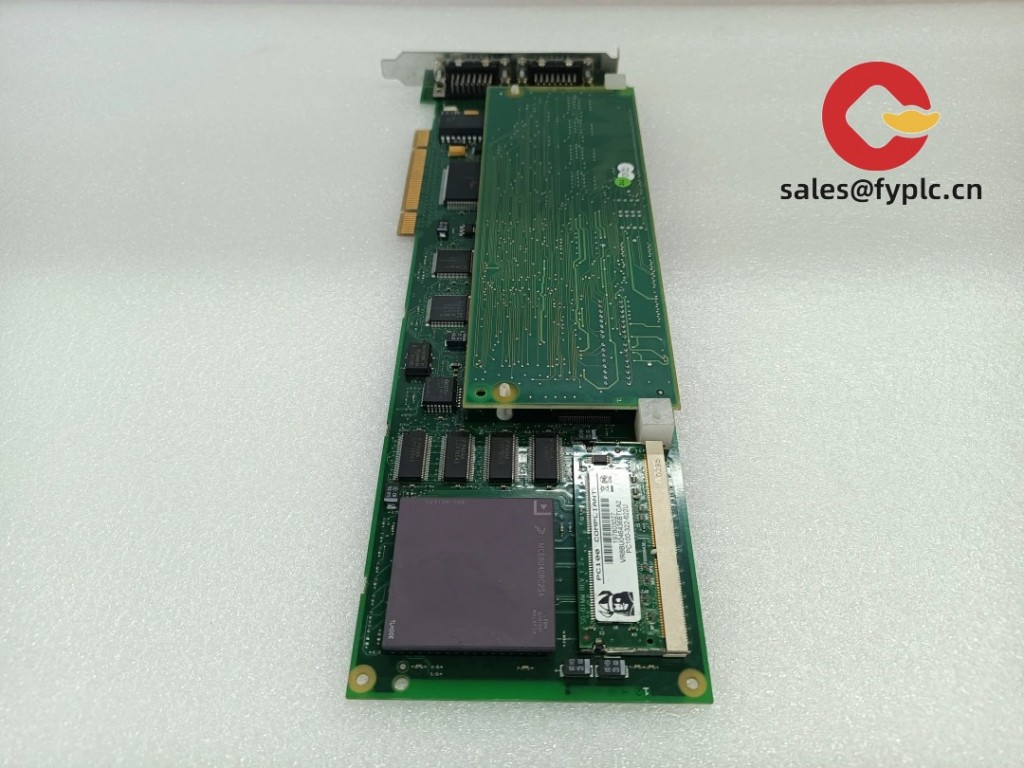

ABB S-113H 3BHB018008R0003 – Gate Driver Board for ABB Industrial Drive Inverter Stacks

The ABB S-113H (3BHB018008R0003) is a gate driver board typically used inside ABB low-voltage industrial drive inverter units to drive IGBT phase modules and interface fiber-optic control signals with the power stage. In many cases it’s deployed as a form-fit-function spare in ABB drive systems to shorten downtime and restore inverter reliability without re-engineering the cabinet.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- IGBT gate drive control – Designed to switch and protect IGBT modules within ABB inverter phases, helping maintain clean gate signals under demanding loads.

- Fiber‑optic interfacing – Uses optical links (within the drive) for noise-immune trigger and feedback paths, which is especially helpful in high-EMI motor rooms.

- Form-fit replacement – Matches the original board layout and connectors, so swap-outs are typically quick and do not require cabinet modification.

- Integrated protection logic – Supports fault feedback to the control unit to protect the power stage in the event of overcurrent or desaturation (behavior depends on drive configuration).

- Service-friendly design – From my experience, fiber ports and board standoffs are straightforward to access, which reduces troubleshooting time during shutdowns.

Technical Specifications

| Brand / Model | ABB S-113H / 3BHB018008R0003 |

| Product Type | IGBT gate driver board for inverter phase modules |

| HS Code | 8504.90 (Parts suitable for static converters) |

| Power Requirements | Supplied by the host drive’s auxiliary LV supply; typically 24 VDC, a few watts |

| Operating Temperature | Typically 0…+55 °C when installed inside a drive cabinet (follow system manual for limits) |

| Signal I/O Types | Fiber‑optic control links; gate drive outputs to IGBT modules; fault/status feedback to control unit |

| Communication Interfaces | Proprietary optical links used within ABB drive systems |

| Installation Method | Direct-mount on inverter/heatsink assembly using standoffs; plug‑in power and fiber connectors |

| Typical Compatibility | Used in ABB industrial drive inverter units (e.g., selected ABB ACS-series frames); verify by drive type code and frame size |

Application Fields

You’ll usually find the S-113H inside ABB AC drive systems running heavy-duty motors. Typical scenarios include:

- Metals and rolling mills – precise torque control under fluctuating loads

- Pulp & paper – stable inverter operation on continuous-process lines

- Oil & gas and petrochemical – pumps, compressors, and fan drives where uptime is critical

- Mining and aggregates – conveyors and hoists with high shock loads

- Marine and port equipment – winches and propulsion auxiliaries

One maintenance lead told us they swapped an S‑series gate driver in about 30 minutes during a planned stop—fiber links were re-seated, phase checks performed, and the line restarted without re-parameterization. That seems to be the norm when the drive firmware and frame are already matched.

Advantages & Value

- Reliability – Purpose-built by ABB for their inverter topology; supports stable switching and protection behavior.

- Compatibility – Form, fit, and connector layout align with ABB drive assemblies, reducing retrofit risk.

- Cost & downtime savings – Quick board replacement typically restores the inverter without replacing the full power module.

- Technical support – We assist with part identification (type code, frame) and provide handling/installation guidance.

Installation & Maintenance

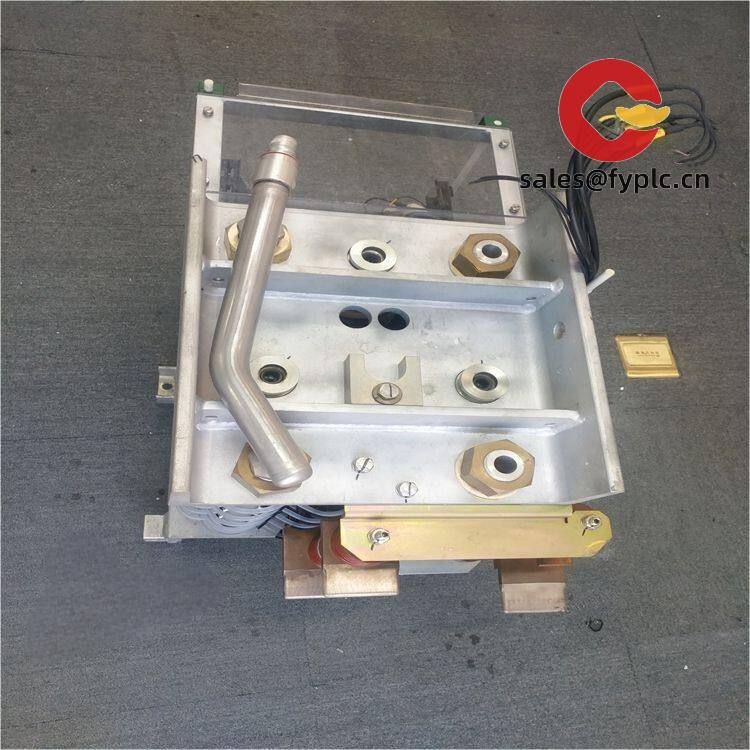

- Follow ESD precautions, isolate mains, and wait for DC link discharge before touching the inverter stack.

- Match fiber‑optic TX/RX channels exactly as labeled; you might notice channel markers on both the control unit and the gate board.

- Inspect IGBT power module terminals and busbars; tighten to manufacturer torque and confirm creepage distances are clean and dry.

- Ensure cabinet ventilation is unobstructed; dust buildup on heatsinks can mask intermittent gate faults.

- Routine: visual inspection each quarter, connector reseat if needed, and firmware/config checks on the host control unit as per the drive manual.

Quality & Certifications

- Typically part of CE/UL-compliant ABB drive systems

- Manufactured under ISO 9001 quality systems (ABB production)

- RoHS conformity for electronic assemblies, where applicable

- Warranty: 365 days

Related/Supporting Components

To complete a service event, teams often check or replace adjacent parts at the same time:

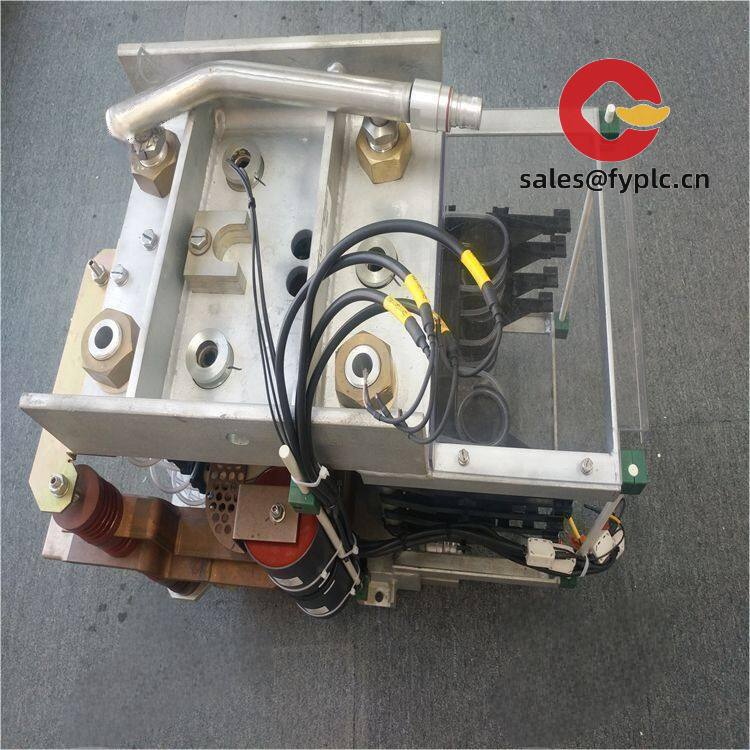

- ABB inverter phase (IGBT) power module and heatsink assembly

- Optical fiber links between control unit and gate driver

- Drive control board and interface modules (depending on the specific ABB drive family)

- Cooling fans and thermal sensors in the inverter section

If you share your drive type code and frame size, we can double‑check S‑113H 3BHB018008R0003 fitment and advise on any revision compatibility considerations. One thing I appreciate is how predictable these swaps are when the part number and frame match—the commissioning usually stays routine.

Reviews

There are no reviews yet.