Description

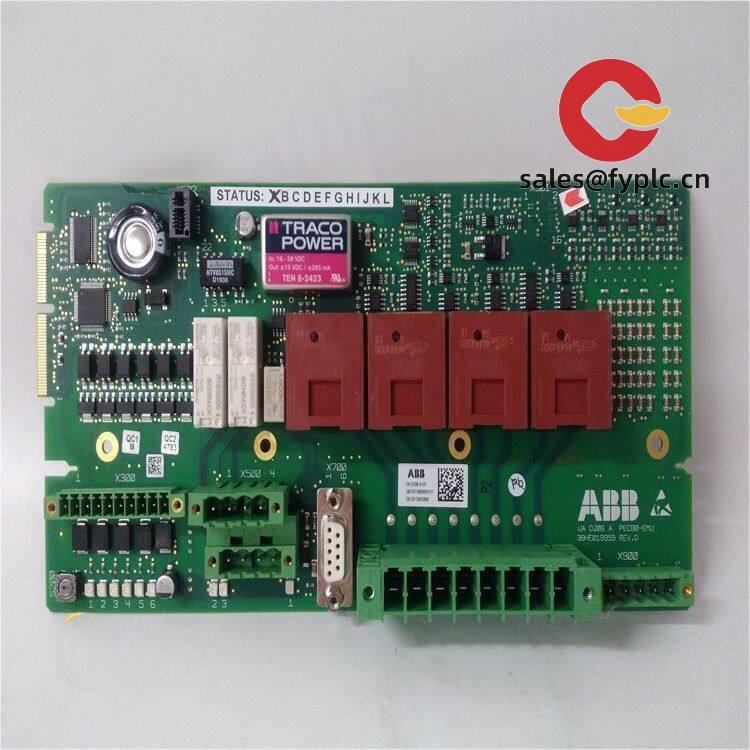

ABB SM811K01 (3BSE018173R1) – Single‑Mode Fiber CEX‑Bus Extension Module for AC 800M / S800 I/O

The ABB SM811K01, part number 3BSE018173R1, is a single‑mode fiber optic module used to extend the CEX‑bus within AC 800M and S800 I/O architectures. It’s typically paired in point‑to‑point links to bridge longer distances between controller-side communication interfaces and remote I/O clusters. From my experience, it’s a clean way to keep your cabinet count down while preserving determinism and diagnostics on the CEX bus.

One thing I appreciate is how it slots into the familiar S800 I/O form factor and runs off the backplane power—no extra power supplies in most cases. If you’re deciding between multimode and single‑mode links, this unit makes sense when you need longer runs or want tighter loss budgets across industrial sites.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Single‑mode fiber link – Suited for long runs across plants or between buildings, typically allowing multi‑kilometer CEX‑bus extension with low attenuation.

- CEX‑bus continuity – Preserves the AC 800M CEX‑bus behavior and diagnostics so you can keep standard engineering and maintenance practices.

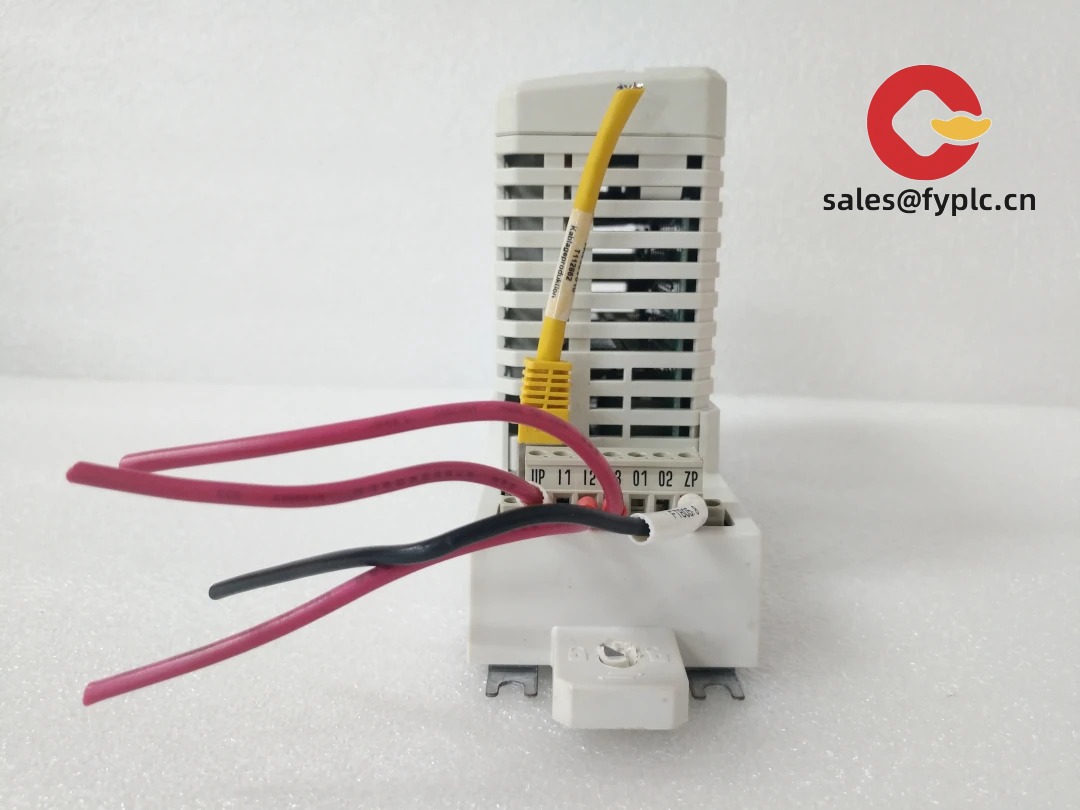

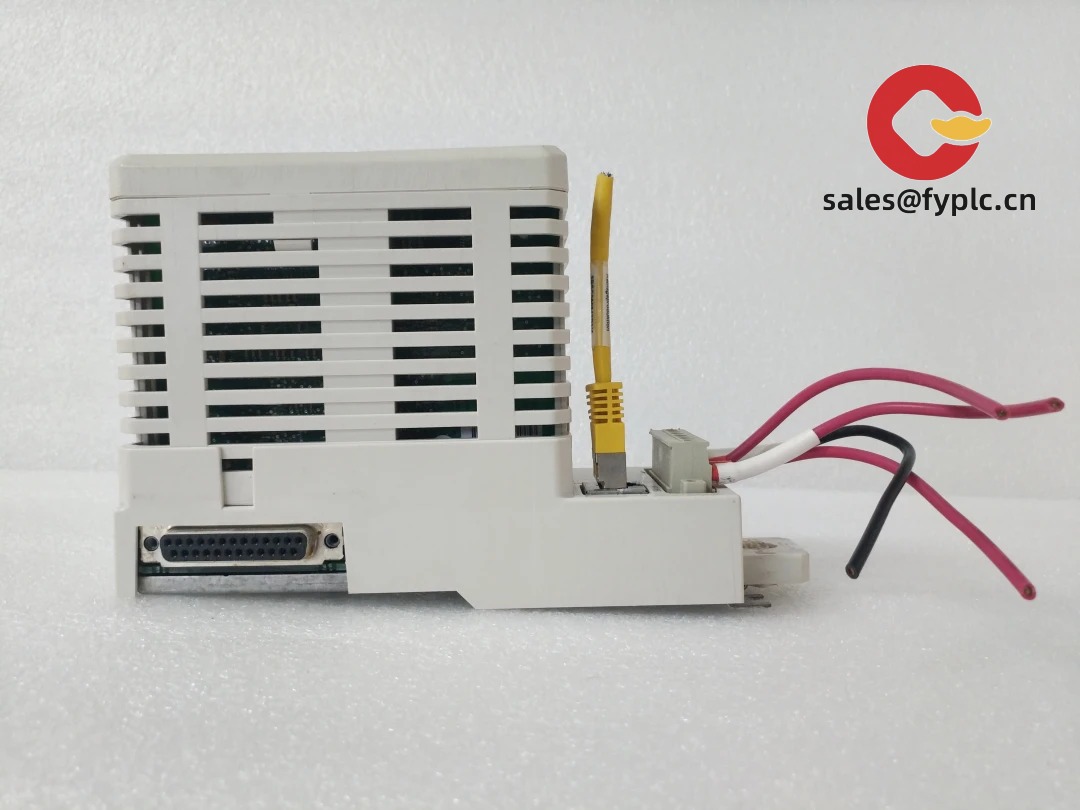

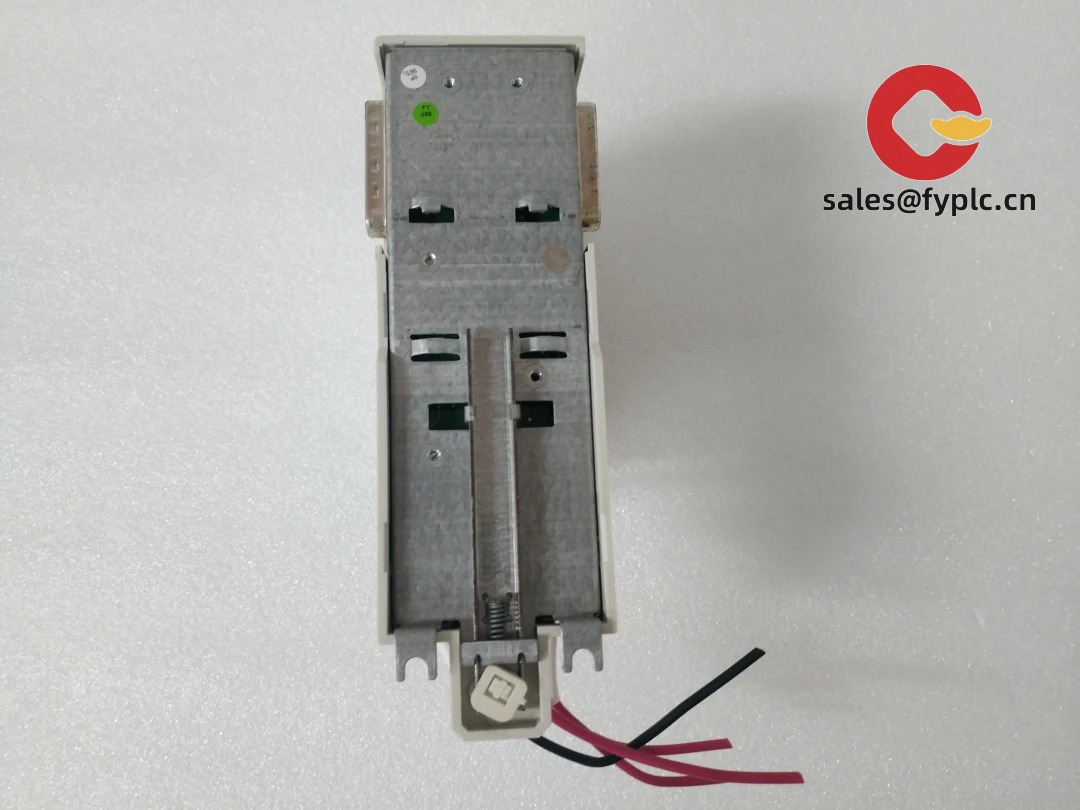

- S800 I/O form factor – Installs on the standard terminal base, simplifying cabinet layout and spares management.

- Redundant link capability – In many cases used as a paired set to provide redundant fiber paths for higher availability.

- Backplane powered – Draws 24 VDC via the base unit, reducing wiring complexity and panel components.

- Status LEDs – Quick visual checks for link and module health, which helps technicians during commissioning and routine walkdowns.

Technical Specifications

| Brand / Model | ABB SM811K01 (P/N: 3BSE018173R1) |

| HS Code | 8538.90 (Parts for switchgear/industrial control equipment) |

| Power Requirements | 24 VDC via backplane (from S800 terminal base); low power consumption, typically under a few watts |

| Dimensions & Weight | S800 I/O module size; approx. 45 mm width; compact, light module for dense cabinets |

| Operating Temperature | 0 to +55 °C (typical for S800 I/O modules) |

| Signal I/O Types | Single‑mode fiber optic CEX‑bus link (Tx/Rx); used in matched pairs |

| Communication Interfaces | CEX‑bus over fiber; supports long‑distance connectivity between AC 800M-side interfaces and remote S800 I/O |

| Installation Method | Mounts on S800 terminal base (DIN‑rail inside control cabinet); standard wiring and fiber routing practices apply |

Application Fields

This module is used where remote I/O needs to be located far from the controller or where electrical isolation is preferred:

- Process industries (chemicals, pulp & paper, food & beverage) with distributed field skids

- Power generation and utilities, especially when I/O panels span multiple buildings

- Oil & gas and petrochemical sites requiring long cable runs across hazardous or noisy areas

- Mining, metals, and water treatment where fiber helps avoid ground loops and EMI

Advantages & Value

- Reliability – Fiber links are immune to EMI and surge issues that often trouble copper in high‑power plants.

- Long distance – Single‑mode optics typically support multi‑kilometer spans, which reduces the need for intermediate panels.

- Compatibility – Designed for AC 800M / S800 I/O ecosystems; engineering and diagnostics remain consistent.

- Cost efficiency – Fewer cabinets, less copper, and easier cable routes often cut total installed cost.

- Serviceability – Clear LED states and backplane power simplify field replacement during planned shutdowns.

A maintenance supervisor told us they swapped to SM811K01 pairs on a wastewater site and “cut out two intermediate marshalling boxes, which paid for the fiber in the first phase.”

Installation & Maintenance

- Cabinet environment – Install on 35 mm DIN rail inside a ventilated control cabinet; follow typical S800 spacing to maintain airflow.

- Fiber handling – Respect minimum bend radius; keep connectors clean; use labeled, protected routes to avoid crush and strain.

- Wiring – Power is via backplane; ensure the terminal base is correctly grounded and the CEX‑bus topology is according to ABB guidance.

- Redundancy – For high availability, deploy paired modules with dual fiber paths; test failover during commissioning.

- Routine checks – Inspect link LEDs, verify fiber integrity during periodic PMs, and keep a spare module in the cabinet for quick swap.

- Safety – De‑energize and use ESD protection when inserting/removing modules; cap unused fiber ports to prevent contamination.

Quality & Certifications

- CE compliant; RoHS compliant

- Typically UL/cUL recognized for control equipment environments

- Manufacturer’s warranty: 12 months (365 days) from delivery

Related / Supporting Components

- S800 terminal bases (e.g., TB8xx series) for mounting and backplane power

- AC 800M controllers and communication interfaces (e.g., CI85x series) on the CEX‑bus

- SM810K01 multimode variant, when shorter fiber runs and multimode infrastructure are preferred

- Pre‑terminated single‑mode fiber patch cords and industrial enclosures for field routing

If you’re planning a remote I/O expansion and aren’t sure whether single‑mode or multimode is the better fit, share your cabinet distances and fiber availability. We can suggest a practical pairing strategy for the CEX‑bus that balances resilience and cost.

Reviews

There are no reviews yet.