Description

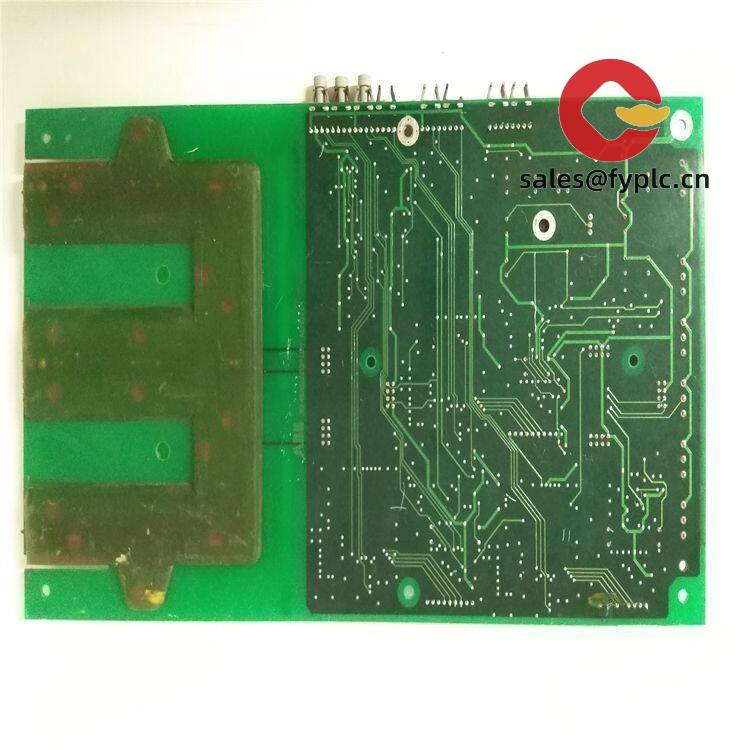

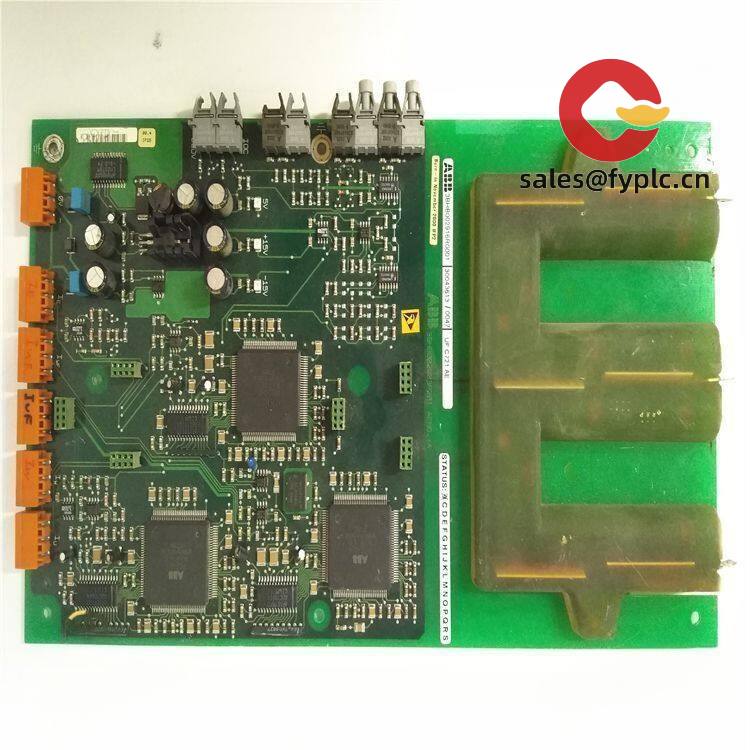

ABB UFC721AE 3BHB002916R0001 – Control Board Module for ABB Drive Systems

The ABB UFC721AE (part code 3BHB002916R0001) is a factory-grade control board used inside ABB drive and converter cabinets. From my experience, this board sits at the heart of drive control—coordinating internal signals, handling protection logic, and linking to other subsystems over ABB’s internal buses. You might notice that teams keep one on the shelf because it’s typically the fastest way to recover a downed drive during an unexpected trip.

It’s designed as a direct-replacement spare for installed ABB equipment, so no awkward mechanical changes or wiring gymnastics. In many cases, swap-in, parameter check, and a short functional test are all you need to get production moving again.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days from delivery

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- OEM spare, exact fit – Built for ABB systems using the UFC72x platform, reducing commissioning time and risk.

- Stable control and protection logic – Coordinates internal drive functions for reliable start/stop, fault handling, and interlocks.

- Backplane-powered – No external power brick; receives low-voltage power via the host drive.

- Noise-robust design – Layout and isolation practices suited to high-EMI environments found in drive cabinets.

- Status LEDs for quick checks – Visual indicators help maintenance confirm board health and communication state during troubleshooting.

- Service-friendly – Plug-in form factor with defined mounting points and connectors, simplifying field replacement.

Technical Specifications

| Brand / Model | ABB UFC721AE |

| Manufacturer Part No. | 3BHB002916R0001 |

| Product Type | Drive control board (plug-in module) |

| HS Code | 85389000 (Parts for electrical control apparatus) |

| Power Requirements | Supplied via host drive backplane (low-voltage internal rail, typically 24 VDC) |

| Operating Temperature | Typically 0 to +55°C when installed inside a compliant cabinet |

| Signal I/O Types | Internal control and feedback via dedicated connectors; user I/O handled by the host system |

| Communication Interfaces | ABB internal bus/backplane; fiber or shielded links where configured by the host system |

| Installation Method | Plug-in PCB; secured with screws/stand-offs; ESD-safe handling required |

| Dimensions & Weight | Board-level module; compact footprint suited to the designated slot in ABB cabinets |

Application Fields

This model is typically applied in ABB low- and medium-voltage drive systems across:

- Pumps, compressors, and fans in water, HVAC, and district energy plants

- Conveyors, mixers, and extruders in food, chemical, and plastics

- Rolling mills, crushers, and kilns in metals and cement

- Oil & gas rotating equipment and test stands

A maintenance lead at a cement plant told me their team swapped in a UFC721AE during a planned stop and shaved hours off restart time compared with repairing the existing board on-site. That seems to be the pattern—keep one ready to minimize downtime.

Advantages & Value

- Reduced downtime risk – Direct fit and familiar diagnostics help restore operation faster.

- Compatibility with installed base – Aligns with ABB UFC72x architecture used widely in fielded systems.

- Quality and reliability – Built for harsh electrical environments inside drive cabinets.

- Total cost perspective – In many cases, replacing the board is more economical than extended fault-finding on a failed PCB.

- Technical support – Parameter back-up and basic installation guidance available to streamline commissioning.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated enclosure. Follow ABB panel spacing and airflow guidelines.

- Power isolation – Lockout/tagout. Wait for DC link discharge before opening the cabinet.

- ESD precautions – Use a grounded wrist strap, handle by edges, avoid touching components and pins.

- Mounting – Insert straight into the designated slot; confirm connectors seat fully; secure with the correct hardware.

- Wiring – Keep fiber/shielded links with proper bend radius and grounding practices if applicable to your configuration.

- Routine care – Periodic dust removal with dry, oil-free air; check connectors for oxidation; back up parameters before any change.

- Firmware/config – Load versions recommended for your drive release; in most cases, match to the host to avoid compatibility issues.

Quality & Certifications

- CE conformity as part of the complete ABB system

- RoHS compliance in most regions

- Manufactured under ISO 9001 quality systems

- Warranty: 12 months (365 days) from delivery

Related and Supporting Components

- ABB backplane and interconnect cables for UFC72x-series slots

- Fiber-optic links used within ABB drive cabinets (where specified by the host)

- Associated I/O modules and interface cards matched to the drive type

If you’d like, share your existing drive type and firmware level, and I’ll double-check UFC721AE 3BHB002916R0001 alignment to your installed configuration. That quick step typically prevents version mismatches and repeat cabinet openings.

Reviews

There are no reviews yet.