Description

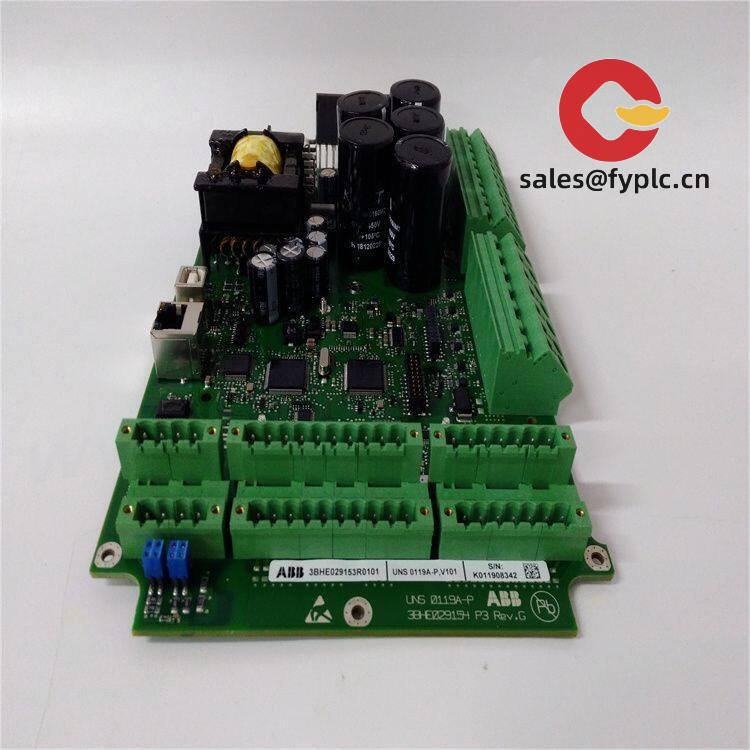

ABB UNS0119A-Z;V1 3BHE030579R0001 – Interface Module for AC 800PEC-Based Industrial Control

The ABB UNS0119A-Z;V1 (part number 3BHE030579R0001) is typically used as a plug-in interface/conditioning module within ABB AC 800PEC-based systems. From my experience, this series shows up in high-demand applications like power converters, excitation systems, and drive controls where deterministic response and robust isolation are non‑negotiable. You might notice that it’s designed as a drop-in board that integrates through the PEC backplane, keeping field wiring stable and minimizing rework during replacement.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

- Packaging: anti-static protection with shock-absorbing inner pack, sealed outer carton

- Traceability: shipment photos and serial/part number verification provided on request

Key Features

- AC 800PEC ecosystem compatibility – Engineered to operate within ABB’s PEC subrack/backplane, allowing quick swap with minimal configuration.

- Stable signal handling – In many cases used for isolated signal interfacing or conditioning between field signals and the PEC controller.

- Backplane-powered – Typically powered via the PEC backplane (24 VDC source), reducing separate wiring and failure points.

- Industrial temperature rating – Designed for cabinet installation in control rooms or MCCs with standard industrial ambient conditions.

- Service-friendly design – Plug-in form factor shortens mean time to repair; diagnostics can be performed through the host controller’s tools.

- Proven in demanding sites – Seems to be favored in applications where uptime and electromagnetic robustness matter (drives, excitation, power converters).

Technical Specifications

| Brand / Model | ABB UNS0119A-Z;V1 (3BHE030579R0001) |

| HS Code | 8538.90 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | Typically 24 VDC via AC 800PEC backplane (power consumption is application-dependent, commonly low) |

| Operating Temperature | 0 to +55 °C (non‑condensing environment, cabinet mounted) |

| Signal Input/Output Types | Interface/conditioning via PEC backplane; actual I/O presented through the host system configuration |

| Communication Interfaces | Backplane interface for AC 800PEC controller (no standalone fieldbus on the module itself in most cases) |

| Installation Method | Plug-in board for PEC subrack; seated with guide rails and locked per ABB procedure |

| Dimensions & Weight | Compact plug-in module; lightweight (typically under 0.5 kg) |

Application Fields

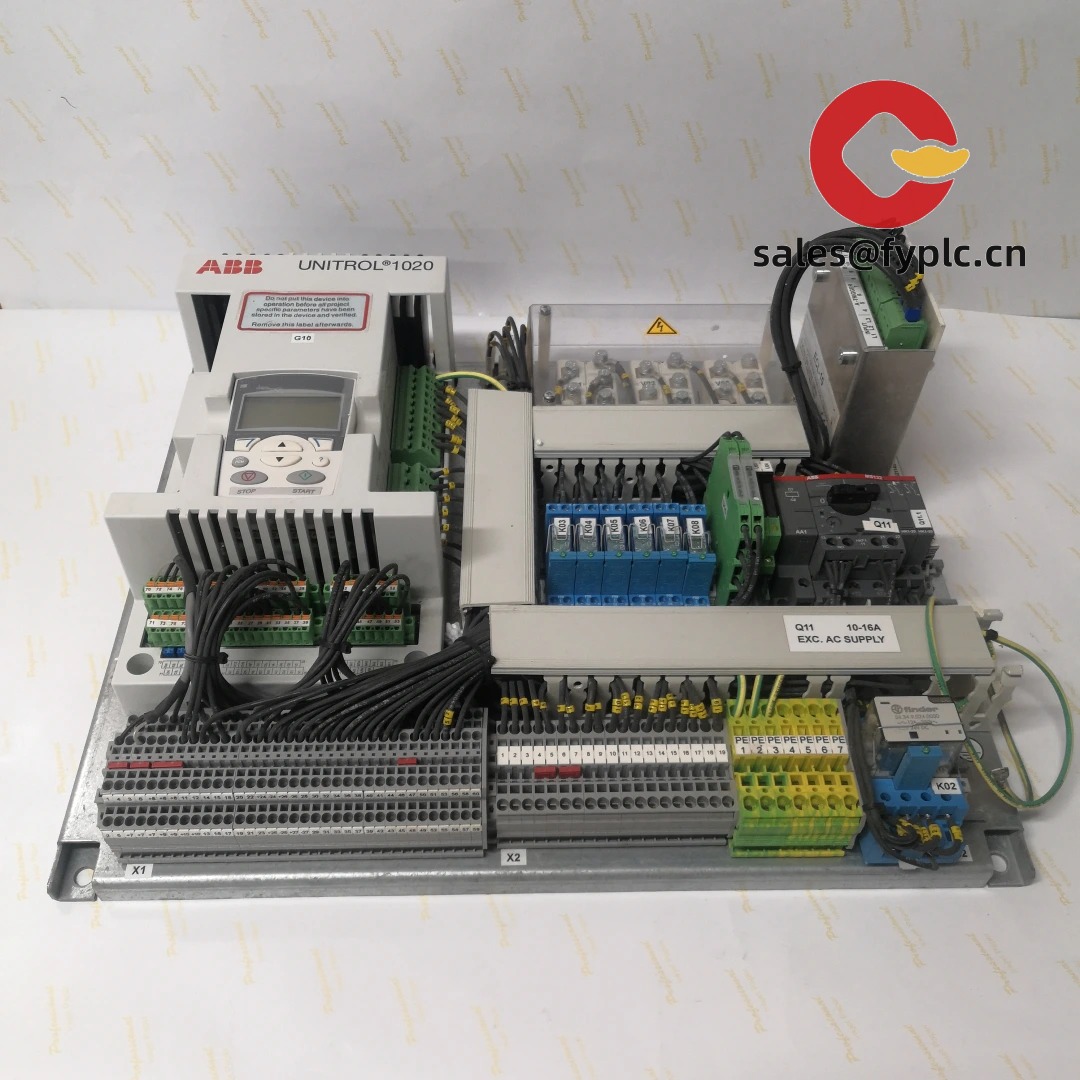

This model is commonly deployed in AC 800PEC-based solutions across:

- Medium/high-power drives and converters for metals, mining, and pulp & paper

- Generator excitation systems and synchronous motor control

- Power quality and grid applications (e.g., filters, reactive power control)

- Renewables and test benches where fast control loops are required

A maintenance lead at a steel plant told us they kept a spare UNS-series board on the shelf because it “saves a shift” when a converter trip points to the interface chain. That seems to be a common theme: quick swap, back in service, then tune during a planned stop.

Advantages & Value

- Drop-in replacement – Keeps wiring and host configuration intact, reducing downtime and commissioning effort.

- System reliability – Designed for PEC environments with solid EMC behavior and stable thermal performance.

- Lifecycle support – We verify hardware revision V1 compatibility and share handling notes before shipment.

- Total cost control – Faster recovery after a failure and less engineering time typically outweighs the purchase price.

- Traceable sourcing – Serial/part number checks and photo evidence help your QA and audit trail.

Installation & Maintenance

- Environment – Install in a closed control cabinet with adequate ventilation; keep ambient 0–55 °C, RH 5–95% non‑condensing.

- Mounting – Power down the PEC system, discharge stored energy, observe ESD precautions, slide the module along the guide rails and lock fully into the backplane connector.

- Wiring – Field wiring remains on terminal assemblies or host interfaces; confirm slot position and addressing per your project documentation.

- Safety – Only qualified personnel should install or replace; verify grounding and shield continuity to reduce noise.

- Routine care – Periodically clean dust with dry air, check cabinet fans/filters, and run controller diagnostics. Firmware or configuration updates are handled via the host PEC controller, if applicable.

Quality & Certifications

- Conforms to CE requirements for industrial environments

- RoHS compliant components and manufacturing

- Manufactured under ISO 9001 quality management systems

- Warranty: 12 months (365 days) from delivery

Reviews

There are no reviews yet.