Description

ABB UNS0119A-P;V101 (3BHE029153R0101) – Industrial Control Board for ABB Cabinet Systems and Service Spares

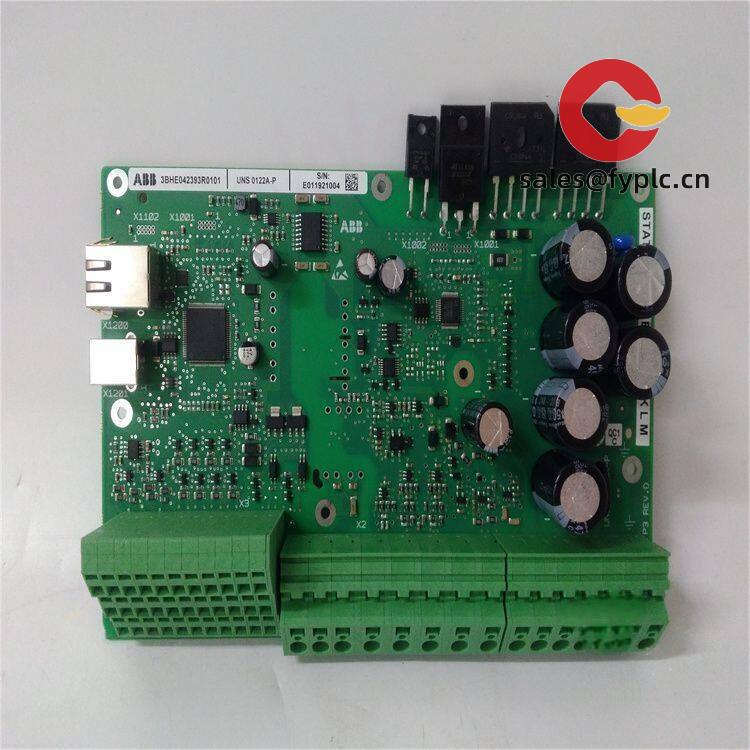

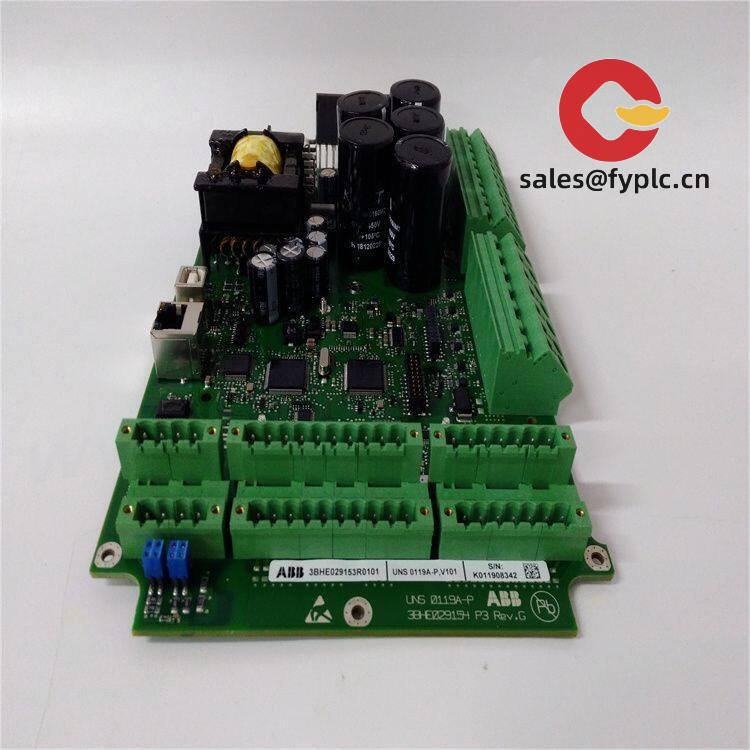

The ABB UNS0119A-P;V101, identified by part number 3BHE029153R0101, is a plug-in control/interface board used in ABB cabinet-based control and drive/excitation systems. From my experience, it’s often stocked as a like-for-like replacement to keep installed ABB assets running without re-engineering. You might notice that version “V101” indicates a specific hardware revision, which matters for drop‑in compatibility and firmware alignment.

Our Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

- Process: Confirm model/revision → Receive quotation → Place PO and prepay → Functional check and packing → Final payment → Express shipment with tracking

Key Features

- Genuine ABB spare, V101 revision – Helps ensure electrical and firmware compatibility in existing panels.

- Backplane-powered design – Typically draws power from the system rack, minimizing field wiring changes during replacement.

- Industrial-grade build – In many cases includes protective coatings and robust components suited for cabinet environments.

- Stable I/O and signal handling – Designed to interface with ABB system buses and conditioned signals with good noise immunity.

- Status indicators for fast diagnostics – You might notice front LEDs/test points that make commissioning and fault tracing quicker.

- Service-friendly form factor – Plug-in board with front-panel retention, typically swap-and-verify with minimal downtime.

Technical Specifications

| Brand / Model | ABB UNS0119A-P;V101 (3BHE029153R0101) |

| HS Code | 8538.90 (Parts for industrial control apparatus of 8537) |

| Power Requirements | Supplied via system backplane; typically 24 VDC input with on-board low-voltage regulation (system-dependent) |

| Dimensions & Weight | Plug-in PCB format suitable for ABB racks; typical weight ~0.3–0.6 kg (board assembly) |

| Operating Temperature | 0 to +55 °C (cabinet environment; non‑condensing humidity) |

| Signal I/O Types | Board-level logic/analog conditioning as per application; isolation and filtering typically provided |

| Communication Interfaces | System backplane bus; front diagnostics/connectors may be present depending on revision |

| Installation Method | Rack-mounted plug-in card; secured with front-panel screws; wiring through backplane/terminal blocks |

Application Fields

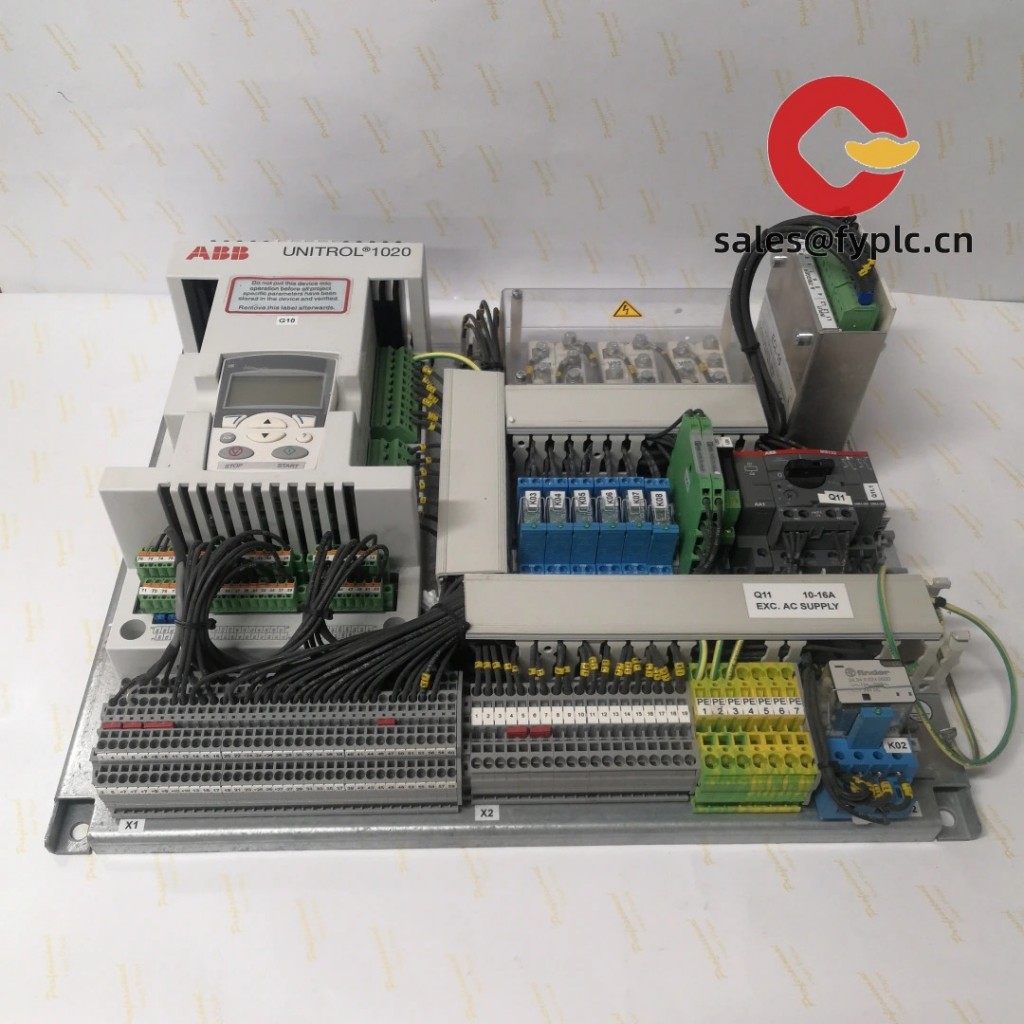

This model appears in ABB cabinet systems used across power generation, metals, mining, marine, oil & gas, and pulp & paper. Maintenance teams typically keep it as a known-good spare to restore I/O or interface functions when a card fails. One thing I appreciate is how it fits into existing racks without field rewiring, which keeps hot work and production risk low.

Advantages & Value

- Reliability in service – Designed for continuous industrial duty; stable performance in well‑ventilated cabinets.

- Compatibility – V101 revision helps match existing firmware/hardware baselines and avoids integration surprises.

- Lower downtime costs – Swap the module, verify status LEDs, and return the line to service quickly.

- Procurement confidence – Traceable part number (3BHE029153R0101) supports QA documentation and spares management.

A utilities customer told us they replaced the board during a planned 40‑minute window and avoided a full-day outage—seems to be typical when the rack and revision match.

Installation & Maintenance

- Environment – Install in a clean, closed control cabinet with adequate ventilation; avoid condensation and corrosive atmospheres.

- Wiring – Power and signals are typically via the system backplane/terminal blocks; verify connector alignment and keying before insertion.

- ESD and safety – De-energize the rack when required by site procedures; use ESD protection and avoid touching component leads.

- Commissioning – Check status LEDs, run system self-tests, and confirm firmware/revision compatibility with the host controller.

- Routine care – Periodically inspect for dust buildup, reseat connectors if needed, and keep firmware/configuration backups aligned with your system revision.

Quality & Certifications

- Manufactured for ABB industrial applications; typically used in systems conforming to CE and relevant EMC/low-voltage directives.

- RoHS compliance depends on production year and system type; documentation available on request.

- Backed by our 365‑day warranty on function and workmanship.

Need help verifying V101 compatibility with your rack or controller? Share your current board photo and system type; we’ll cross-check the revision and advise the safest drop‑in option.

Reviews

There are no reviews yet.