Description

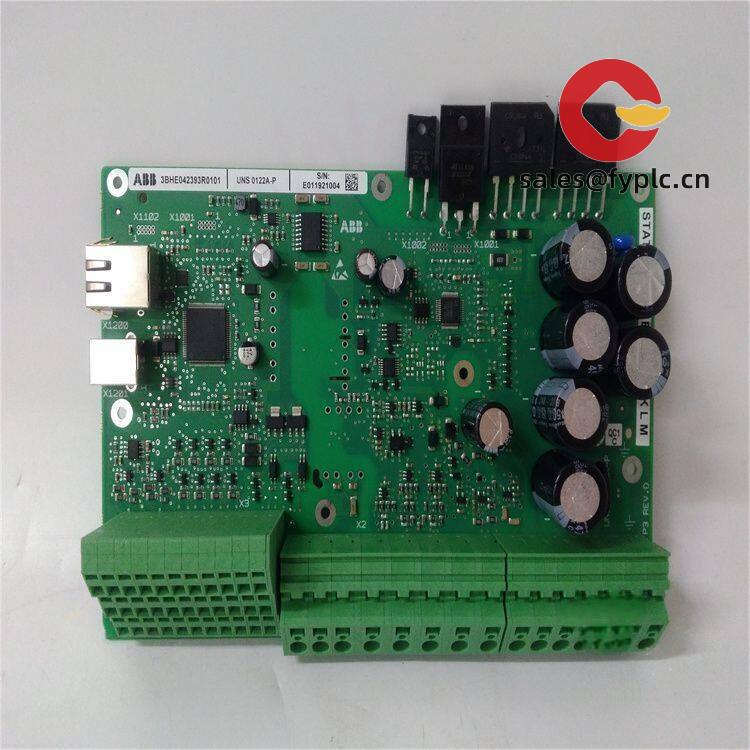

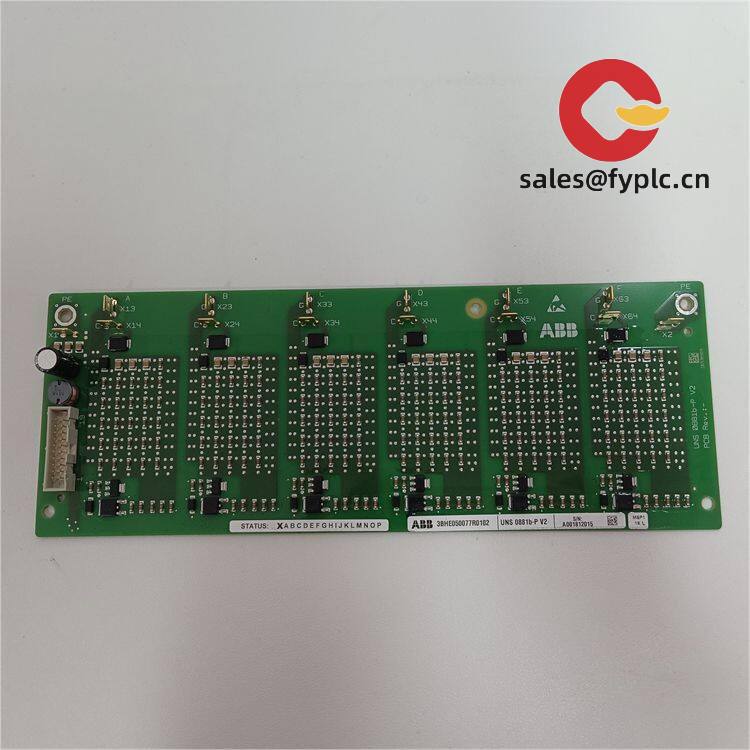

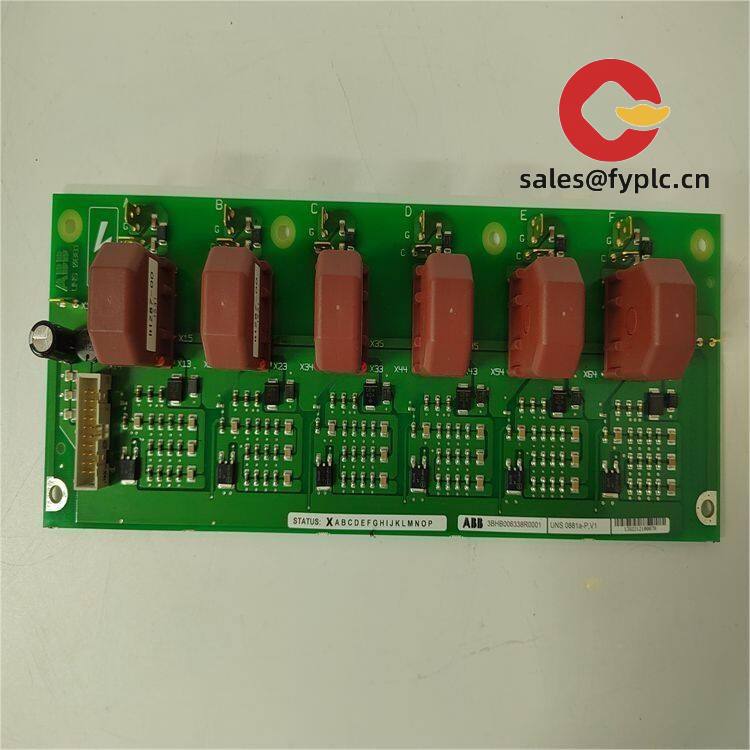

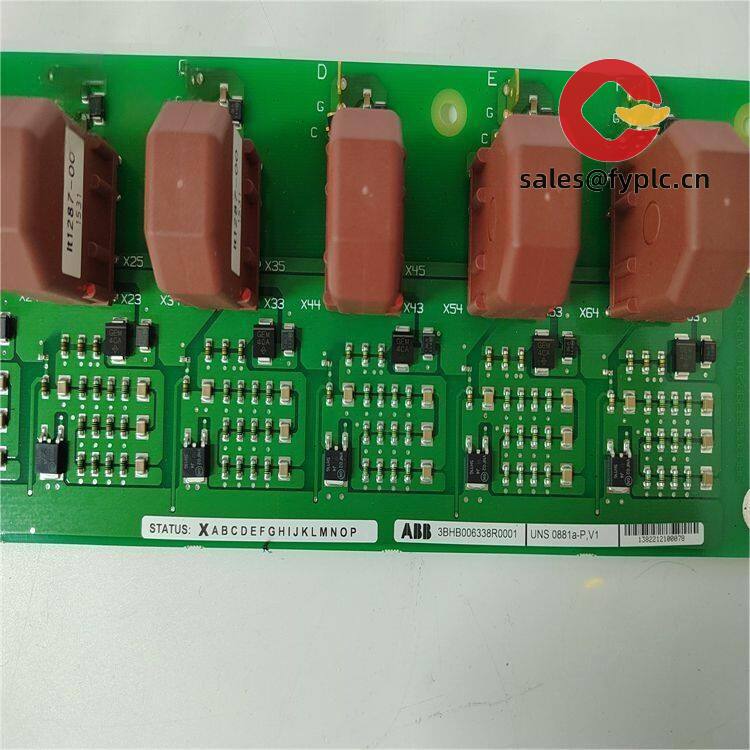

ABB UNS0881a-P;V1 (3BHB006338R0001) – Control/Interface Board for ABB Industrial Drives

The ABB UNS0881a-P;V1, order code 3BHB006338R0001, is an original ABB printed circuit board typically used inside ABB drive cabinets as part of the control and signal interface layer. From my experience, this board shows up in many installed bases of ABB variable-speed drives where reliable low-voltage control, inter-board communication, and conditioned I/O are required. If you’re planning a proactive spare strategy or a fast swap for a down line, this model seems to be one of those “keep on the shelf” items that prevents extended downtime.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Each unit is ESD-packed and visually inspected prior to dispatch

Key Features

- Original ABB spare – Ensures mechanical fit, connector alignment, and firmware/revision consistency in ABB drive systems.

- UNS0881a-P;V1 hardware revision – Stable hardware version favored in many installed bases for maintenance standardization.

- Host-powered board – Draws regulated logic power from the drive backplane; no external PSU needed.

- Low-voltage control & signal conditioning – Designed for reliable internal signaling and inter-board communication inside the drive.

- Service-friendly replacement – Board-level swap that, in most cases, restores control functionality without cabinet rewiring.

- ESD-robust handling – Conformal/board protection practices from ABB manufacturing; ship-ready in anti-static packaging.

Technical Specifications

| Brand / Model | ABB UNS0881a-P;V1 |

| Manufacturer Part No. | 3BHB006338R0001 |

| HS Code | 8538.90 (Parts suitable for the apparatus of heading 8537) |

| Product Type | Drive control/interface PCB (internal to ABB industrial drives) |

| Power Requirements | Powered by host drive backplane (logic-level rails; no separate supply) |

| Operating Temperature | Follows host drive specification; typically 0 to +55 °C environment inside cabinet |

| Signal I/O Types | Low-voltage digital/analog control signals and inter-board links (as per drive configuration) |

| Communication Interfaces | Proprietary board-to-board/backplane connectors used within ABB drive control sections |

| Installation Method | Internal mounting in drive cabinet; secured with screws/standoffs; ESD-safe handling required |

Application Fields

You’ll typically find the UNS0881a-P;V1 inside ABB variable-speed drive systems used across:

- Metals and mining – mill drives, conveyors, and crushers where uptime is critical

- Cement and aggregates – kiln fans, baghouse blowers, raw mill drives

- Pulp & paper – line drives, winders, and section controls

- Power & utilities – auxiliary drives in balance-of-plant systems

- Marine & offshore – pump and winch drive cabinets

- Water & wastewater – aeration blowers and high-efficiency pumping

One thing I appreciate is how it slots into existing ABB drive architectures without forcing field rewiring—handy for midnight callouts when the line has to be running before shift change.

Advantages & Value

- Reliability – Genuine ABB board designed for continuous operation in control compartments.

- Compatibility – Matches the mechanical layout and backplane interfaces used in many ABB drive frames.

- Downtime reduction – Quick board swap in most cases; no re-engineering required.

- Lifecycle support – Easier spare planning when standardizing on the V1 hardware revision.

- Total cost control – Avoids expensive cabinet modifications and shortens maintenance windows.

A maintenance supervisor at a cement plant told us their team keeps one UNS0881a-P;V1 on-hand per line. When a control fault pops up, swapping this board has, in many cases, brought the drive back within an hour—no waiting for a specialized service call.

Installation & Maintenance

- Environment – Install inside a clean, ventilated cabinet per ABB drive guidelines; avoid conductive dust and moisture.

- ESD safety – Use a grounded wrist strap and ESD mat; handle by edges only.

- Wiring – Power and signals are via backplane/board connectors; seat fully and verify latch engagement.

- Firmware/parameters – Back up the drive’s parameters before replacement; restore and verify checksums after swap.

- Routine care – Periodic cabinet cleaning with dry air (low pressure); check connector integrity during scheduled shutdowns.

- Documentation – Follow the specific ABB drive service manual for slot position, torque specs, and revision notes.

Quality & Certifications

- Manufactured under ABB quality systems (ISO 9001)

- CE marking applies at the drive/system level

- RoHS compliance depends on production batch/revision; many later revisions are compliant

- Warranty: 12 months (365 days) from shipment

Tip: If your current board shows a different minor revision, share the exact part label and drive typeplate. We can verify interchangeability, so you avoid compatibility surprises during the change-out.

Reviews

There are no reviews yet.