Description

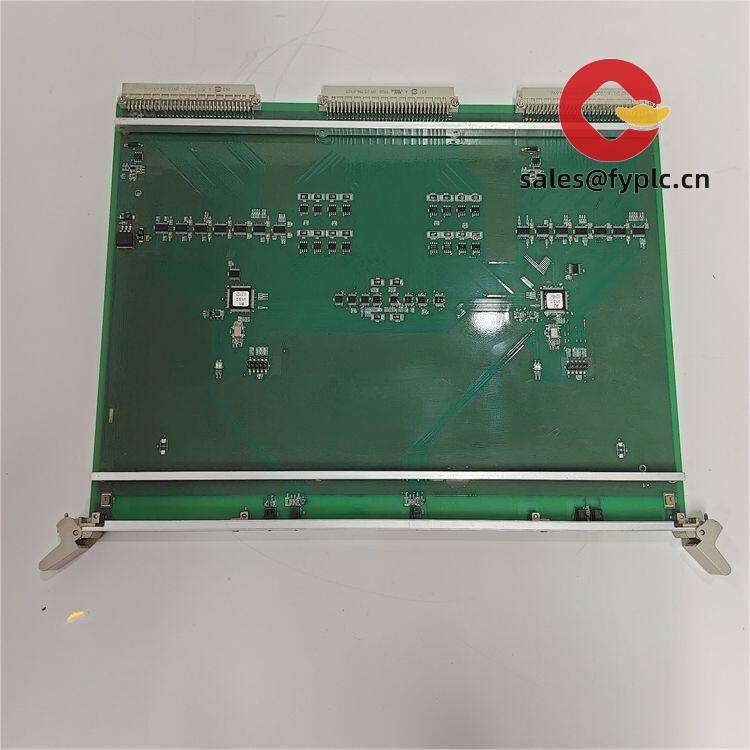

ALSTOM I/OBUS2 12004-103-01 V1.20 – I/O Bus Interface Module for Legacy ALSTOM Control Cabinets

The ALSTOM I/OBUS2 12004-103-01 (Version V1.20) is a dedicated I/O bus interface board used in legacy ALSTOM control systems, typically found in turbine/generator controls, ALSPA-based DCS racks, and various plant auxiliaries. From my experience, this module acts as the deterministic bridge between the main controller backplane and distributed I/O segments, keeping time-critical signals flowing reliably in brownfield installations. If you’re maintaining an installed base, this card is often the drop-in spare that gets a line back up with minimal engineering.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Documentation: photos of the actual unit and test report before shipment, on request

Key Features

- Designed for ALSTOM I/OBUS2 backplanes – Ensures proper timing and bus arbitration with legacy ALSTOM racks.

- Firmware Version V1.20 – Stable field-proven revision that typically matches many installed systems, reducing compatibility risks.

- Backplane-powered – No external PSU wiring; power is supplied by the host cabinet for cleaner integration.

- Status indication – You might notice onboard LEDs for run/fault/bus status, which helps technicians diagnose issues at the panel.

- Field-replaceable – Cold-swap recommended to protect the backplane and minimize bus disturbances.

- Proprietary multi-drop bus – Typically uses an industrial physical layer (often RS-485-based) to link distributed I/O nodes with predictable latency.

Technical Specifications

| Brand / Model | ALSTOM I/OBUS2 12004-103-01, Version V1.20 |

| Function | I/O bus interface module for ALSTOM control racks (I/OBUS2) |

| HS Code | 8538.90 (Parts for electrical control or distribution equipment) |

| Power Requirements | Powered via host backplane; no external power input required |

| Operating Temperature | Typically 0 to +55°C when installed in a ventilated control cabinet |

| Signal I/O Types | No direct field I/O; provides bus communication between CPU/backplane and remote I/O nodes |

| Communication Interfaces | ALSTOM I/OBUS2 proprietary interface (commonly RS-485 physical layer in many cases) |

| Installation Method | Plug-in rack card for ALSTOM cabinets; cold-swap recommended |

Application Fields

This module is commonly used in:

- Power generation control systems (steam, gas, and hydro turbines) using legacy ALSTOM/ALSPA architectures

- Plant distributed control cabinets for auxiliaries: feedwater, condensate, and balance-of-plant I/O segments

- Process industries that still rely on ALSTOM racks for deterministic I/O handling

One thing I appreciate is how it helps extend system life without forcing a full cabinet redesign—especially useful during phased migrations where downtime windows are tight.

Advantages & Value

- Form-fit compatibility – Minimizes engineering changes during maintenance or retrofit work.

- Reduced risk – Keeping firmware at V1.20 typically avoids unforeseen behavior with existing CPU and I/O firmware sets.

- Lower downtime – Swapping the card is straightforward for a trained technician; bus status LEDs guide quick checks.

- Procurement clarity – Traceable part/model info and test documentation available before shipment.

Simulated customer feedback: “We used the 12004-103-01 V1.20 in a scheduled outage to stabilize an intermittent I/O segment. Commissioning was uneventful and the unit has been running clean since.”

Installation & Maintenance

- Cabinet environment – Install in a DIN 41494-style or equivalent 19-inch enclosure with adequate ventilation; avoid hotspots near power supplies.

- Wiring and grounding – Ensure shield continuity and proper cabinet earthing; keep bus cabling separated from high-voltage runs to reduce noise.

- Handling – Observe ESD precautions; power down the rack before replacement (cold-swap) to protect the backplane.

- Routine checks – Periodically inspect connectors for oxidation, clean dust filters, and verify bus integrity during planned outages.

- Firmware alignment – Maintain Version V1.20 when matching existing nodes, unless your site standard specifies a different tested pairing.

Quality & Certifications

- Quality status – Supplied as an original ALSTOM hardware unit; each piece is function-tested before dispatch.

- Certifications – Factory hardware for this family typically conforms to CE (EMC/Low Voltage) at the system level.

- Warranty – 365 days coverage.

- Traceability – Serial and version information recorded on delivery documents.

Related/Supporting Components

For smoother maintenance, teams often procure companion parts alongside this module:

- ALSTOM backplane segments for I/OBUS2 racks

- Remote I/O node interface boards and I/O slices matching the same bus generation

- Cabinet PSU modules and bus terminators where applicable

Reviews

There are no reviews yet.