Description

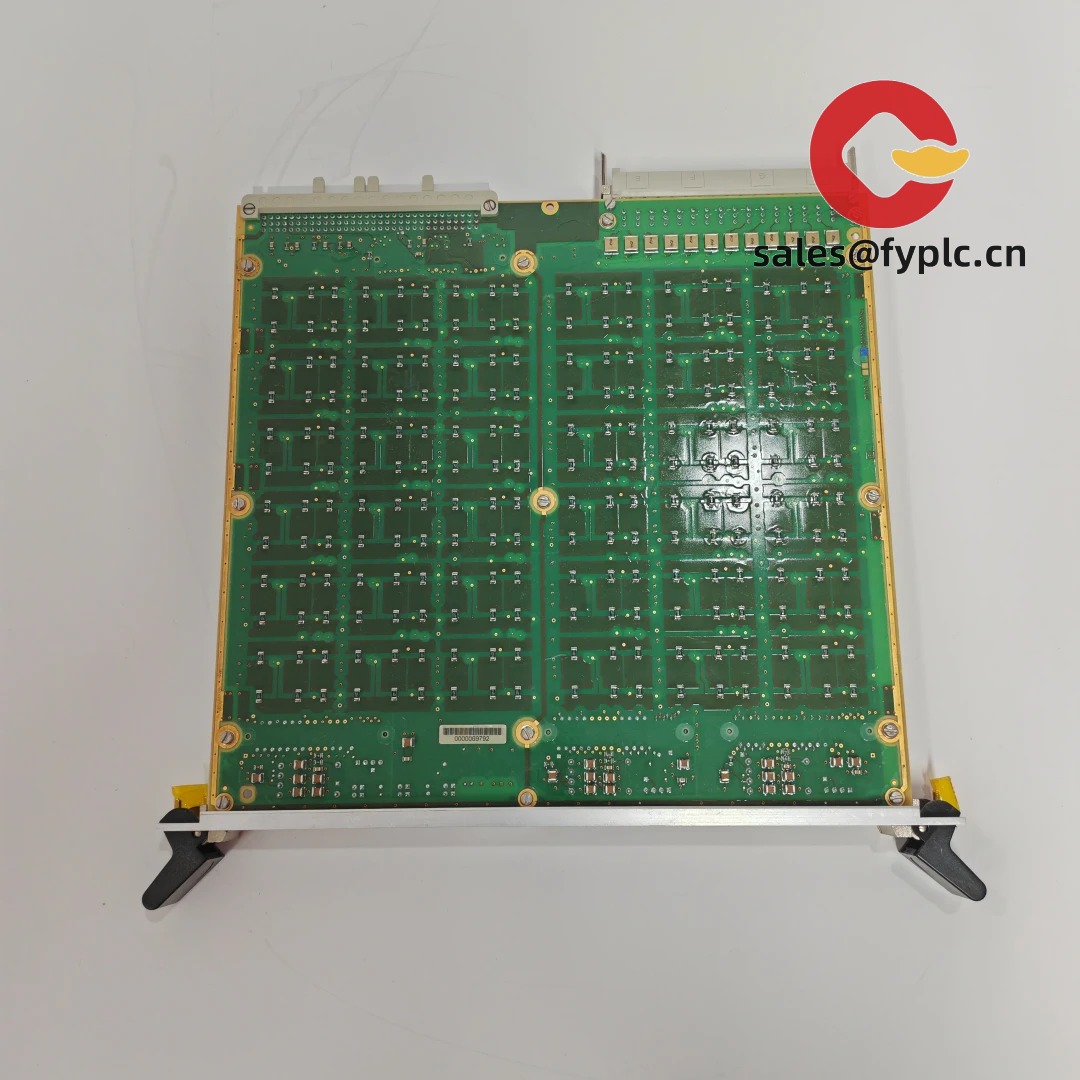

ALSTOM I/OBE2 12004-104-00 V1.0.0 – I/O Bus Extension Module for Legacy ALSTOM Control Systems

The ALSTOM I/OBE2 12004-104-00 V1.0.0 is a legacy I/O bus extension board designed to sit inside ALSTOM control racks, bridging the controller backplane to downstream I/O segments. From my experience, it’s typically found in older ALSTOM DCS/PLC cabinets (often in turbine, boiler, and balance-of-plant applications) where stable backplane communication and predictable latency matter more than feature novelty. If you’re maintaining installed ALSTOM systems, this board helps keep the rack architecture intact without redesigning field wiring or software.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Backplane I/O bus extension – Links controller and remote/expanded I/O segments within ALSTOM rack architectures, keeping legacy systems operational.

- Rack-integrated design – Installs directly in the ALSTOM chassis; no external field wiring to the module itself in most cases.

- Backplane-powered – Draws power from the host rack, reducing panel wiring complexity.

- Stable, deterministic signaling – Prioritizes consistent rack-level communication, which seems to be why it’s still favored in mature plants.

- Service-friendly hardware – Captive fasteners and card-edge guides make removal/replacement straightforward during scheduled downtime.

- Version-marked hardware – V1.0.0 helps maintenance teams align spares with installed revisions.

Technical Specifications

| Brand / Model | ALSTOM I/OBE2 12004-104-00 V1.0.0 |

| HS Code | 853890 (Parts for electrical control panels and apparatus) |

| Power Requirements | Powered via ALSTOM rack backplane; no external power input on the module |

| Dimensions & Weight | Standard ALSTOM rack-slot form factor for the 12004-series; contact for outline drawing if needed |

| Operating Temperature | Typically 0 to +55 °C when installed in a ventilated control cabinet |

| Signal I/O Types | Backplane bus extension; no direct field signal termination on this board |

| Communication Interfaces | Proprietary ALSTOM rack backplane; no front-panel Ethernet/serial |

| Installation Method | Rack-mounted in ALSTOM chassis; secured with captive screws; ESD-safe handling required |

Application Fields

You’ll typically see the I/OBE2 in legacy ALSTOM control cabinets supporting:

- Gas and steam turbine control (governor, protection I/O segmentation)

- Boiler/BOP sequences in power generation DCS cabinets

- Industrial process lines where ALSTOM PLC/DCS racks are still the main controller

- Modernization projects keeping existing I/O and wiring while replacing only select rack components

One thing I appreciate is how it lets sites retain proven field I/O while extending or reorganizing the rack bus—handy when downtime windows are tight and rewiring isn’t an option.

Advantages & Value

- Reliability in legacy racks: Keeps established ALSTOM backplane architectures running without software or wiring changes.

- Compatibility: Designed for ALSTOM rack systems; no protocol gateways or adapters in typical use.

- Cost-saving path: Extends system life and defers full migration costs; many plants use it to bridge upgrade phases.

- Technical support availability: We can help verify fit with your rack revision and advise on slotting and addressing conventions.

A maintenance lead at a gas plant told us they swapped an I/OBE2 during a weekend outage and avoided touching any marshalling terminals—exactly the type of low-risk change that keeps schedules intact.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated control cabinet. Maintain ambient within the typical 0–55 °C range and keep humidity non-condensing.

- Wiring and earthing: No direct field wiring on the module; ensure cabinet grounding is intact and backplane connectors are clean.

- Mounting: Power down and lock out/tag out before removal. Slide the card along guides, seat fully into the backplane, and secure with captive screws.

- ESD safety: Use a grounded wrist strap and ESD-safe surface during handling.

- Routine care: Visually inspect connectors during outages, remove dust with dry air, and verify any DIP/rotary addressing matches the site configuration if present.

- Firmware: This is a hardware-level extender; field firmware updates are typically not applicable. Keep controller firmware aligned with the site standard.

Quality & Certifications

- Manufacturer quality system: ISO 9001 (typical for ALSTOM manufacturing)

- CE conformity at the cabinet/system level where applicable

- RoHS status may vary for legacy production; confirm by serial/batch if needed

- 365-day warranty provided by us on supplied units

Related/Supporting Components

If you’re planning a like-for-like replacement or an extension, you might also consider:

- ALSTOM rack chassis for 12004-series modules (matching slot/keying)

- Controller CPU boards compatible with the same backplane family

- I/O modules (digital/analog) used on the extended bus segment

- Backplane connectors and retention hardware for field swaps

If you can share your cabinet photos or the rack bill of materials, we’ll help verify slot compatibility and advise on a clean installation plan. You might notice the process is usually faster when we check the backplane revision against the V1.0.0 board label in advance.

Reviews

There are no reviews yet.