Description

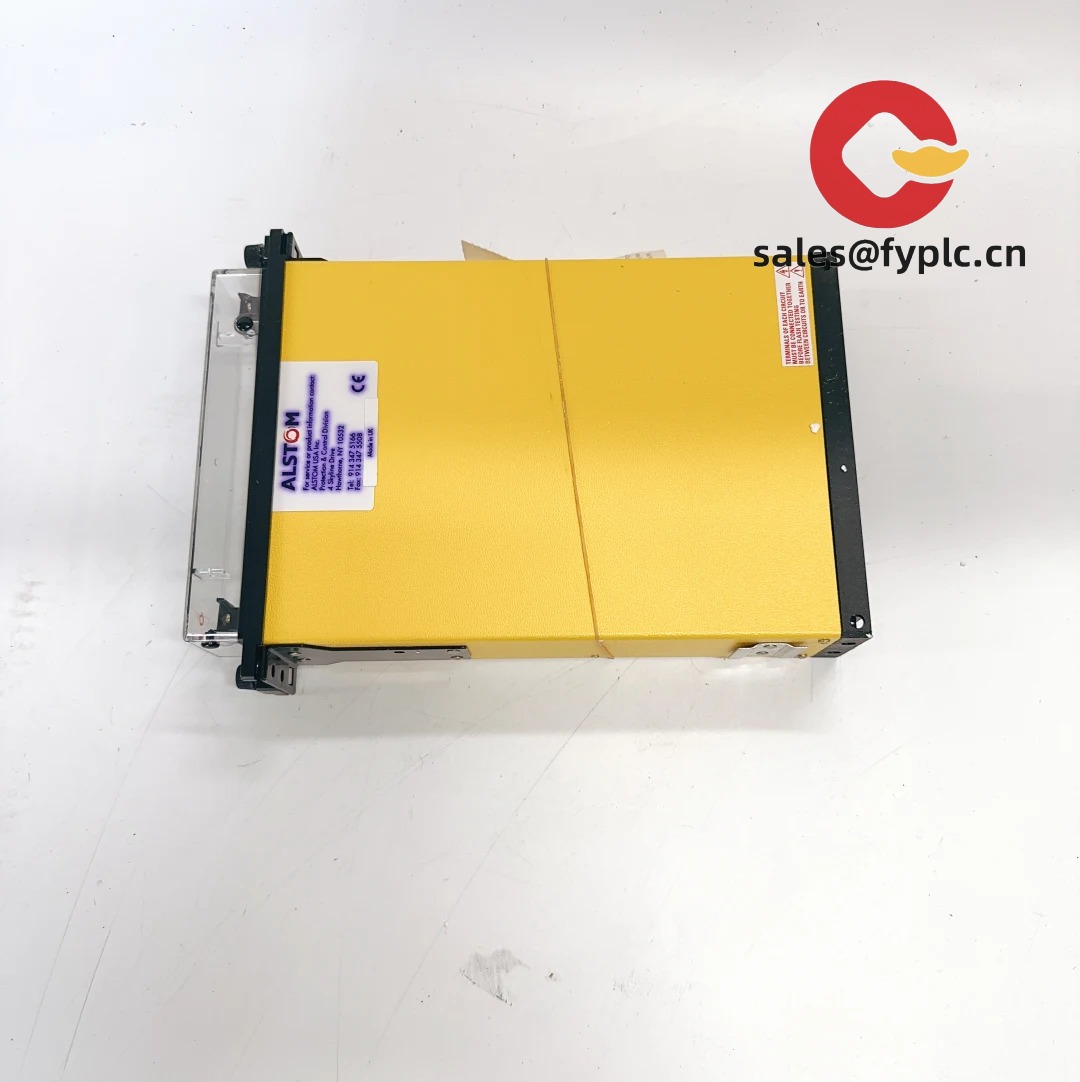

ALSTOM MVAW11B1AB0513A – Heavy‑duty Auxiliary/Tripping Relay for Protection & Switchgear Panels

The ALSTOM MVAW11B1AB0513A is part of the well-known MVA series of industrial auxiliary/tripping relays used in substations and switchgear control panels. From my experience, the MVAW variants are picked when you need dependable mechanical contacts, clear status indication, and long service life under utility-grade conditions. It’s typically used for trip circuits, interlocking, and breaker status signaling, and it fits nicely as a drop‑in replacement in many legacy ALSTOM/AREVA/GEC relay panels.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express: FedEx, UPS, DHL

Key Features

- Utility‑grade reliability – Designed for continuous service in protection and control circuits, with robust mechanics that typically outlast standard general‑purpose relays.

- Heavy-duty changeover contacts – Dry contacts for trip/alarm duties; commonly used for breaker trip coils, lockout chains, and permissive signals.

- Panel/draw‑out case – You might notice the familiar ALSTOM withdrawable case that simplifies front access, inspection, and quick swap.

- Compatible with legacy panels – In many cases it’s a direct retrofit into existing ALSTOM/AREVA/GEC schemes, reducing rewiring time.

- Wide coil options – Typically available in DC and AC coils (e.g., 24/48/110/125/220), so matching site voltage is straightforward.

- No firmware, no surprises – Pure electromechanical operation; no configuration software, which maintenance teams often appreciate.

Technical Specifications

| Brand / Model | ALSTOM MVAW11B1AB0513A |

| HS Code | 8536.49 (Other relays for a voltage > 60 V) |

| Type | Electromechanical auxiliary / tripping relay (protection panel duty) |

| Power (Coil) Requirements | DC or AC coil variants; this MVAW11 series is commonly supplied in 110–125 VDC for utility panels; other coil voltages available on request |

| Contacts / Ratings | Changeover (dry) contacts; typical rating 5 A at 250 VAC or 30 VDC (resistive) |

| Dimensions & Weight | Approx. 170 × 106 × 203 mm; ~2.0–2.6 kg (typical ALSTOM withdrawable case) |

| Operating Temperature | Typically −10 °C to +55 °C (indoor switchgear panels) |

| Signal I/O Types | Dry contact outputs (NO/NC) for trip, alarm, permissive, and interlock circuits |

| Communication Interfaces | None (electromechanical) |

| Installation Method | Panel/flush mounting with withdrawable case for front access and quick replacement |

Application Fields

This model is typically used in:

- High/medium-voltage substations – trip circuit supervision, lockout, and breaker status signaling

- Switchgear OEM and retrofit – interlocking and permissive control chains

- Power plants and industrial utilities – start/stop sequences, alarms, and tripping logic

- Process plants – when a robust mechanical relay is preferred over a PLC output for critical trips

A maintenance supervisor at a 110 kV site told us the MVA relays “just keep going,” and when a panel refurb is needed, the draw‑out case makes testing and swap‑over much faster than DIN plug‑ins.

Advantages & Value

- Reliability under real fault conditions – One thing I appreciate is how these contacts hold up during high‑burden trip events.

- Compatibility – Often a direct replacement in legacy ALSTOM/AREVA/GEC protection schemes, minimizing design changes.

- Lower lifecycle cost – No firmware or config tools; routine mechanical checks are usually all that’s needed.

- Technical support – We can help validate coil voltage, contact form, and case fit so it lands right the first time.

Installation & Maintenance

- Mounting – Install in a clean, dry relay cabinet or switchgear panel; allow front clearance for the withdrawable case. Avoid continuous vibration where possible.

- Wiring – Use appropriately rated control wiring for coil and contacts; torque terminals per standard practice. For trip circuits, keep runs short and check continuity/insulation.

- Ventilation – Normal panel ventilation is sufficient; coil heating is modest in most cases.

- Safety – De‑energize and isolate trip circuits before removing the relay; verify absence of control voltage with a meter.

- Routine checks – Periodically exercise the relay, verify pickup/dropout, clean dust from the case, and measure contact resistance. No firmware updates are required.

Quality & Certifications

- Standards: Designed to conform with IEC/EN 60255 series for protection relays

- CE Marking: Present on later production runs of the MVA family

- RoHS: Status can vary by build year; RoHS‑conforming supply is available on request

- Warranty: 365 days (exchange/repair per our standard policy)

If you’d like, share your required coil voltage and contact configuration, and we’ll match the MVAW11B1AB0513A variant to your panel spec before shipping. You might notice that getting the coil code right up front typically shortens commissioning time.

Reviews

There are no reviews yet.