Description

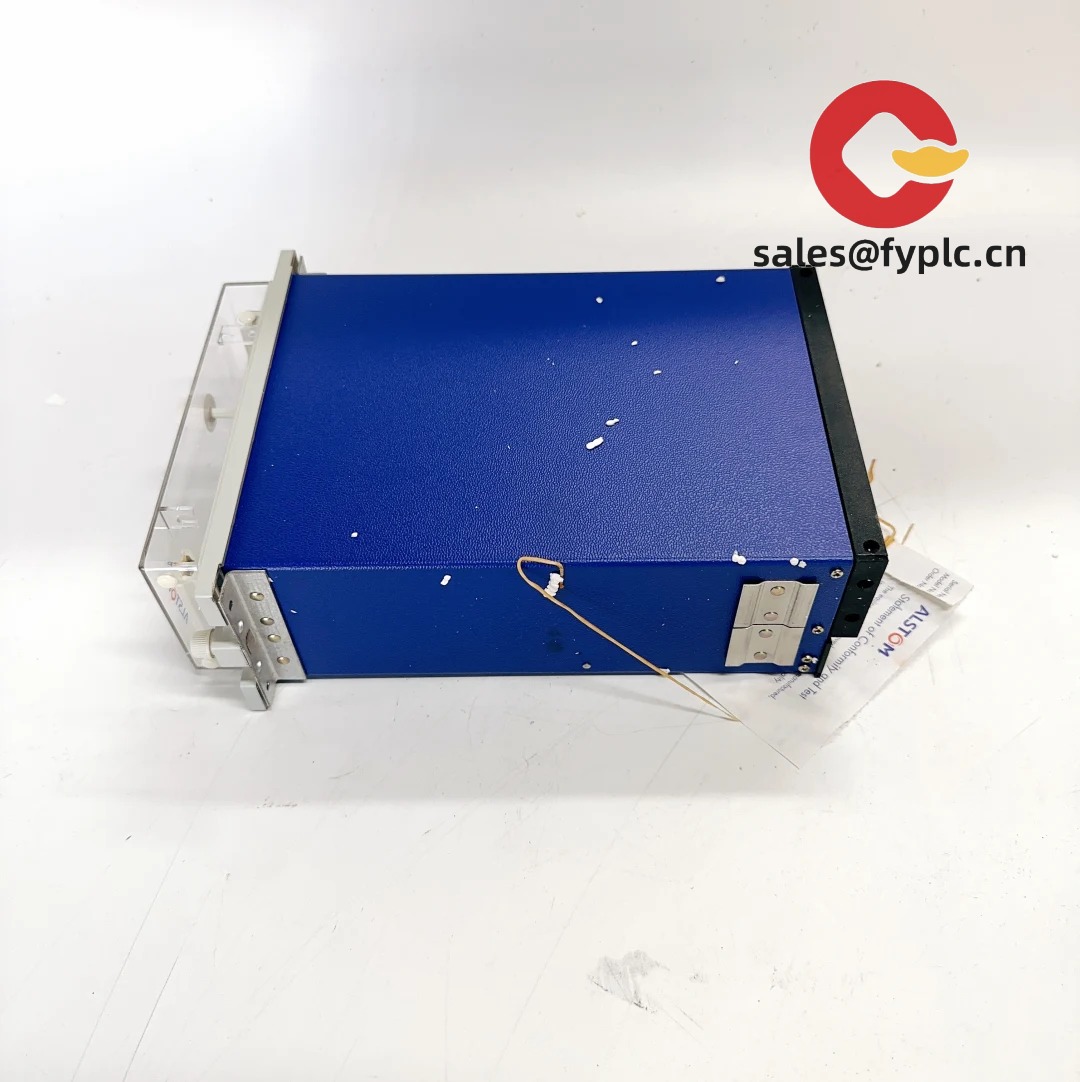

ALSTOM MVTU11K1CD0751G – Voltage Transducer/Measurement Module for Protection and Control Systems

The ALSTOM MVTU11K1CD0751G is a specialized voltage transducer/measurement module designed to plug into ALSTOM protection and control platforms. From my experience, MVTU-series boards are used to condition and digitize AC voltage inputs (often multi-phase) so the host relay can perform protection, metering, and disturbance recording with stable accuracy. If you’re maintaining legacy ALSTOM installations or planning a like-for-like replacement to reduce downtime risk, this module is typically the right fit without re-engineering the panel.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in-stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Plug-in design – Installs directly into the host ALSTOM relay/chassis slot, keeping wiring changes to a minimum.

- Multi-phase voltage sensing – Conditions and feeds measured AC voltages to the host for protection, metering, and power quality functions.

- Stable scaling and isolation – Typically provides galvanic isolation and consistent scaling for reliable protection algorithms, even in noisy substations.

- Backplane powered – No separate external power; draws regulated power rails from the host platform.

- Service-friendly – Front-access card with guided insertion/extraction; you might notice maintenance is faster compared to rewiring discrete transducers.

- Drop-in replacement for MVTU-series – In many cases, offers straightforward retrofit to restore system availability after a board fault.

Technical Specifications

| Item | Specification |

|---|---|

| Brand / Model | ALSTOM MVTU11K1CD0751G |

| HS Code | 8538.90 (Parts suitable for use with switchgear and control equipment) |

| Power Requirements | Powered via host backplane; no external supply required |

| Signal Input/Output Types | AC voltage inputs (multi-phase sensing), conditioned and transferred to host via internal backplane |

| Communication Interfaces | None on-board; communications handled by host relay platform |

| Installation Method | Plug-in module for ALSTOM host chassis; ESD-safe handling required |

Application Fields

This module is commonly used in substation protection panels, MV/HV switchgear bays, and generator or motor protection systems where precise voltage measurement is needed for functions such as under/over-voltage, voltage-controlled overcurrent, directional elements, and synch-check. Utilities, oil & gas, metals, mining, and large industrial plants typically keep MVTU boards on hand to reduce outage time during relay maintenance.

A maintenance engineer shared that replacing a faulty MVTU board restored a feeder protection relay within a single shift—no panel rewiring, just a controlled power-down, card swap, and verification of measurements on the relay HMI.

Advantages & Value

- Reliability – Purpose-built measurement chain for protection; seems to be less sensitive to noise than generic transducers.

- Compatibility – Designed for ALSTOM host platforms, reducing integration uncertainty in retrofit projects.

- Cost control – Limits engineering time; typically a like-for-like swap without redesigning CT/VT wiring.

- Service and spares – Faster MTTR in many cases; easy to stock as a field-replaceable module.

Installation & Maintenance

- Panel and cabinet – Install in a clean, ventilated enclosure meeting standard substation control cabinet practices; maintain ambient conditions per the host relay’s datasheet.

- Wiring – VT wiring lands on the host/chassis terminals; the MVTU module interfaces via the internal backplane. Verify polarity and burden checks before energizing.

- ESD and handling – Use antistatic wrist straps and handle by the edges. De-energize the host before insertion/removal.

- Routine checks – Periodically confirm measured voltages against a calibrated source; review event and disturbance records for anomalies.

- Firmware/Settings – Any firmware and logic reside in the host relay; keep host firmware updated and back up settings after commissioning.

- Cleaning – Keep slots and card edge connectors free of dust; use non-residue contact cleaner if oxidation is suspected.

Quality & Certifications

- Typically CE-marked ALSTOM protection platform component; designed for IEC 60255 protection relaying environments

- RoHS compliance common for later production runs

- Manufacturing quality aligned with ISO 9001 processes

- Supplier warranty: 12 months (365 days)

If you’re matching a specific relay chassis, share the host model and firmware context, and we’ll confirm slot compatibility and any required accessories. In many cases, we can suggest supporting components such as matching I/O cards, power supply modules, or front terminal kits to complete the service kit for your relay bay.

Reviews

There are no reviews yet.