Description

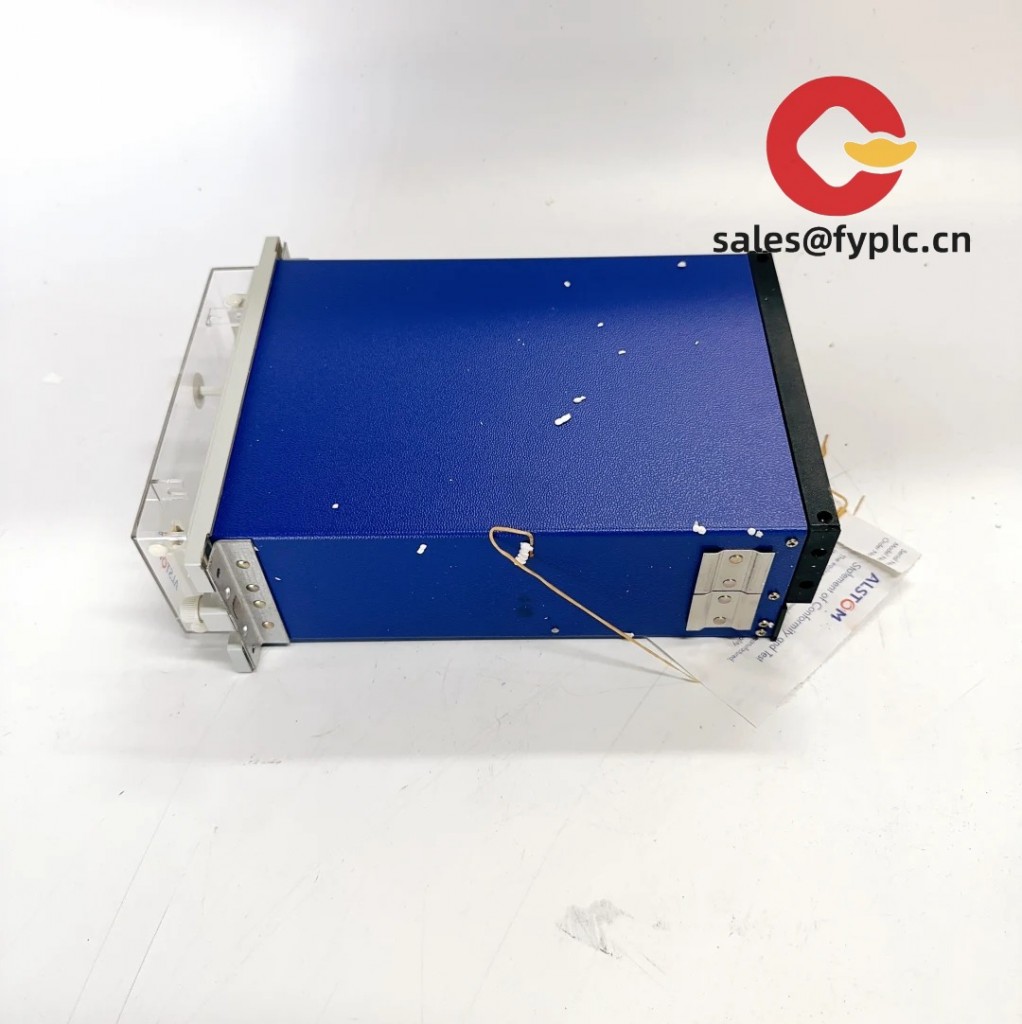

ALSTOM N70032702L – Plug-in Control Board for Rail and Industrial Control Cabinets

The ALSTOM N70032702L is a board-level module designed to slot into ALSTOM control racks, typically used across rolling stock subsystems and fixed-installation control cabinets. From my experience, this kind of module is chosen as a form-fit-function replacement to keep legacy and current Alstom platforms running safely with minimal re-engineering. You might notice that it’s built for backplane-powered operation and rack-to-field wiring, which makes field swap-outs quick and predictable during tight service windows.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days from delivery

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Rack-mounted, backplane powered: No external power wiring; the board draws power from the host chassis to simplify installation.

- Form-fit-function replacement: Intended as a direct swap for the same model in existing ALSTOM cabinets, limiting downtime.

- Industrial/rail-grade design: Typically engineered for vibration, electrical noise, and temperature ranges encountered in rolling stock and trackside environments.

- Service-friendly handling: Front access for insertion/removal with guided rails; ideal for depot maintenance practices.

- Backplane bus interfacing: Signals and communication managed via the rack’s proprietary backplane, keeping field wiring on the enclosure side.

Technical Specifications

| Brand / Model | ALSTOM N70032702L |

| HS Code | 853890 (Parts for electrical control panels/assemblies) |

| Power Requirements | Supplied via host rack backplane; no external supply connection |

| Dimensions & Weight | Plug-in board form factor (Eurocard-style footprint is common); weight typically in the 0.2–0.4 kg range |

| Operating Temperature | Designed for industrial/rail cabinets; many installations target -25°C to +70°C when properly ventilated |

| Signal I/O Types | Logic-level and conditioned signals via the proprietary backplane; field I/O typically terminated on rack connectors |

| Communication Interfaces | Proprietary ALSTOM backplane bus; external comms handled at the cabinet level |

| Installation Method | Plug-in card; guided rails and locking hardware in ALSTOM rack; mating to rear backplane connector |

Notes: Specifications above reflect typical usage for this model family in ALSTOM control racks. Exact details can vary by hardware revision and application context.

Application Fields

- Rolling stock subsystems: traction control, auxiliary converters, HVAC, or braking control cabinets

- Trackside/wayside control and protection panels in signaling and power distribution

- Depot test benches and refurbishment programs where form-fit-function spares are required

- Industrial process cabinets leveraging ALSTOM control racks in legacy upgrades

Advantages & Value

- Downtime reduction: Swap like-for-like to restore service quickly—especially useful for fleet operators on tight schedules.

- Compatibility first: Maintains existing wiring, backplane allocation, and cabinet layout; minimal engineering risk.

- Lifecycle savings: Avoids premature system retrofits; extends the service life of proven ALSTOM platforms.

- Technical support: We assist with identification by photo/part tag and cross-checking revisions to ensure the right fit.

Installation & Maintenance

- Cabinet standards: Install in a clean, ventilated rack; maintain airflow paths and keep within enclosure thermal limits.

- Wiring: No field wiring to the board itself—signals route through the rack backplane and terminal blocks; verify slot mapping before insertion.

- ESD & handling: Use antistatic wrist straps and transport in ESD-safe packaging; avoid touching component leads.

- Safety: Isolate cabinet power and lock-out/tag-out before removal/installation; wait for any capacitive discharge window per maintenance manual.

- Routine upkeep: Periodically clean card guides and connector areas with approved non-residue methods; check for oxidation on backplane contacts.

- Firmware/config: If the application uses board-level configuration or CAL data, back up before swap and restore after—this avoids tuning drift.

Quality & Certifications

- Quality system: Manufactured under ISO 9001 quality frameworks (typical for ALSTOM supply chain)

- Compliance: CE marking and RoHS applicability depend on the specific hardware revision and target market

- Rail standards: Many deployments target EN 50155 / EN 50121 environments; verify per project specification

- Warranty: 365-day warranty provided by us on supplied units

Supporting Components (for Planning)

- Host rack/backplane compatible with ALSTOM N70032702L slot assignment

- Rack power supply module and cabinet-level EMC/grounding hardware

- Terminal blocks and harnesses for field I/O on the cabinet side

- Front-panel hardware (insertion handles, guide rails) for serviceability

One thing I appreciate is how predictable these ALSTOM plug-in boards are during replacement. In many cases, a customer swaps an N70032702L like-for-like and the cabinet passes commissioning checks on the first shot—no rewiring, no new drawings, just a clean slot-in. If you can share the rack photo and the card’s revision label, we’ll validate compatibility before shipping.

Reviews

There are no reviews yet.