Description

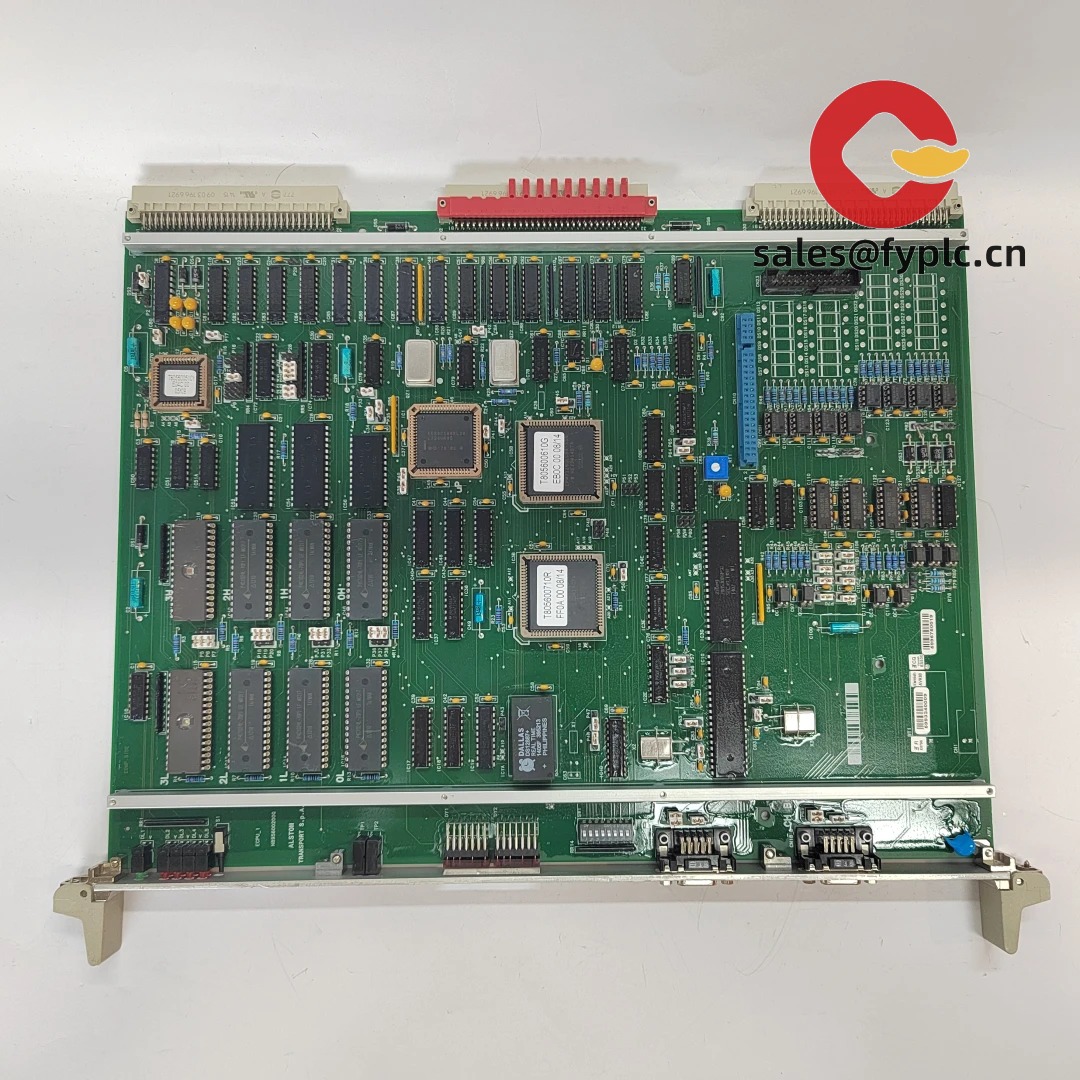

ALSTOM ECPU_1 (N895600512D / N895600051C / N895600200Q) – Central Processor Module for Legacy Control and Protection Racks

The ALSTOM ECPU_1 is the core processor board used in many legacy ALSTOM rack-based control and protection platforms. From my experience, this module typically sits in the main CPU slot, coordinating sequence control, fast interlocks, and communications to local/remote I/O.

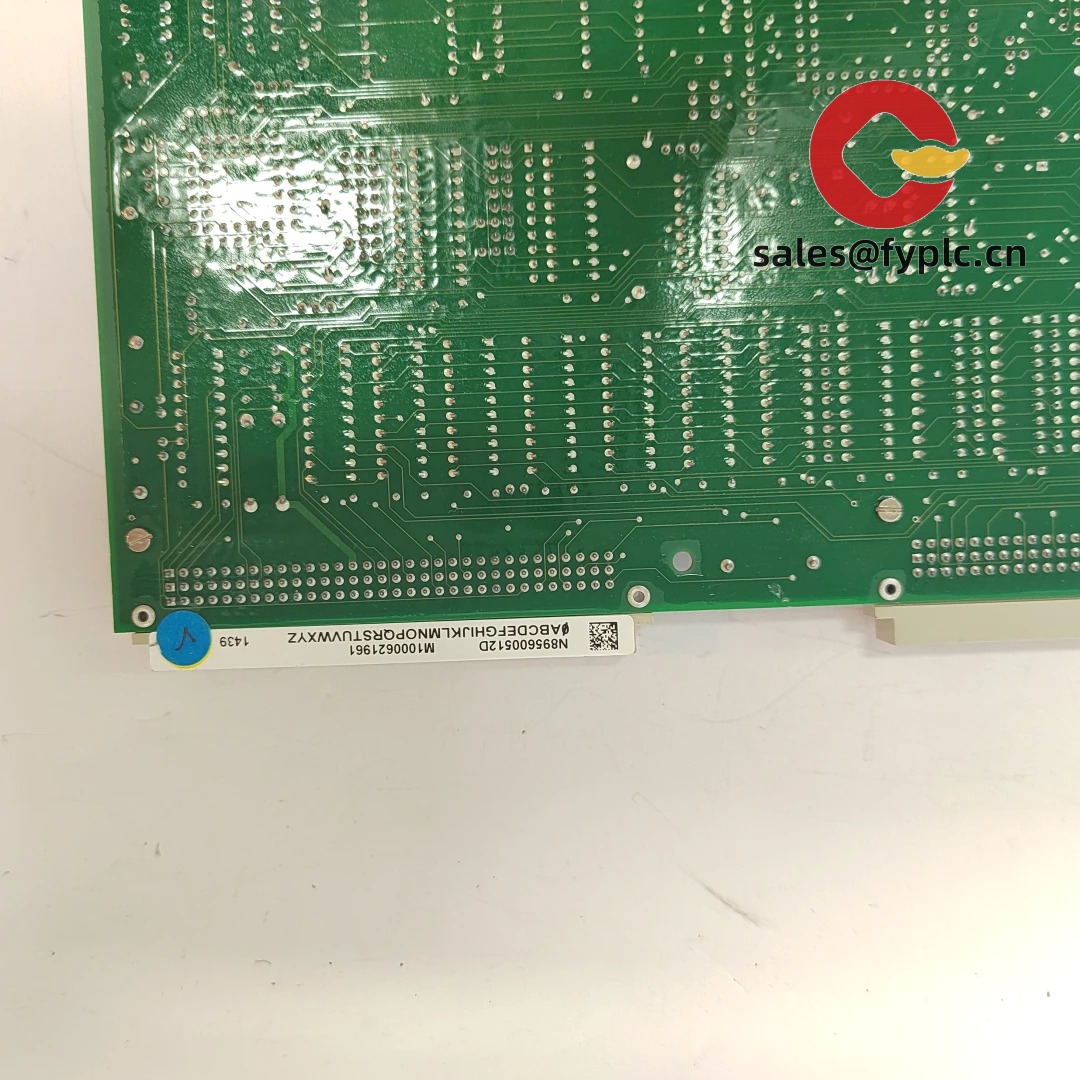

The part numbers N895600512D, N895600051C, and N895600200Q are commonly seen as assembly or revision identifiers tied to the ECPU_1, and they help match form-fit-function in existing cabinets.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Real-time deterministic control – Handles fast logic, sequencing, and protection interlocks typically required in power and process applications.

- Backplane integration – Interfaces directly with the system backplane for low-latency access to I/O and power.

- Fieldbus and service connectivity – You might notice serial service ports and, on some revisions, Ethernet for engineering or peer-to-peer comms.

- On-board diagnostics – Front-panel status LEDs support quick fault isolation during commissioning or maintenance.

- Firmware upgradable – Supports field firmware loading using the engineering toolset (revision-dependent in many cases).

- Serviceable plug-in design – Minimizes downtime; typically swap-and-configure with existing backplane.

- Revision compatibility – N895600512D, N895600051C, and N895600200Q are associated part numbers used to match the right CPU for the installed base.

Technical Specifications

| Brand / Model | ALSTOM ECPU_1 (P/Ns: N895600512D / N895600051C / N895600200Q) |

| HS Code | 8538.90 – Parts suitable for apparatus of 8535/8536/8537 (industrial control parts) |

| Power Requirements | Supplied via system backplane; 5 VDC rail typical, ~10–15 W (depends on revision and loading) |

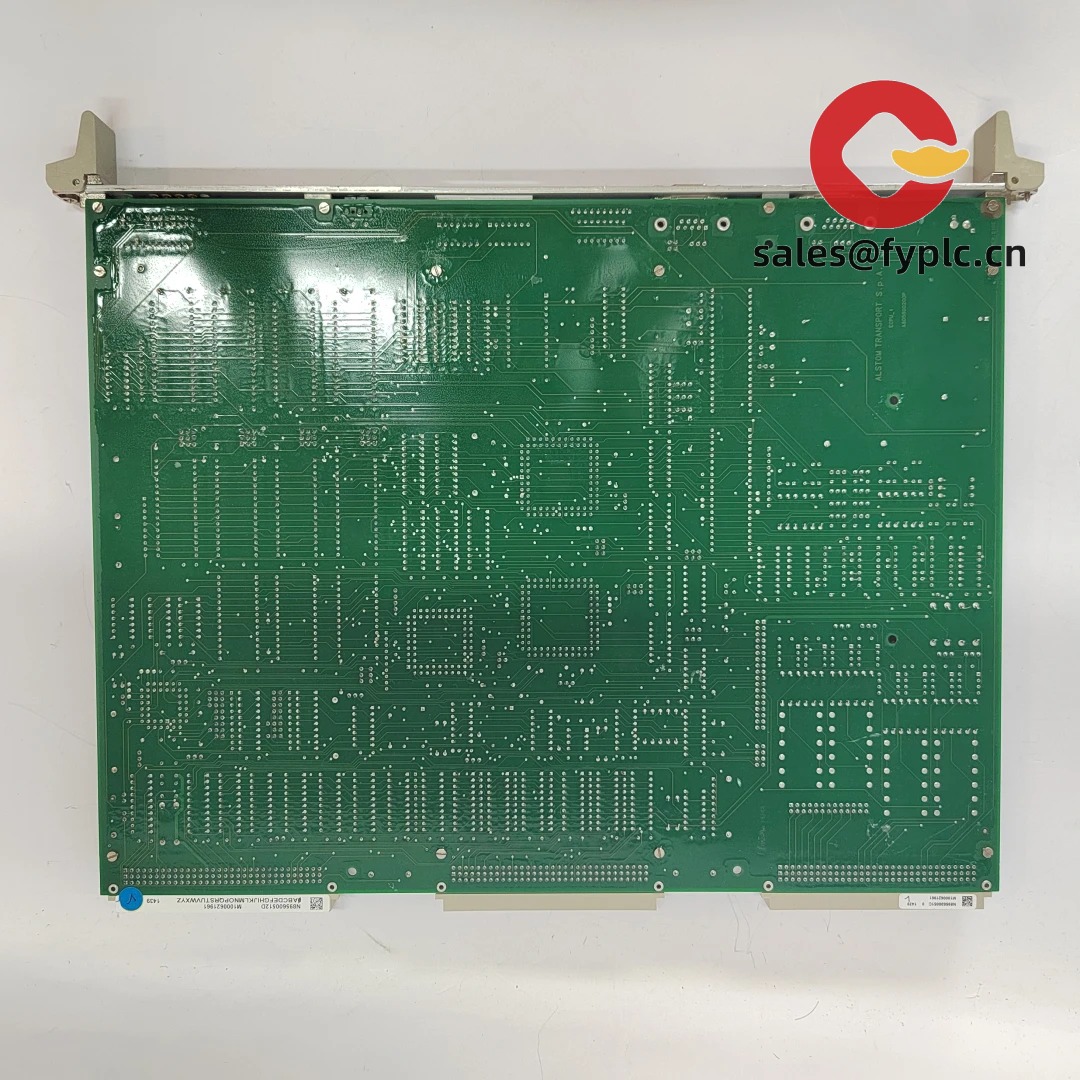

| Dimensions & Weight | 6U plug-in rack card (Eurocard style), approx. 233 × 160 mm; typically under 1 kg |

| Operating Temperature | 0 to +55 °C ambient in control cabinet; 5–95% RH non-condensing (typical for this series) |

| Signal I/O Types | CPU handles logic and comms; process I/O (DI/DO, AI/AO, RTD/TC) via companion modules on the rack or remote I/O |

| Communication Interfaces | Backplane bus; service serial ports (RS‑232/RS‑485 typical); Ethernet 10/100 on certain revisions for engineering/peer links |

| Installation Method | Plug-in to ALSTOM system rack/backplane; front panel access; secure with card guides and locking levers; grounding per cabinet spec |

| Firmware/Software | Field-upgradable firmware; configuration with the designated ALSTOM engineering toolset (revision-dependent) |

Application Fields

This CPU is typically deployed across power generation and industrial utility systems where deterministic control is required:

- Steam and gas turbine auxiliaries: start/stop sequences, lube oil systems, fuel handling, overspeed interlocks.

- Boiler and balance-of-plant control in thermal plants.

- Substation automation and bay control where legacy ALSTOM racks remain in service.

- Water treatment, compressors, and critical process skids tied to plant-wide DCS.

- Retrofit/maintenance projects seeking a form-fit-function replacement without re-engineering the cabinet.

Advantages & Value

- Form-fit-function compatibility – Helps extend the life of installed ALSTOM systems with minimal wiring changes.

- Lower outage risk – From my experience, plug-in CPU replacements cut downtime versus full platform migrations.

- Cost-effective lifecycle extension – Delay large CAPEX by stabilizing the existing control layer first.

- Technical matching support – We’ll verify P/N, backplane code, and firmware level to avoid surprises.

- Proven reliability – Rugged board design for 24/7 operation in industrial cabinets.

Installation & Maintenance

- Cabinet environment: Mount in a clean, ventilated 19″ control cabinet; maintain airflow around the rack; avoid corrosive atmospheres.

- Power and ESD safety: Isolate cabinet power before insertion/removal; use ESD wrist strap; handle by edges only.

- Backplane alignment: Seat the card evenly into guides; do not force connectors; lock levers after full engagement.

- Wiring and labeling: Label all front-panel connections; verify port settings if Ethernet/serial are used for engineering access.

- Firmware practice: Backup the current image and configuration; confirm checksums; maintain revision records after updates.

- Routine service: Quarterly visual checks for connector oxidation and dust; cabinet filter cleaning; run onboard diagnostics and review event logs.

Quality & Certifications

- Compliance: Typically CE; ISO 9001 manufacturing practices. RoHS status may vary by revision/date code.

- Functional testing: Units are function-checked prior to shipment whenever applicable to the specific revision.

- Warranty: 365-day warranty coverage from shipment date.

Supporting Components (Commonly Paired)

To speed up replacements, many clients also source companion modules together. You might consider:

- System power supply module (rack backplane supply, 5 VDC rail).

- Digital and analog I/O cards (24 VDC DI/DO, 4–20 mA AI/AO, RTD/TC input).

- Communication interface cards (serial expansion, Ethernet expansion, where the rack design allows).

- Front-panel cables and keyed connectors matching the original cabinet harness.

Real-World Note

A maintenance lead at a combined-cycle plant told us their ECPU_1 swap cut a planned 12-hour outage down to a single shift because the module was a direct drop-in. The only tweak they needed was restoring the saved firmware image and confirming the serial port parameters for the engineering laptop—straightforward, but it saved them a night shift.

If you’re matching by part number, share the exact front panel photo and any backplane code you have. It seems to be the easiest way to confirm whether N895600512D, N895600051C, or N895600200Q is the best fit for your rack revision.

Reviews

There are no reviews yet.