Description

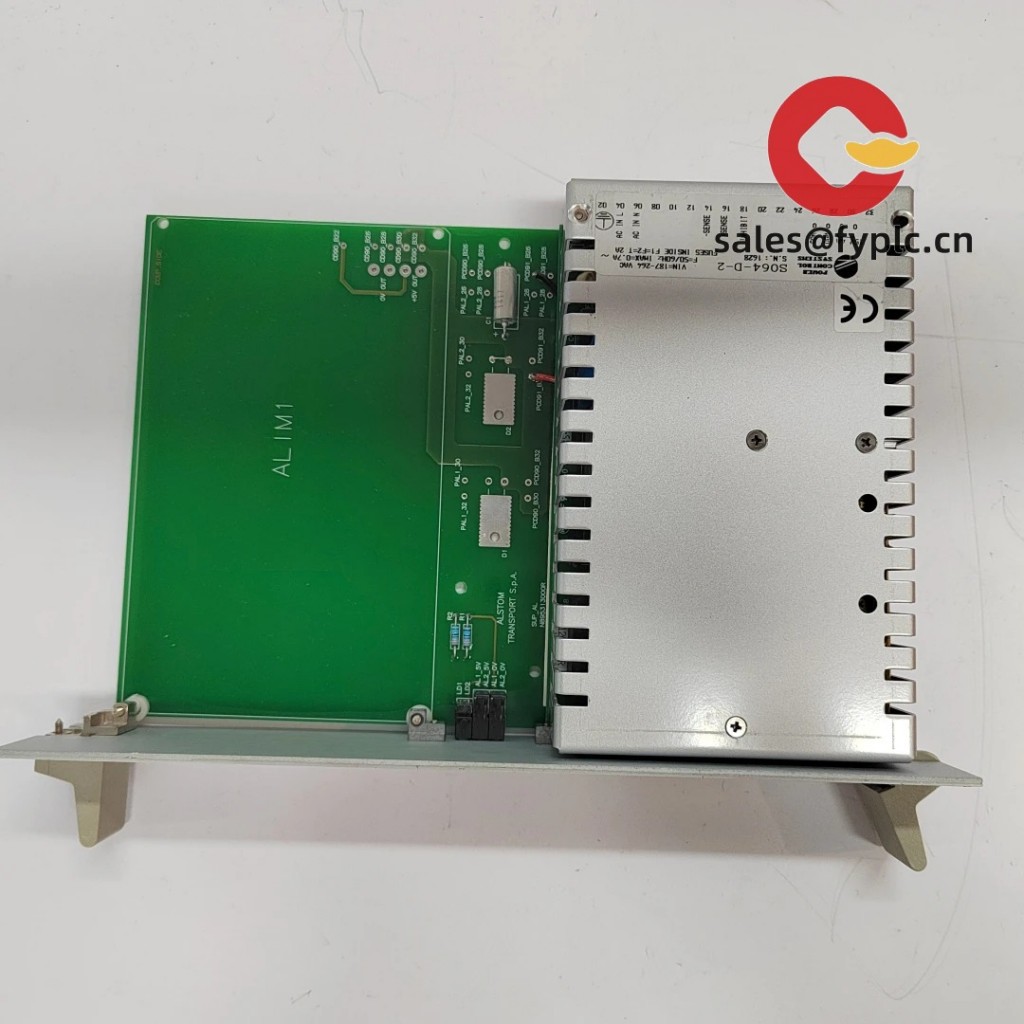

ALSTOM MVUA11B1BD0784B – Plug‑in Control Module for MVU Rack Systems

The ALSTOM MVUA11B1BD0784B is a rack-mounted, plug‑in module from the legacy MVU family, used across industrial control and protection panels where Alstom platforms are installed. From my experience, this module is typically specified as a like‑for‑like replacement board, helping sites keep mature control systems online without re‑engineering the cabinet or re‑terminating field wiring. You might notice that it slots directly into the existing MVU subrack, draws power via the backplane, and works with the original backplane signaling—exactly what maintenance teams need during fast turnarounds.

Our Order Process and Guarantees

- Warranty: 365 days coverage

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

- Functional test and ESD-safe packaging prior to dispatch

Key Features

- MVU-series plug‑in compatibility – Slides straight into the matching Alstom MVU subrack; no external PSU required.

- Backplane powered and signaled – Power and I/O are handled through the host backplane, which keeps field wiring untouched.

- Service-friendly faceplate – Front handle and captive screws for quick swap during planned outages.

- Stable operation in cabinet environments – Typically suited for control-room panels with controlled temperature and ventilation.

- Revision-aware replacement – Labeling supports traceability so you can pair the module revision with your installed firmware set.

- Factory-grade test before shipping – We bench-check core functions to reduce on-site surprises.

Technical Specifications

| Brand / Model | ALSTOM / MVUA11B1BD0784B |

| Product Type | Rack plug‑in control module (MVU series) |

| HS Code | 853890 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | Supplied via host backplane; rack control supply typically DC (commonly 24–48 VDC at system level) |

| Dimensions & Weight | Compact plug‑in module with front faceplate; lightweight board-level assembly suitable for standard control cabinets |

| Operating Temperature | Typically 0 to +55 °C in ventilated cabinet environments |

| Signal I/O Types | Low-voltage logic/analog via backplane; no field power switching on the module face |

| Communication Interfaces | Proprietary MVU backplane interface; external field comms handled at system level |

| Installation Method | Slide-in to Alstom MVU subrack; secure with front screws; ESD-safe handling |

Application Fields

In many cases, the MVUA11B1BD0784B shows up in brownfield projects where the Alstom MVU platform remains central to the process. Typical scenarios include:

- Power generation – Turbine or generator control racks using MVU-series electronics.

- Substation panels – Legacy protection and control cabinets originally supplied by Alstom.

- Rail traction power – MVU-based control equipment in traction substations and wayside cabinets.

- OEM equipment – Skids and packaged systems that embedded MVU control modules during original build.

One thing I appreciate is how these modules keep outage windows short—teams can swap the board, run commissioning checks, and restore service without redesigning the panel.

Advantages & Value

- Drop‑in replacement – Maintains wiring and cabinet layout; reduces integration risk.

- Lower lifecycle cost – Extends the useful life of existing MVU cabinets without a full platform migration.

- Reliability focus – Bench-tested prior to shipment; packaged for shock and ESD protection.

- Compatibility support – We help verify revision fit with your installed rack to avoid mismatches.

- Logistics you can plan around – Short lead times and major express couriers.

Installation & Maintenance

- Cabinet environment – Use a clean, dry, ventilated panel (typically 0–55 °C). Avoid condensation and vibration where possible.

- Power down – Isolate the rack supply before inserting/removing modules; observe lockout/tagout as per site rules.

- ESD handling – Wear a grounded wrist strap; handle by the faceplate and edges only.

- Seating – Insert evenly until the backplane connector is fully engaged; fasten the front screws finger‑tight then snug.

- Wiring – Field terminations usually remain unchanged because all I/O is on the rack backplane.

- Routine care – Periodically clean dust with dry air; inspect connector pins; verify firmware compatibility when swapping revisions; schedule functional checks during outages.

A maintenance manager told us a recent swap “took under 30 minutes from power-down to diagnostic pass,” which seems to be the norm when the rack is in good condition.

Quality & Certifications

- CE conformity typical for industrial control equipment of this class

- Manufacturing quality systems: ISO 9001 at the original production site

- RoHS status may vary by production year for legacy modules

- Warranty: 365 days (repair/replace policy)

Related and Supporting Components

- MVU subrack/backplane assemblies – Host chassis that provide power and signaling to MVU modules.

- Rack DC power supplies – System-level DC feeds (commonly 24–48 VDC depending on installation).

- Front extraction tools and captive screws – For safe, repeatable module removal and insertion.

- Backplane harnessing and ribbon interconnects – Replacement looms if original connectors show wear.

If you can share your rack part number, installed firmware level, or a photo of the nameplate, we can double‑check revision compatibility before you place the order. That small step typically avoids commissioning delays.

Reviews

There are no reviews yet.