Description

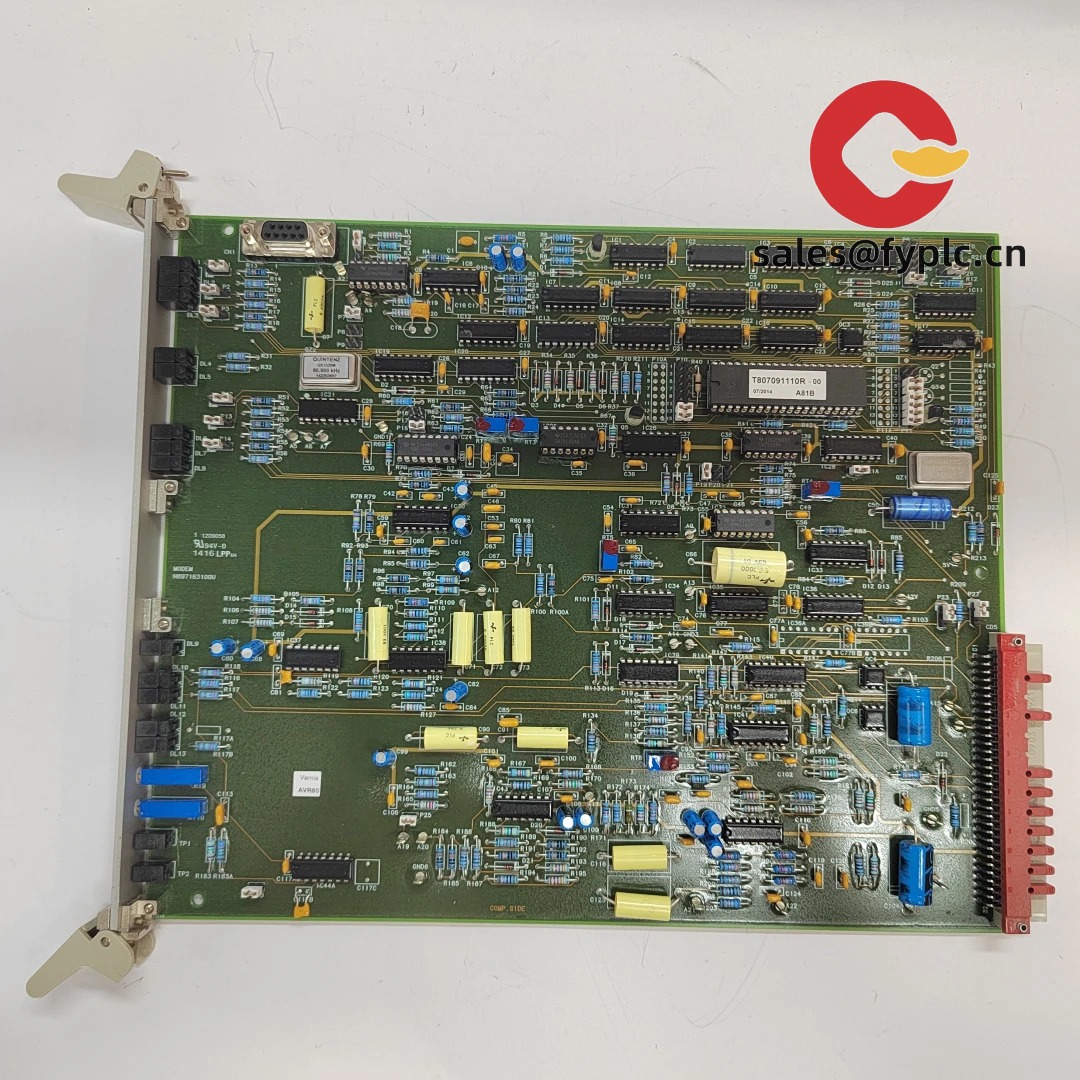

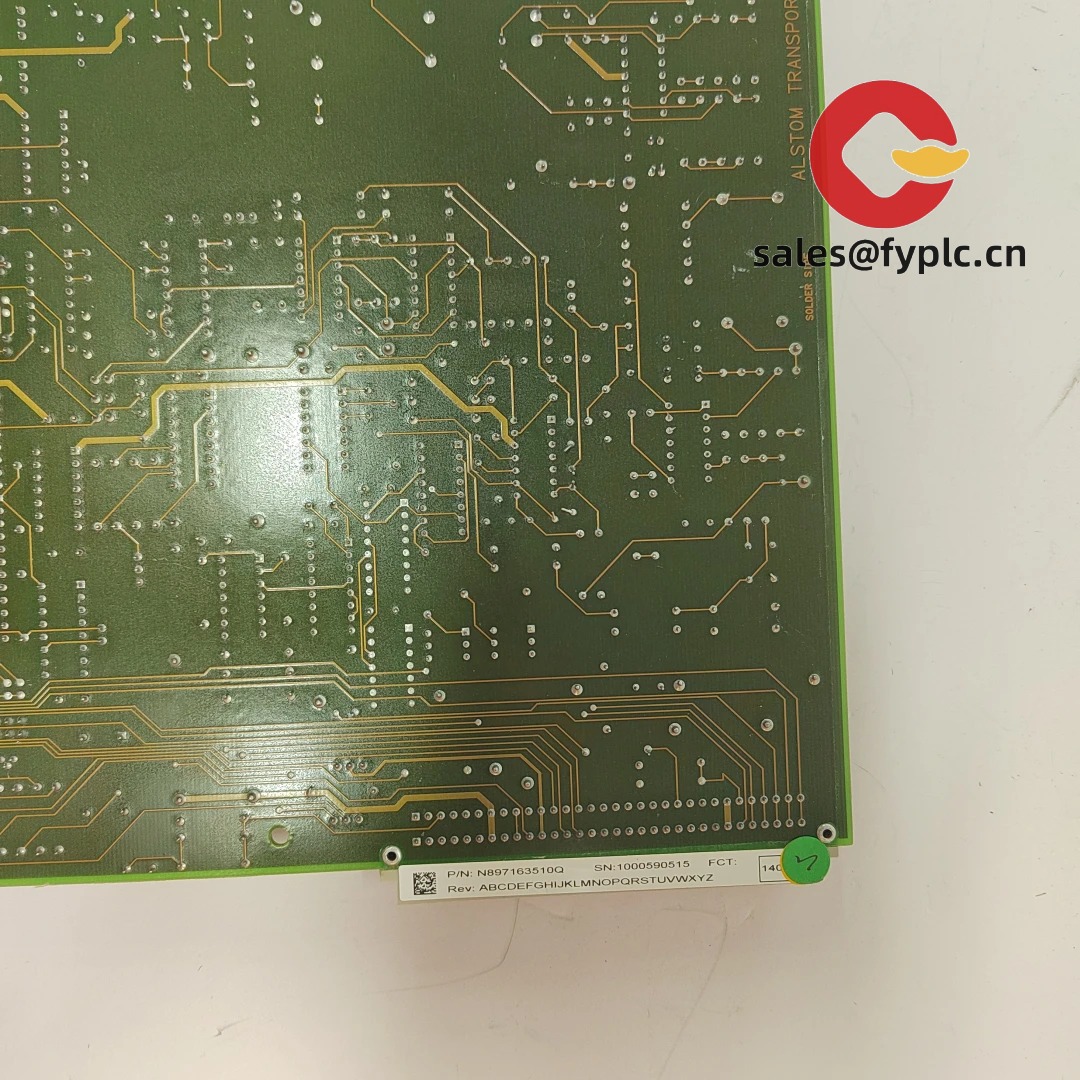

ALSTOM N897163510Q / N897163050Q / N897163100U Modem – Reliable data link modules for signaling and industrial control

These ALSTOM modem modules are widely used as drop-in communication elements inside railway signaling and industrial control cabinets. From my experience, they’re chosen when teams need stable, low-latency data links for interlocking networks, remote I/O, and condition monitoring, without re-architecting legacy systems. You might notice that the three part numbers represent close variants of the same function; the exact interface set and firmware typically differ by cabinet build or project release.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days (bench-tested before dispatch)

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full balance before delivery

- Express carriers: FedEx, UPS, DHL

Key Features

- Designed for signaling cabinets – Stable operation in control rooms and wayside enclosures, typically on 24 VDC supply.

- Legacy-friendly serial connectivity – Commonly supports RS‑232/RS‑485 for interlocking and SCADA integrations.

- Variant alignment – N897163510Q, N897163050Q, and N897163100U align with project-specific builds, easing one-for-one replacement.

- Serviceability in the field – Front-access connectors and status LEDs in most builds make commissioning and fault tracing faster.

- Robust EMC behavior – Built for electrically noisy sites; typically paired with shielded cabling and surge protection.

- Stable, deterministic links – Suits low-bandwidth but safety-relevant traffic where consistency matters more than peak throughput.

Technical Specifications

| Brand / Model | ALSTOM – N897163510Q / N897163050Q / N897163100U (industrial modem module) |

| HS Code | 8517.62.00 (Data transmission equipment) |

| Power Requirements | 24 VDC nominal; wide-range DC inputs are common (often 18–36 VDC in many builds) |

| Operating Temperature | Typically −25 °C to +70 °C for wayside/control room environments |

| Signal Input/Output Types | Serial interfaces commonly RS‑232 and/or RS‑485; status LEDs and service port depending on variant |

| Communication Interfaces | Point‑to‑point or multi‑drop serial modem operation; some cabinets include an associated Ethernet bridge |

| Installation Method | DIN‑rail or panel mounting inside protected control cabinets; front-access connectors are typical |

| Dimensions & Weight | Compact module form factor (approx. 120 × 100 × 35 mm; ~0.4 kg, varies by variant) |

Application Fields

- Signaling interlockings and control cabinets (wayside and central rooms)

- Remote I/O backhaul for trackside equipment (point machines, signals, TPWS/ATP)

- Depot and station SCADA data links (alarms, metering, environment monitoring)

- Condition-based maintenance links for legacy subsystems where Ethernet isn’t native

Advantages & Value

- Low-risk replacement – Direct fit for existing ALSTOM-built panels, reducing retesting and requalification effort.

- Compatibility first – Keeps serial protocols and wiring intact, which typically avoids interface converters.

- Reduced downtime – Pre-tested units help maintenance teams turn repairs quickly during night possessions.

- Lifecycle support – We help match the exact variant (e.g., N897163510Q vs N897163100U) by cabinet BOM and photos.

- Cost control – Extends asset life without wholesale migration to new network architecture.

Installation & Maintenance

- Cabinet environment: Install in a sealed control cabinet with adequate ventilation; keep ambient within specified range.

- Power & grounding: 24 VDC supply with correct polarity; bond shields at one end; implement cabinet earth per site standard.

- Wiring: Use shielded twisted pairs for serial/line connections; maintain separation from power cables to minimize noise.

- Surge protection: In most cases a series surge arrester on field lines is recommended for lightning-prone routes.

- Commissioning: Record DIP/parameter settings; verify link using loopback or built‑in test LEDs before handover.

- Routine maintenance: Quarterly connector inspection and dust cleaning; annual link test; keep a backup of parameters/firmware where applicable.

- Spares practice: Many teams keep 10–15% spares on critical corridors; seems to reduce mean time to restore significantly.

Quality & Certifications

- CE compliance and RoHS alignment typical for control-cabinet electronics

- EMC for railway installations often aligned to EN 50121 series (project dependent)

- Manufacturing quality systems generally aligned with ISO 9001

- Manufacturer’s warranty support: 12 months

Recommended Supporting Components

- 24 VDC DIN‑rail power supply (industrial grade, with brown‑out ride‑through)

- Surge protectors for line and serial ports (railway-rated, fast clamping)

- Shielded serial cables (RS‑232/RS‑485) with proper pinout per cabinet drawing

- DIN‑rail Ethernet switch (if bridging to IP networks is required in the cabinet)

From a recent depot team: “Swapping the N897163050Q was straightforward—same connectors and settings as the old unit. Link came up on first power, so we finished within the blockade.” That’s typically what we aim for: predictable behavior and minimal rework.

Reviews

There are no reviews yet.