Description

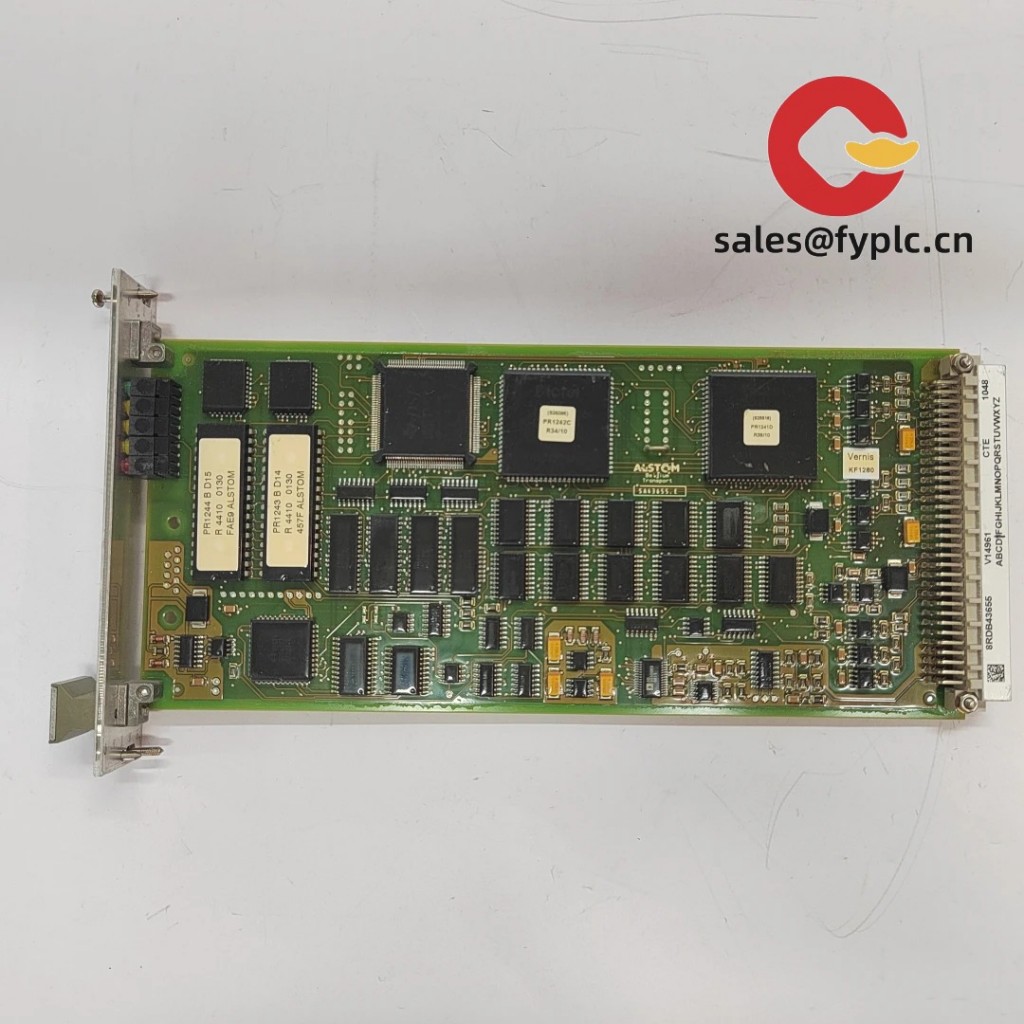

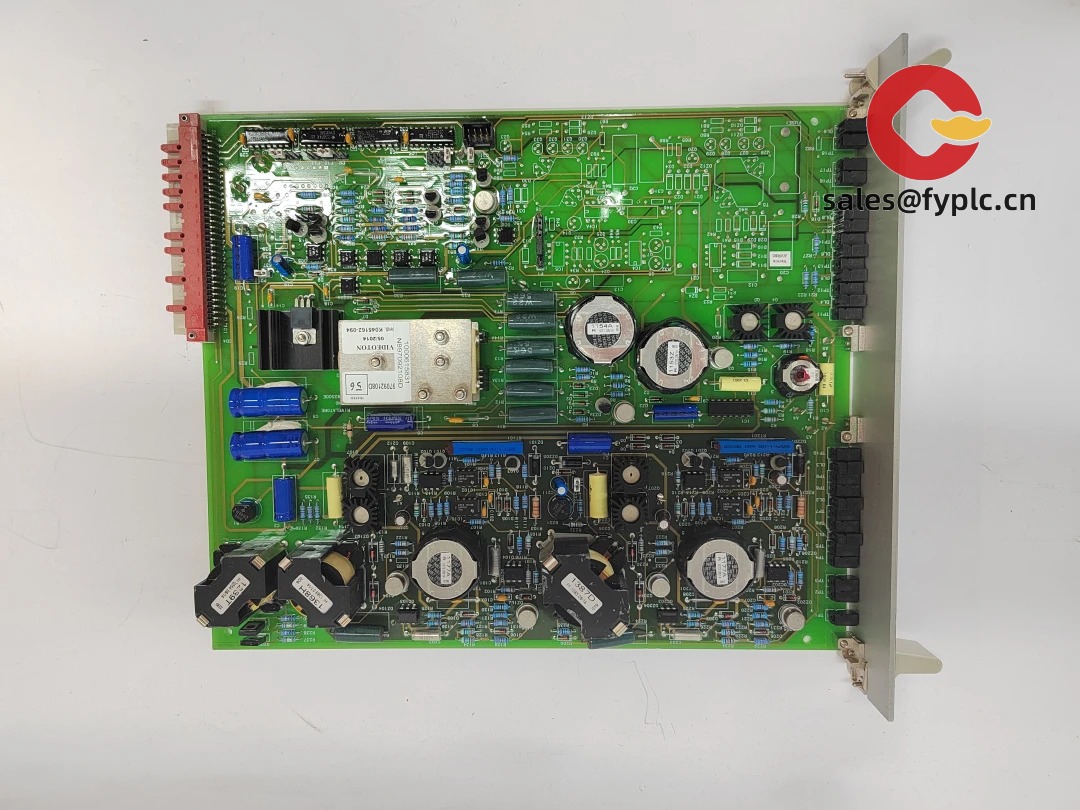

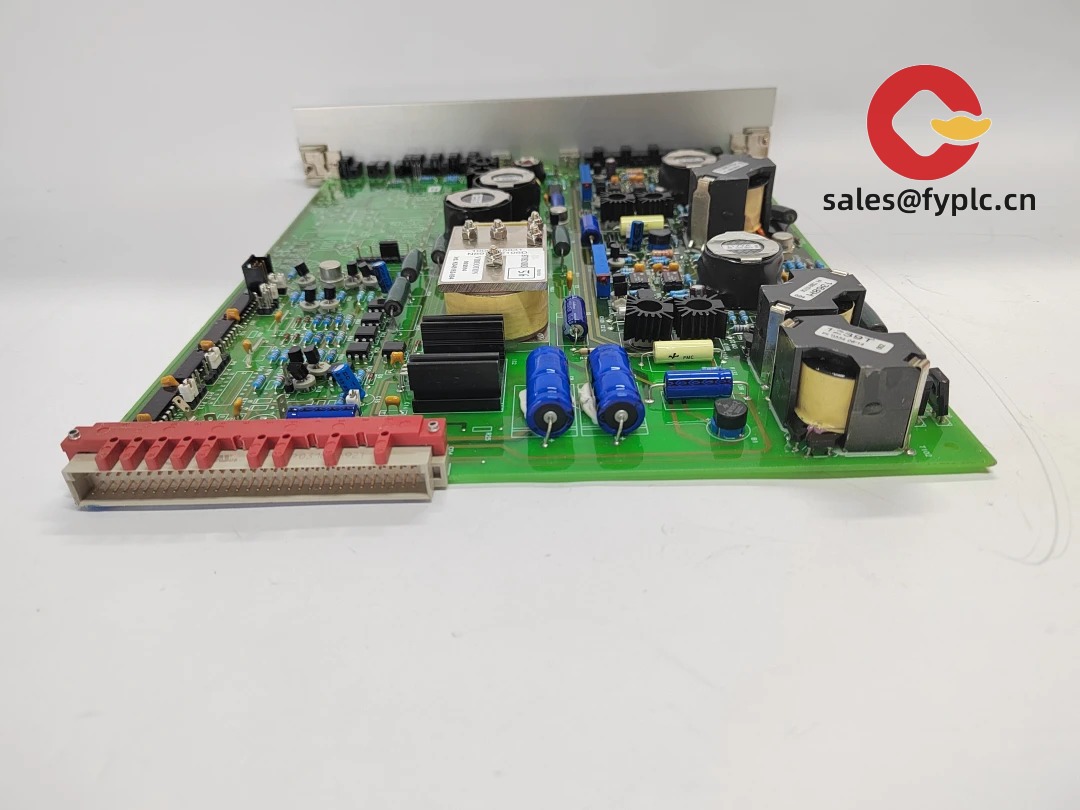

ALSTOM N897092520B / N897092057Y / N897092500E (TRENO) – Train TCMS I/O and Control Modules for Rolling Stock Maintenance

From my experience supporting mid-life overhauls, these ALSTOM N8970-series modules are typically used as plug-in control and I/O boards inside onboard racks tied to the TCMS.

The three codes here—N897092520B, N897092057Y, and N897092500E (TRENO)—appear to be closely related variants used across different fleets, with suffixes indicating hardware/firmware revisions or I/O map differences.

You might notice that they’re favored as form-fit-function spares: drop the card in, connect the harness, and the train is back in service without re-engineering.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- TCMS-ready integration: Designed for onboard control racks; commonly interfaces with vehicle buses used in ALSTOM fleets.

- Railway-grade power: 24 VDC nominal input with robust transient protection for rolling stock power environments.

- Ruggedized electronics: Shock/vibration tolerant construction suitable for underframe or saloon equipment cabinets.

- Isolated I/O: Discrete 24 VDC inputs/outputs and, in many cases, analog channels for auxiliary systems.

- Form-fit-function spares: A practical drop-in replacement to shorten downtime during corrective maintenance.

- Traceable part IDs: Clear part markings for configuration control; suffixes (B/Y/E) indicate revision or variant.

Technical Specifications

Specifications below reflect typical characteristics for this ALSTOM N8970-series of onboard I/O/control modules. Exact I/O maps and bus options can vary by vehicle program; we can verify against your train data sheet or a photo of the module label.

| Brand / Models | ALSTOM N897092520B / N897092057Y / N897092500E (TRENO) |

| HS Code | 853890 (Parts suitable for use with electrical control equipment) |

| Power Requirements | 24 VDC nominal (typical operating range 16.8–30 VDC), input protection against transients and reverse polarity |

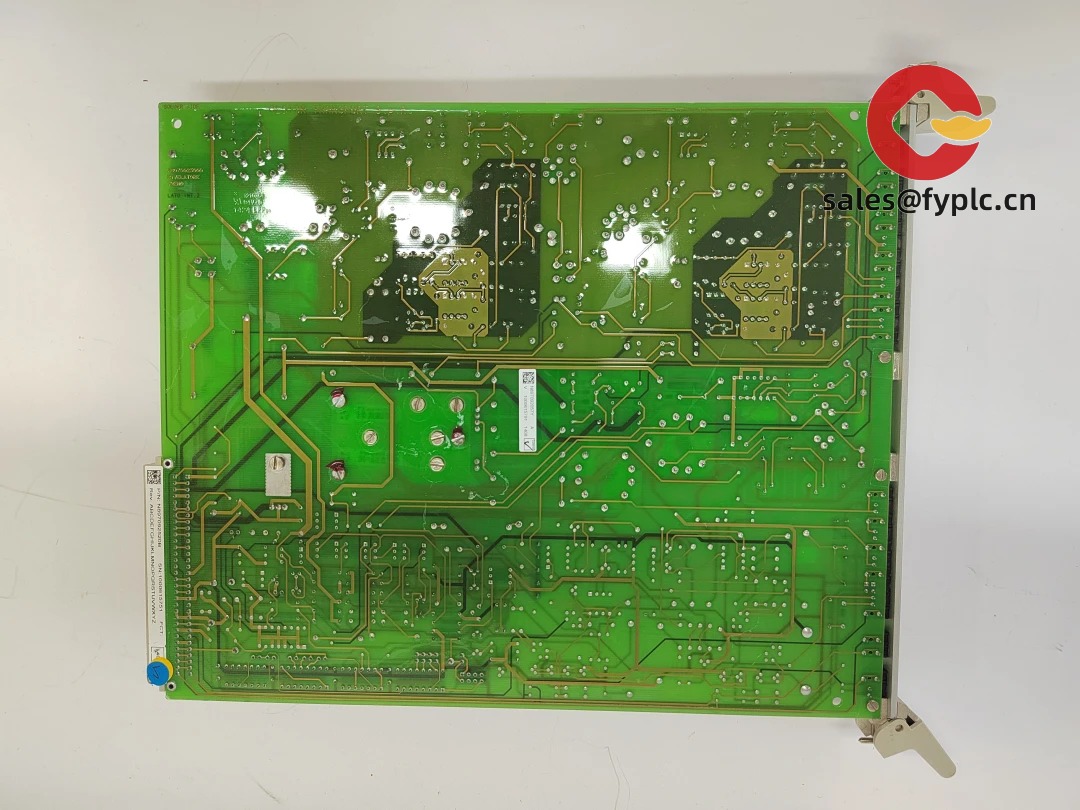

| Dimensions & Weight | Plug-in rack module; commonly 3U format with approx. 220–260 mm card depth; weight typically under 1.2 kg (varies by variant) |

| Operating Temperature | -25 °C to +70 °C (railway onboard environment; storage range wider) |

| Signal I/O Types | Discrete 24 VDC inputs/outputs (sink/source); some variants with analog 0–10 V or 4–20 mA channels; galvanic isolation on selected channels |

| Communication Interfaces | Vehicle bus interface as specified by fleet (commonly MVB or serial RS‑485 service access); model-specific connectors |

| Installation Method | Rack-mounted plug-in module with backplane connector; front-panel D‑sub / circular or spring-clamp interfaces depending on variant |

Application Fields

These modules are suited to onboard subsystems typically managed by the TCMS, including:

- Door control and interlock I/O

- HVAC command/feedback and fan group control

- Auxiliary converters and battery charger supervision

- Lighting, PIS/CCTV trigger lines, and cab signals interfacing

- Bogie/axlebox condition inputs and event/alarm aggregation

A rolling stock operator in Italy shared that the N8970-series card made a same-day recovery possible on a commuter set—swap the card, reload configuration, and the consist was cleared for service before the evening peak. That’s typically the kind of turnaround these parts are bought for.

Advantages & Value

- Reliability in service: Built for the electrical noise and vibration found on trains, with stable performance over long duty cycles.

- Compatibility: Form, fit, and function alignment with existing ALSTOM racks reduces commissioning risk.

- Cost savings: Shorter downtime and no redesign of wiring or software typically means lower total maintenance cost.

- Technical support: We can match module suffixes and firmware levels against your train’s BOM to avoid version conflicts.

Installation & Maintenance

- Cabinet standards: Mount in the designated onboard rack; keep 20–30 mm clearance for ventilation and cable bend radius.

- Power & grounding: Use a clean 24 VDC supply with proper earthing; verify polarity and chassis bonding to avoid ground loops.

- Wiring: Match I/O channel numbering to the original card; confirm discrete input thresholds and output load limits before energizing.

- Addressing/configuration: Set DIP/rotary addresses as per the original; reload configuration files if the fleet requires parameterization.

- Safety: De-energize circuits, observe ESD precautions, and document the card’s serial/revision during swap.

- Routine care: Quarterly dusting with dry air, connector inspection, and—where applicable—firmware/parameter verification after major overhauls.

Quality & Certifications

- Designed for rail environments in line with EN 50155 and EN 50121 practices (model- and project-dependent)

- CE marking and RoHS conformity are commonly applied on this category of onboard electronics

- Manufactured under ISO 9001 quality systems (typical for ALSTOM supply chains)

- Warranty: 365 days from shipment

Recommended Supporting Components

- 24 VDC isolated PSU (rail grade): To stabilize onboard supply during cranking and transient events.

- Backplane / rack slot hardware: Replacement card guides and ejector hardware for worn cabinets.

- MVB harness or serial service cable: For commissioning and diagnostics.

- Shielded I/O jumpers: Reduce induced noise on long runs to door or HVAC subsystems.

If you can share a photo of the module’s front panel and nameplate (including the full code with suffix), we can confirm the exact variant—N897092520B, N897092057Y, or N897092500E (TRENO)—and match the I/O map and firmware expectations for your fleet. That small step usually prevents compatibility surprises.

Reviews

There are no reviews yet.