Description

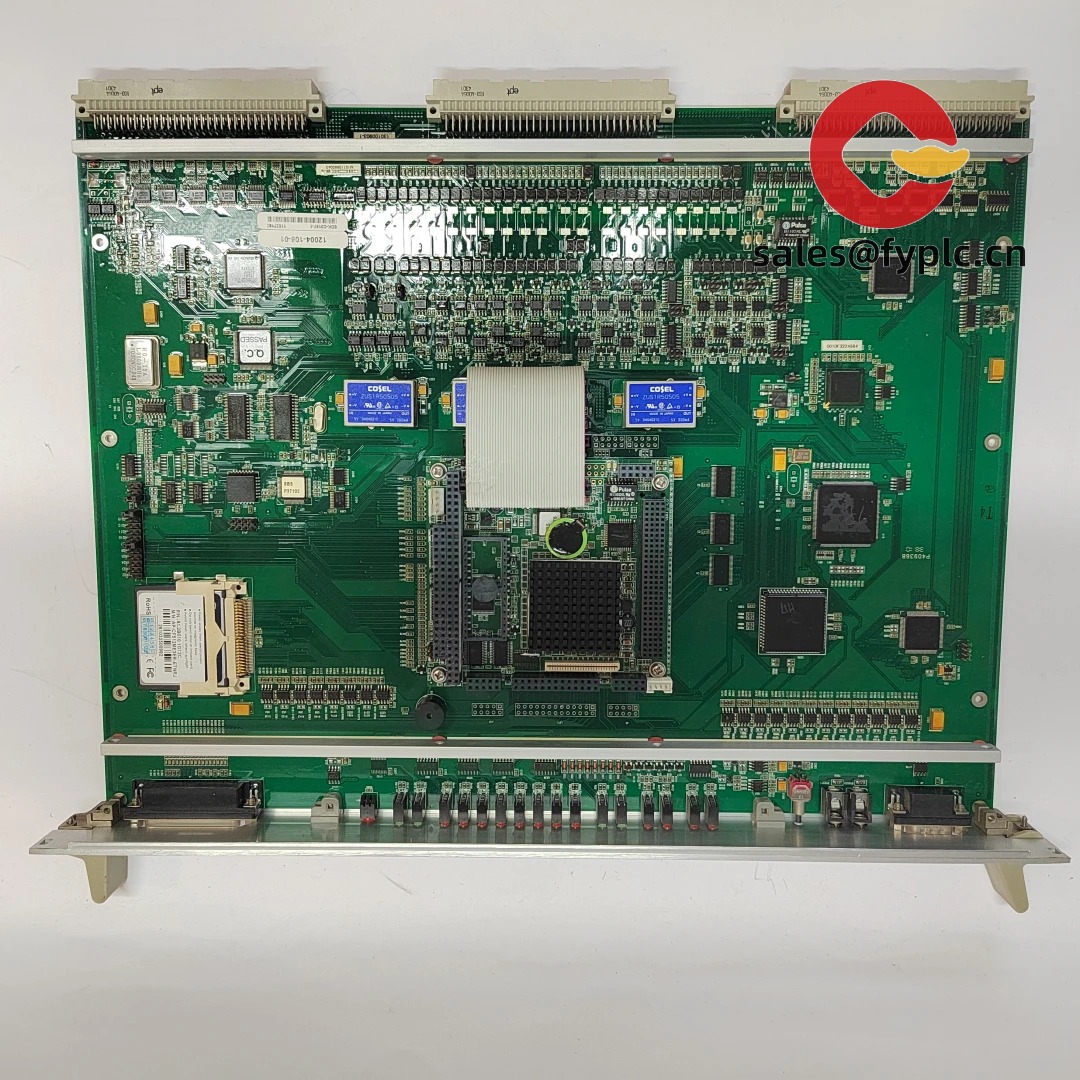

ALSTOM SDK-C0167-1 12004-08-01 SBS07M076B – Plug‑in Control Board for Rail Signaling and Industrial Cabinets

From my experience, the ALSTOM SDK-C0167-1 12004-08-01 SBS07M076B is best understood as a field-proven, plug‑in control/processing board used in ALSTOM signaling and protection cabinets. You might notice the three identifiers together: “SDK-C0167-1” typically points to the hardware board, “12004-08-01” reflects a production or revision code, and “SBS07M076B” seems to be a software or variant reference. In practice, this combination helps maintenance teams match the exact spare against installed bases, so swaps are fast and low-risk.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Drop‑in replacement for ALSTOM racks – Designed as a plug‑in module to minimize cabinet rework and downtime.

- Stable 24 VDC control power – Typically powered from the cabinet’s 24 VDC bus with generous noise immunity for rail environments.

- Backplane bus compatibility – Interfaces via the system backplane; front connectors support I/O as required by the application.

- Status and diagnostics – In many cases, onboard indicators and self‑checks help technicians verify health at a glance.

- Industrial temperature performance – Built for cabinets where ambient conditions vary, typically meeting rail/industrial ranges.

- Serviceable design – Field‑replaceable with guide rails and captive fasteners that make swaps straightforward.

Technical Specifications

| Brand / Model | ALSTOM SDK-C0167-1 / 12004-08-01 / SBS07M076B |

| HS Code | 8537.10 – Boards/panels for electric control (≤1000V), typical classification for control modules |

| Power Requirements | 24 VDC nominal (18–36 VDC typical in many cabinets) |

| Dimensions & Weight | Approx. 3U plug‑in board (Eurocard‑style ~100 × 160 mm); weight typically < 0.5 kg |

| Operating Temperature | Typically −20 °C to +55 °C (cabinet‑mounted; verify per installed system spec) |

| Signal I/O Types | Backplane bus I/O; front multi‑pin connectors for digital/analog signals depending on variant |

| Communication Interfaces | Proprietary backplane interface; RS‑485/CAN are used in many ALSTOM cabinets |

| Installation Method | Plug‑in module for ALSTOM system rack/backplane; guided insertion with captive screws |

Notes: Exact I/O mix and firmware functions depend on the specific cabinet configuration. The above values reflect common practice for this series.

Application Fields

- Rail signaling interlocking cabinets and wayside control points

- Traction power and protection panels in substations

- On‑board control or auxiliary systems where ALSTOM rack modules are specified

- Industrial automation cabinets requiring ALSTOM‑compatible control boards

One thing I appreciate is how easily it integrates into mixed fleets. A maintenance manager at a metro operator told us the swap took under 15 minutes, then the board passed loop‑back checks on the first try, which isn’t always the case with legacy gear.

Advantages & Value

- Reduced downtime – Plug‑in form factor and consistent pinout help speed up field replacement.

- Compatibility – Matches ALSTOM rack/backplane conventions, avoiding ad‑hoc rewiring.

- Lifecycle support – Suitable as a long‑term spare for installed bases where redesigns are costly.

- Quality assurance – Each unit is function‑checked prior to dispatch, which in many cases cuts commissioning time.

- Total cost control – Predictable lead times and a solid warranty reduce unplanned service costs.

Installation & Maintenance

- Cabinet requirements – Install in a dry, ventilated 19‑inch cabinet; keep ambient within the system’s specified temperature band.

- Power and grounding – Use a stable 24 VDC supply with proper protective earth; segregate I/O and power wiring to reduce noise.

- Mechanical seating – Align with guide rails, insert evenly, and secure captive screws; do not force the connector into the backplane.

- Safety – De‑energize the cabinet and observe ESD precautions before handling the module.

- Routine maintenance – Quarterly dust removal with dry air, visual inspection of connectors, and verify firmware/config backups where applicable.

- Calibration/updates – If the application uses analog channels or logged parameters, schedule annual checks; apply approved firmware only.

Quality & Certifications

- CE conformity and EMC compliance applicable to control cabinets

- RoHS compliance for restricted substances (where applicable)

- Manufactured under ISO 9001 quality management systems

- Warranty: 365 days (replacement or repair subject to evaluation)

Recommended Supporting Components

- ALSTOM backplane/rack compatible with SDK‑series plug‑in boards

- 24 VDC regulated power supply with surge protection (rail‑grade, if used trackside)

- Shielded multi‑pin front cables and labeled harnesses for quick diagnostics

- ESD‑safe handling kit and guided insertion rails for service teams

If you’re matching a specific cabinet bill of materials, share your installed part label photo or a configuration snapshot; we’ll cross‑check the “SDK‑C0167‑1 / 12004‑08‑01 / SBS07M076B” combination against your rack and firmware to confirm pinout and behavior before shipping.

Reviews

There are no reviews yet.