Description

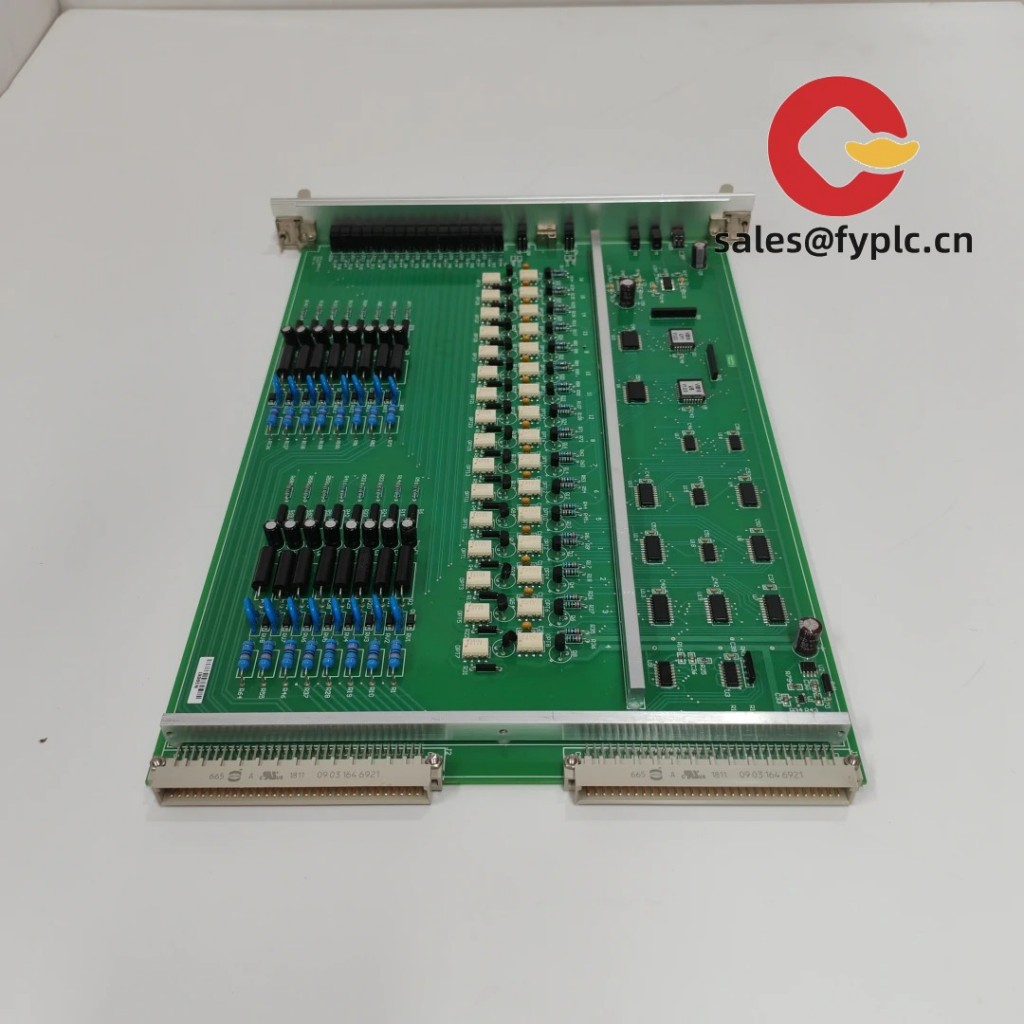

AMAT 0100-71267 – OEM Spare Part Assembly for Applied Materials Semiconductor Tools

The AMAT 0100-71267 is an OEM-grade spare part assembly designed for Applied Materials equipment, supplied as a like-for-like replacement so your tool can return to qualified process quickly. One thing I appreciate is how straightforward it typically is—swap, verify rev level, and bring the chamber back online with minimal recipe disturbance. In many cases, this part is treated as a field-replaceable unit (FRU) and follows the same fit, form, and function as the original BOM callout.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Traceability: Part number and revision recorded; functional test report available on request

Key Features

- OEM-compatible FRU – Delivered as a direct replacement for the specified AMAT BOM position, avoiding requalification work.

- Drop-in fit – Identical connector layout and mounting pattern to the original part, which typically means no wiring or software changes.

- Cleanroom-ready packaging – ESD-safe, moisture-barrier packing to protect sensitive electronics during transport and staging.

- Documented rev control – We confirm part revisions to match your tool’s requirement, reducing mismatch risk.

- Fast turnaround – Practical lead times for tool-down situations; advance replacement can be arranged in many cases.

- 365-day coverage – Warranty support that gives maintenance teams confidence when planning PMs and unscheduled repairs.

Technical Specifications

| Brand / Model | Applied Materials (AMAT) / 0100-71267 |

| HS Code | 8486.90 – Parts for semiconductor manufacturing equipment |

| Part Category | OEM spare part assembly (direct replacement FRU) |

| Power Requirements | Supplied by host system; no separate external power connection required |

| Operating Environment | Cleanroom fab environment; typically 15–35°C ambient, 20–80% RH non‑condensing |

| Signal/Interface | Matches original OEM connectors and pinout; no tool software changes expected |

| Installation Method | Like-for-like replacement per AMAT maintenance manual; ESD-controlled handling |

| Packaging | ESD-safe moisture barrier bag, foam-cushioned, labeled with P/N and rev |

Application Fields

Used as a replacement part within Applied Materials process tools across wafer fabrication lines—typical scenarios include restoring functionality after interlock trips, intermittent I/O faults, or suspected board-level failures. From my experience, maintenance teams install parts like 0100‑71267 during chamber PMs or when troubleshooting uptime issues in PVD, CVD, etch, or implant modules where the BOM calls out this specific number.

Advantages & Value

- Risk reduction – Correct P/N with rev verification lowers the chance of downtime from mismatch.

- Cost control – Like-for-like replacement avoids additional requalification expense and preserves tool recipes.

- Compatibility assurance – Delivered to the original interface spec; no unexpected connector or firmware surprises.

- Documented QA – Incoming and outgoing checks; functional testing available upon request.

- Service support – Help with cross-checking revisions and confirming interchangeability before you place the order.

A process engineer at a 200 mm fab told us a recent swap took about 30 minutes door-to-door, and the tool cleared alarms immediately after reseating and power cycling. That seems to be the norm when the part and rev match the tool config.

Installation & Maintenance

- Follow AMAT service procedures; power down, lockout/tagout as required by site policy.

- Use ESD protection (wrist strap, grounded mat); handle by edges to avoid component stress.

- Verify part number and revision against the tool’s parts list before installation.

- Inspect connectors for bent pins; ensure clean seating and proper torque on any fasteners.

- Post-install: run the tool’s diagnostics; clear faults and confirm interlocks and I/O status.

- Routine care: periodic visual checks during PM; if firmware applies, align versions to the tool baseline.

Quality & Certifications

- Conforms to OEM manufacturing and fab EHS handling practices

- CE/UL: equipment-level compliance maintained when installed in the original system

- RoHS: supplied per OEM status for the specified revision

- Quality process: shipment and handling under ISO 9001-style controls

- Warranty: 365 days from shipment

How to Order

Share your tool model, chamber, and current part revision for AMAT 0100-71267. We’ll confirm compatibility, quote lead time, and lock the unit for you. For urgent tool-downs, you might request photos of labels and a quick functional report—this usually speeds internal approval on your side.

Reviews

There are no reviews yet.