Description

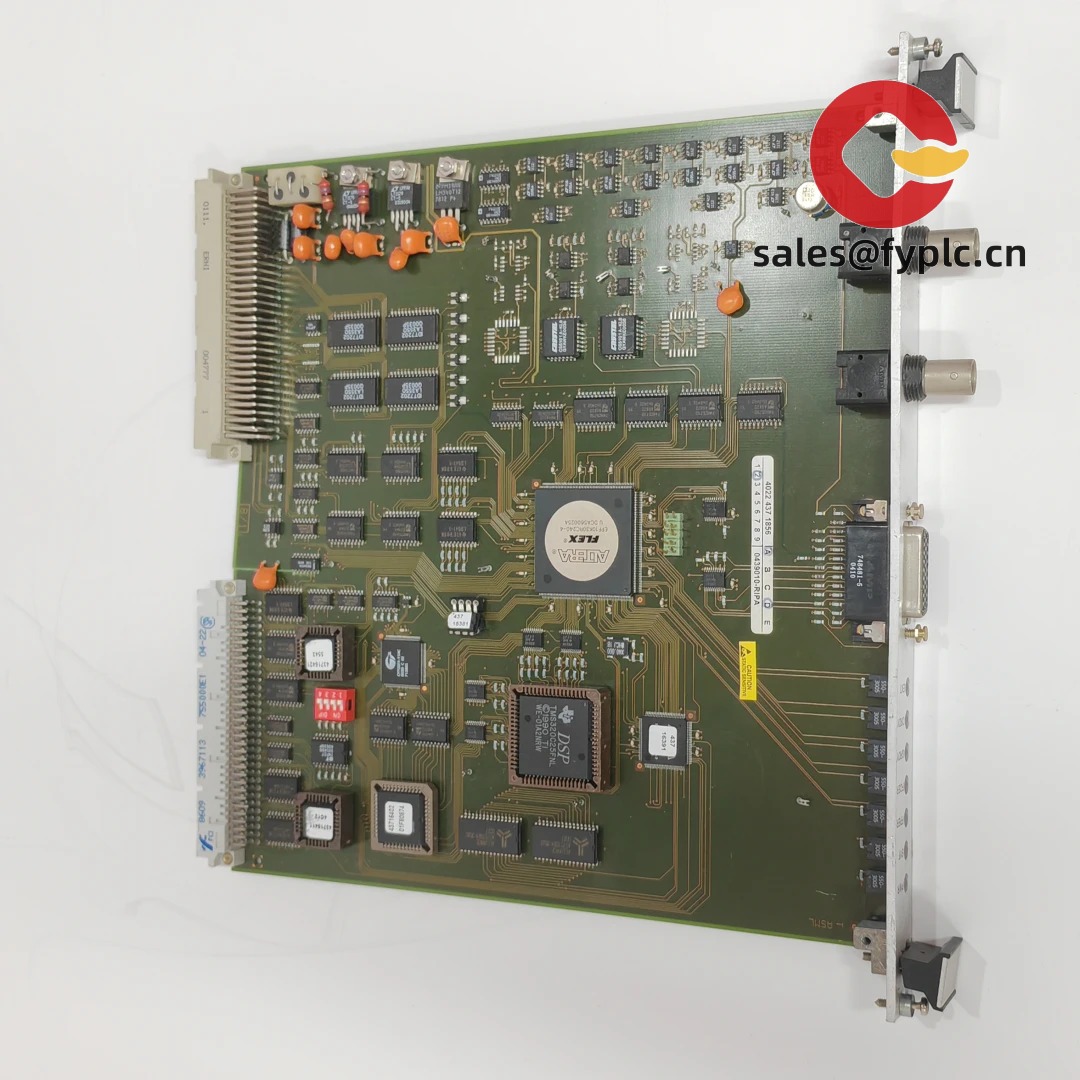

ASML MC1AB37 (4022.437.1856) – Control Module for Precision Mechatronics in Lithography Systems

The ASML MC1AB37, part number 4022.437.1856, is an OEM control module used within ASML lithography platforms to coordinate high‑precision motion and related I/O at the subsystem level. From my experience, modules in the MC1 family typically handle deterministic control tasks for stages, actuators, and sensor loops, leveraging the system backplane for power and communications. If you’re maintaining uptime on a scanner or stepper, this is the kind of board you keep on the shelf for fast swap and minimal recalibration.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- OEM-original module – Built for ASML tools, ensuring mechanical fit and firmware compatibility with existing cabinets.

- Deterministic control – Typically used for motion and synchronized I/O where microsecond-level timing stability matters.

- Backplane-powered – 24 VDC system supply in most cases, simplifying cabinet wiring and reducing external power complexity.

- Serviceable design – Slide-in installation supports quick swap to cut MTTR during field service.

- ESD- and transit-safe packaging – Anti-static bag and cushioning to help protect sensitive components.

- Traceability – Clear part/model identification (MC1AB37 / 4022.437.1856) for maintenance records and configuration control.

- Stable lifecycle support – From my experience, firmware-matched replacements reduce requalification time after changeout.

Technical Specifications

| Brand / Model | ASML MC1AB37 (P/N 4022.437.1856) |

| HS Code | 8486.90 (Parts and accessories for semiconductor manufacturing equipment) |

| Power Requirements | 24 VDC nominal from system backplane (typical for ASML cabinet modules) |

| Operating Temperature | 0 to 50°C, non‑condensing environment inside tool cabinet (typical) |

| Signal I/O Types | Deterministic control I/O via internal connectors; 24 V digital I/O commonly used; motion/feedback interfaces as per tool configuration |

| Communication Interfaces | ASML system backplane; service interface availability depends on revision and tool generation |

| Installation Method | Slide-in module for ASML cabinet/card frame; secured with front fasteners; ESD-safe handling required |

| Dimensions & Weight | Compact cabinet module; fits designated ASML slot; weight typically under 1.5 kg |

Application Fields

This module is suited for ASML lithography systems where precise mechatronic control is required—wafer stage positioning, reticle handling, or auxiliary motion subsystems. You might notice that using an MC1-series module as a like-for-like replacement keeps control loops stable and typically avoids long re-tuning sessions. Many customers deploy it during preventive maintenance windows to refresh high‑duty control paths with minimal downtime.

Advantages & Value

- Reliability – OEM spec hardware tends to maintain lock-step behavior with existing firmware, reducing integration risk.

- Compatibility – Form-fit-function alignment with ASML card frames and harnessing keeps field work predictable.

- Cost control – Quick swap times and stable calibration typically translate to lower service hours and reduced scrap exposure.

- Support – We can match revision levels on request and coordinate functional testing to your tool configuration.

Installation & Maintenance

- Cabinet environment – Install in the designated ASML slot; ensure cabinet ventilation is unobstructed and filters are clean.

- Power & wiring – Isolate tool power, discharge residual energy, and observe ESD procedures. Verify backplane seating and connector latching.

- Firmware alignment – In many cases, matching firmware/revision avoids requalification. Back up parameters before swap, then validate after boot.

- Functional checks – Run stage/motion self-tests, confirm limit signals, encoder feedback, and interlocks before returning to production.

- Routine care – Keep cabinet dust-free; schedule periodic connector inspections; document any parameter changes for traceability.

Quality & Certifications

- CE conformity when integrated within the certified ASML system (typical for this class of module)

- RoHS-compliant components in most contemporary revisions

- Manufactured under ISO 9001–aligned quality systems at the OEM

- Warranty: 365 days from delivery

Recommended Accessories & Related Parts

- Backplane connector hardware and front-panel fasteners for the designated slot

- ESD-safe handling kit and cabinet air filters for preventive maintenance

- Service cable for diagnostic access (where applicable)

- Matched revision modules for paired motion channels to maintain symmetry

Reviews

There are no reviews yet.