Description

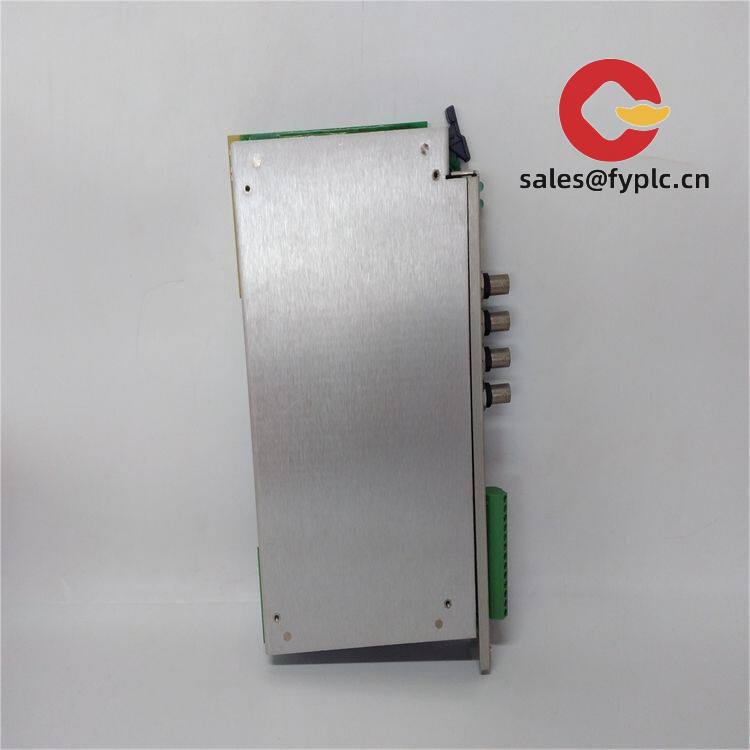

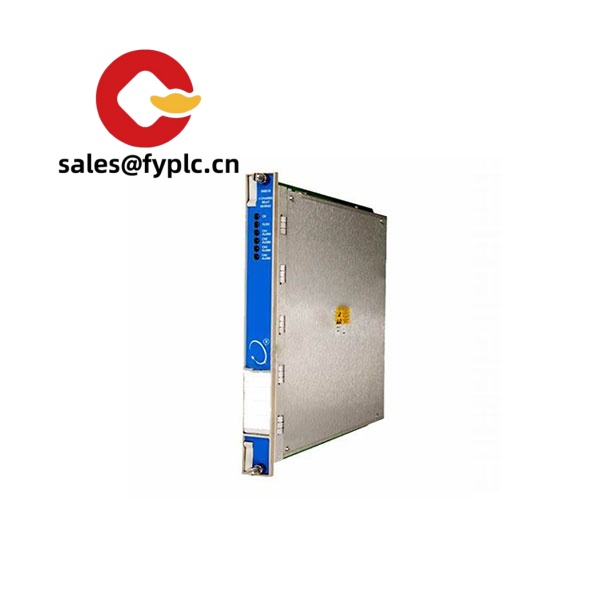

BENTLY NEVADA 125744-01 – 3500 Series Module for Vibration Monitoring and Machine Protection

The BENTLY NEVADA 125744-01 is a module used within the 3500 Series rack to support continuous vibration monitoring and API-compliant machine protection. From my experience, it’s chosen as a dependable field I/O and signal interface point for the paired 3500 monitor card, helping you wire transducers cleanly and keep maintenance quick. You might notice that the modular design typically allows service without disturbing field wiring, which is a real timesaver during outages.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Designed for the 3500 rack – Integrates with 3500 Series monitor modules for continuous vibration and speed monitoring.

- Field-wiring convenience – Typically provides screw-terminal connections and, in many cases, buffered dynamic signal access for diagnostics.

- Separation of I/O and monitor – The rear I/O base keeps plant wiring intact while the front monitor can be serviced or swapped.

- Protection-grade architecture – Works within the 3500 architecture that many plants trust for trip logic, alarms, and API 670 compliance practices.

- Rack backplane power and communication – No external power supply; signals exchange with the system via the 3500 backplane and TDI.

- Installation flexibility – Suited for standard 19-inch 3500 racks in control cabinets alongside DCS/PLC marshalling.

Technical Specifications

| Brand / Model | BENTLY NEVADA 125744-01 (3500 Series module) |

| HS Code | 9031.80 (Measuring/monitoring instruments and devices) |

| Power Requirements | Supplied by the 3500 rack backplane; no separate external power |

| Operating Temperature | Typically 0 to +60°C for control room installations |

| Signal I/O Types | Varies by paired monitor; commonly supports prox/accel dynamic inputs and buffered outputs for diagnostics |

| Communication Interfaces | Internal 3500 backplane; system communications via 3500/22M TDI (not on the I/O module itself) |

| Installation Method | Rear I/O module in a 3500 rack slot; mates with corresponding front monitor for signal processing |

| Dimensions & Weight | Standard 3500 rack form factor; occupies one rear I/O position (compact, panel-depth) |

Application Fields

The 3500 platform is widely used for continuous vibration monitoring on critical rotating assets. The 125744-01 module fits setups where reliability and maintainability matter more than anything else.

- Steam and gas turbines in power generation

- Compressors and expanders in oil & gas midstream/downstream

- Pumps, ID/FD fans, blowers, and gearboxes in chemical plants

- Large motors, generators, and critical HVAC equipment in industrial facilities

A maintenance lead from a refinery recently mentioned that swapping a faulty monitor was “under two hours, wiring untouched,” which seems to be a typical benefit of the 3500 rear I/O design.

Advantages & Value

- Reliability – Proven 3500 ecosystem used in API 670 environments for years.

- Compatibility – Works within the standard 3500 rack with common monitors and the 3500/22M TDI.

- Maintenance efficiency – Separate rear I/O helps reduce downtime during module replacement or calibration.

- Lifecycle cost savings – Spare pooling and modular architecture typically lower total cost of ownership.

- Technical support – Widely supported in the field; documentation and know‑how are readily available.

Installation & Maintenance

- Cabinet & rack – Mount in a standard 3500 rack within a ventilated cabinet; avoid high vibration or moisture in the panel.

- Wiring – Use shielded, twisted pairs for dynamic signals; land shields per manufacturer guidance to minimize noise.

- Grounding – Maintain a clean instrument ground; separate from power ground where required to avoid ground loops.

- ESD & safety – Follow ESD precautions; if replacing modules online, place channels in bypass and follow plant work permits.

- Routine checks – Verify transducer bias/OK status, clean terminals, and confirm alarm setpoints through the TDI configuration.

- Firmware & records – Keep configuration backups and, where applicable, maintain firmware alignment across cards.

Quality & Certifications

- Typically compliant with CE and UL/cUL for industrial control equipment

- CSA and ATEX/IECEx options are common within the 3500 Series (check nameplate for the exact module variant)

- Manufactured under ISO 9001 quality systems

- Warranty: 365 days

One thing I appreciate is how this module keeps day-to-day work practical: clear terminal layout, predictable behavior in the rack, and diagnostics you can trust during turnarounds. If you’re standardizing on the 3500 framework, 125744-01 fits right into that philosophy of stable monitoring with minimal fuss.

Reviews

There are no reviews yet.