Description

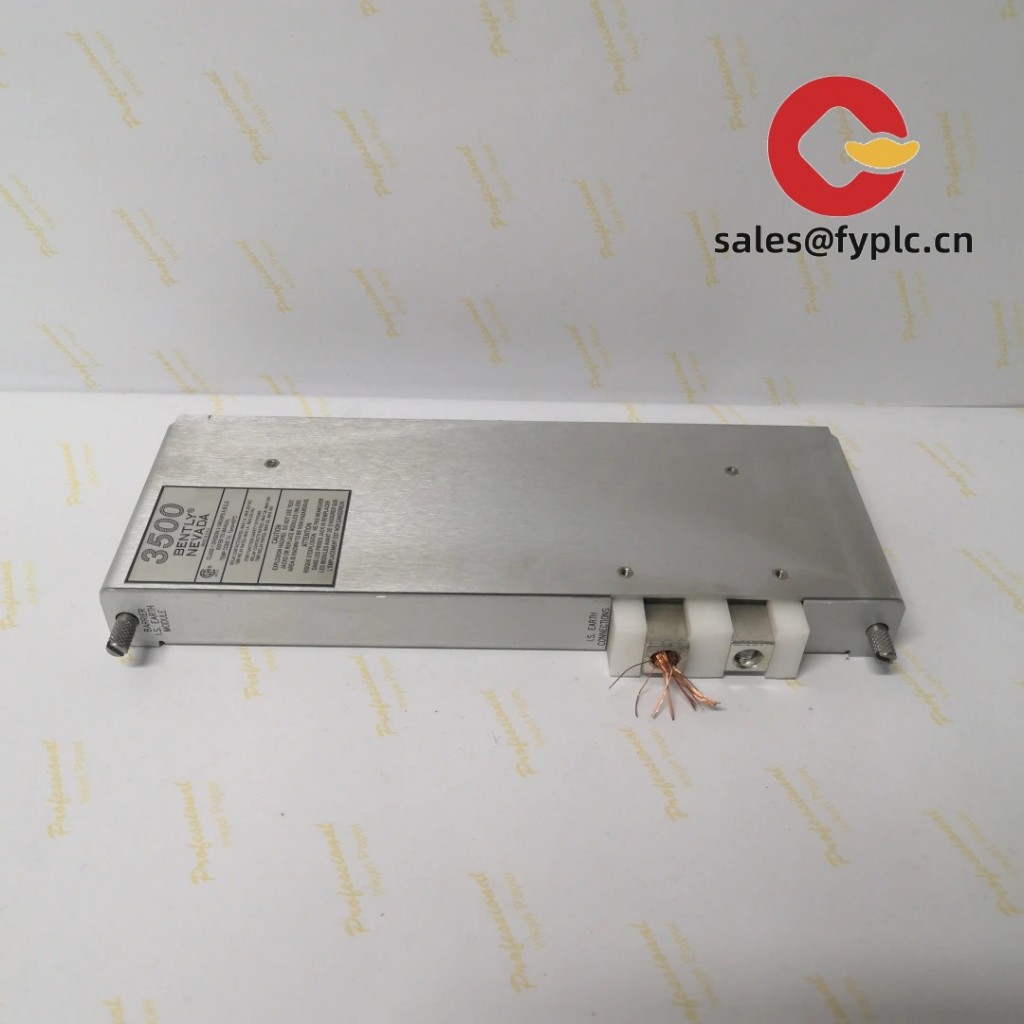

Bently Nevada 136711-01 Temperature Monitoring I/O Module for 3500 Series – Rear I/O for 3500/60 Temperature Monitor

The Bently Nevada 136711-01 is the rear I/O module used with the 3500/60 Temperature Monitor. From my experience, it’s the piece that quietly does the heavy lifting—terminating RTD and thermocouple wiring cleanly, providing cold-junction handling for TCs, and ensuring the temperature channels reach the monitor reliably through the 3500 backplane. If you’re maintaining a 3500 rack, this is a straightforward, drop-in I/O replacement that typically keeps your outage time to a minimum.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Each module is function-tested prior to shipment and packed for shock and ESD protection

Key Features

- Purpose-built for 3500/60 Temperature Monitor – Ensures correct pinout and backplane connectivity with the 3500 rack.

- Multi-sensor support – Typically accepts RTDs (Pt100, 2/3/4‑wire) and common thermocouple types (J, K, T, E, N, R, S, B) via the monitor configuration.

- Clean field wiring – Plug-in terminal blocks help speed up installation and maintenance during turnarounds.

- Stable temperature measurements – Designed to work with the 3500/60’s cold-junction and linearization capabilities for consistent readings.

- Backplane powered – No external power wiring; the module draws from the 3500 rack.

- Drop-in replacement – Fits the standard 3500 rear I/O slot; no cabinet rework in most cases.

Technical Specifications

| Brand / Model | Bently Nevada 136711-01 (3500 Series I/O for 3500/60 Temperature Monitor) |

| HS Code | 903289 (Automatic regulating or controlling instruments and apparatus) – commonly used for 3500 modules |

| Power Requirements | Powered via 3500 rack backplane; no external supply required |

| Signal Input / Output Types | Field terminations for RTDs (Pt100 2/3/4‑wire) and Thermocouples (J, K, T, E, N, R, S, B); channels processed by 3500/60 monitor |

| Communication Interfaces | None on the I/O module; system interfaces via 3500 backplane and 3500/22M TDI (e.g., Ethernet/Modbus at system level) |

| Operating Temperature | 0 to +65 °C (32 to 149 °F) typical; 5–95% RH non‑condensing |

| Dimensions & Weight | Standard 3500 rear I/O form factor; approximate weight ≈ 0.3 kg |

| Installation Method | Rear-mounted on 3500 rack; plug-in terminal blocks; retained with screws for vibration environments |

| Compatibility | Designed for the 3500/60 Temperature Monitor within 3500 racks; works with 3500/15 Power Supply, 3500/22M TDI, 3500/32M Relay modules in the same system |

Application Fields

You’ll typically see the 136711-01 in continuous machinery protection systems where temperature is a primary indicator: compressor and turbine bearing metal temps, gearbox oil and casing temps, motor and generator stator winding RTDs, and high-value pump sets. It’s common across oil & gas, petrochemical plants, power generation (GT/ST), steel mills, pulp & paper, and large water treatment facilities—anywhere a 3500 rack is watching critical rotating assets.

Advantages & Value

- Reliability in harsh environments – Built for industrial cabinets with vibration and temperature swings.

- Exact fit, faster turnaround – Minimizes wiring changes and helps cut downtime during maintenance windows.

- System-level compatibility – Plays nicely with the rest of the 3500 ecosystem, which, in many cases, simplifies spares and configuration management.

- Practical cost control – A targeted replacement of the I/O module rather than full monitor swaps can materially reduce spend.

- Pre-shipment testing – From my experience, verified functionality before dispatch saves hours in the field.

A maintenance supervisor in a Gulf Coast refinery told us they swapped a 136711-01 during a night shift and had their bearing RTDs reading correctly within an hour—no re-termination hassle, no rework on the door layout.

Installation & Maintenance

- Panel/Cabinet – Install in a 3500 rack mounted within a ventilated cabinet; keep ambient within 0–65 °C and away from high EMI sources.

- Wiring practices – Use shielded twisted pairs for RTDs; for thermocouples, use proper TC-grade extension wire and avoid routing alongside power cables.

- Grounding – Maintain single-point grounding for shields; avoid ground loops that can skew low-level temperature signals.

- ESD & handling – Observe ESD precautions when inserting/removing the I/O module and terminal blocks.

- Routine checks – Verify terminal tightness during outages; spot-check calibration against a known reference if temperature drift is suspected.

- Firmware/config – Temperature linearization and alarm settings live in the 3500/60/TDI configuration; review after any channel or sensor changes.

Quality & Certifications

- CE compliant; UL/cUL for industrial control equipment (IEC/UL 61010-1) – typical for 3500-series modules

- RoHS compliant (2011/65/EU and amendments), depending on production lot

- Manufactured under ISO 9001 quality systems

- Seller warranty: 365 days

Related/Supporting Components

- Bently Nevada 3500/60 Temperature Monitor – mates with 136711-01 rear I/O

- Bently Nevada 3500/22M TDI – system interface for configuration and data (Ethernet/Modbus)

- Bently Nevada 3500/15 Power Supply – redundant supply options in the rack

- Bently Nevada 3500/32M Relay Module – alarm and trip relays driven by monitor conditions

Note: Specific sensor type support and channel configurations are determined by the paired 3500/60 monitor and its configuration. If you’re replacing an I/O module in a mixed-RTD/TC cabinet, share a photo of the existing terminal labeling and we can help double-check wiring continuity and channel mapping before you power back up.

Reviews

There are no reviews yet.