Description

BENTLY Nevada 140734-05 Dynamic Pressure Monitoring Module – Continuous combustion and pulsation insight for critical rotating assets

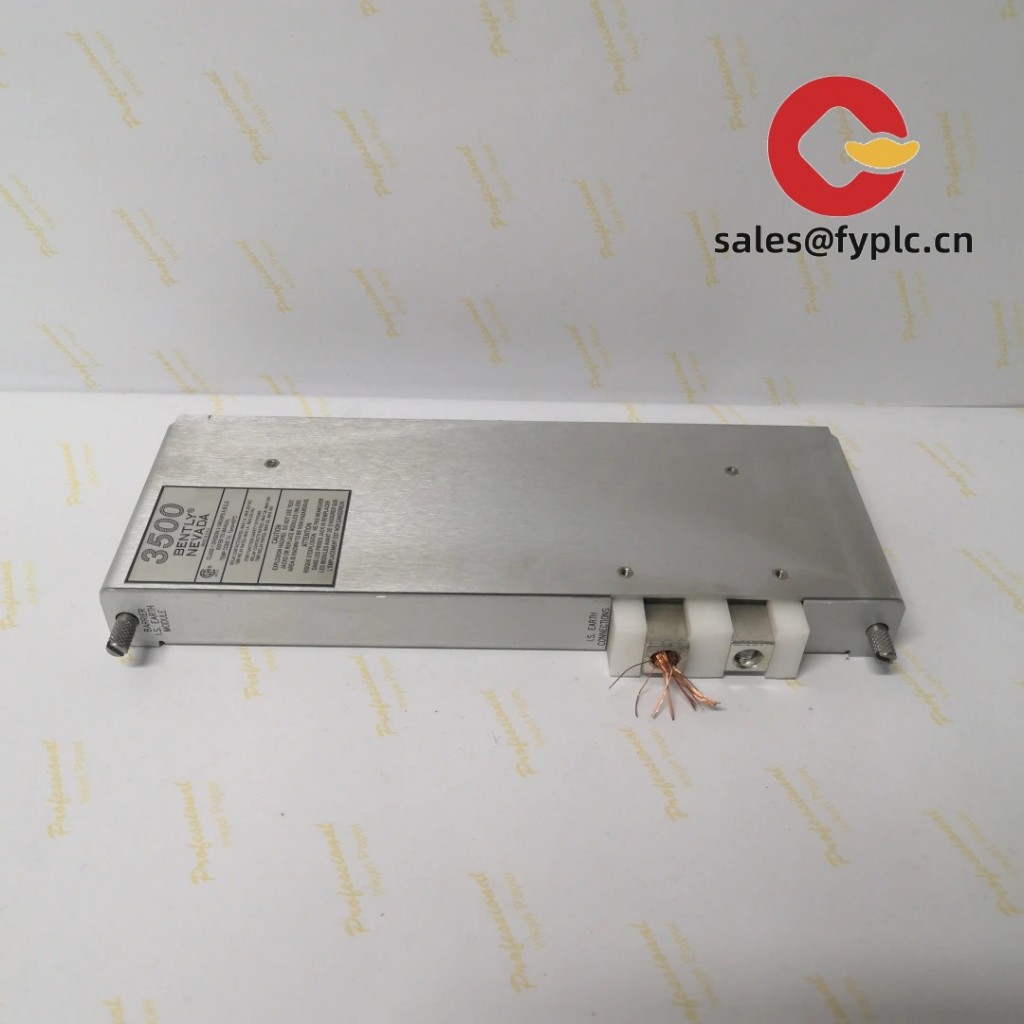

The BENTLY Nevada 140734-05 is a dynamic pressure monitoring module designed for high-speed, high-fidelity pressure signal analysis. From my experience, this type of module is typically deployed in BENTLY Nevada 3500 racks to track combustion dynamics on gas turbines, detect pulsation in compressors, and spot resonance or surge conditions before they become production losses. You might notice that it behaves much like the trusted BENTLY vibration channels, but tuned for dynamic pressure transducers, giving you a clean window into combustion stability and acoustic phenomena.

Order Placement Process & Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Dynamic pressure channels: Optimized for piezoelectric pressure sensors to capture combustion and pulsation signatures with high bandwidth.

- Real-time alarms (Alert/Danger): Configurable setpoints help you catch instability, surge, or flameout precursors early.

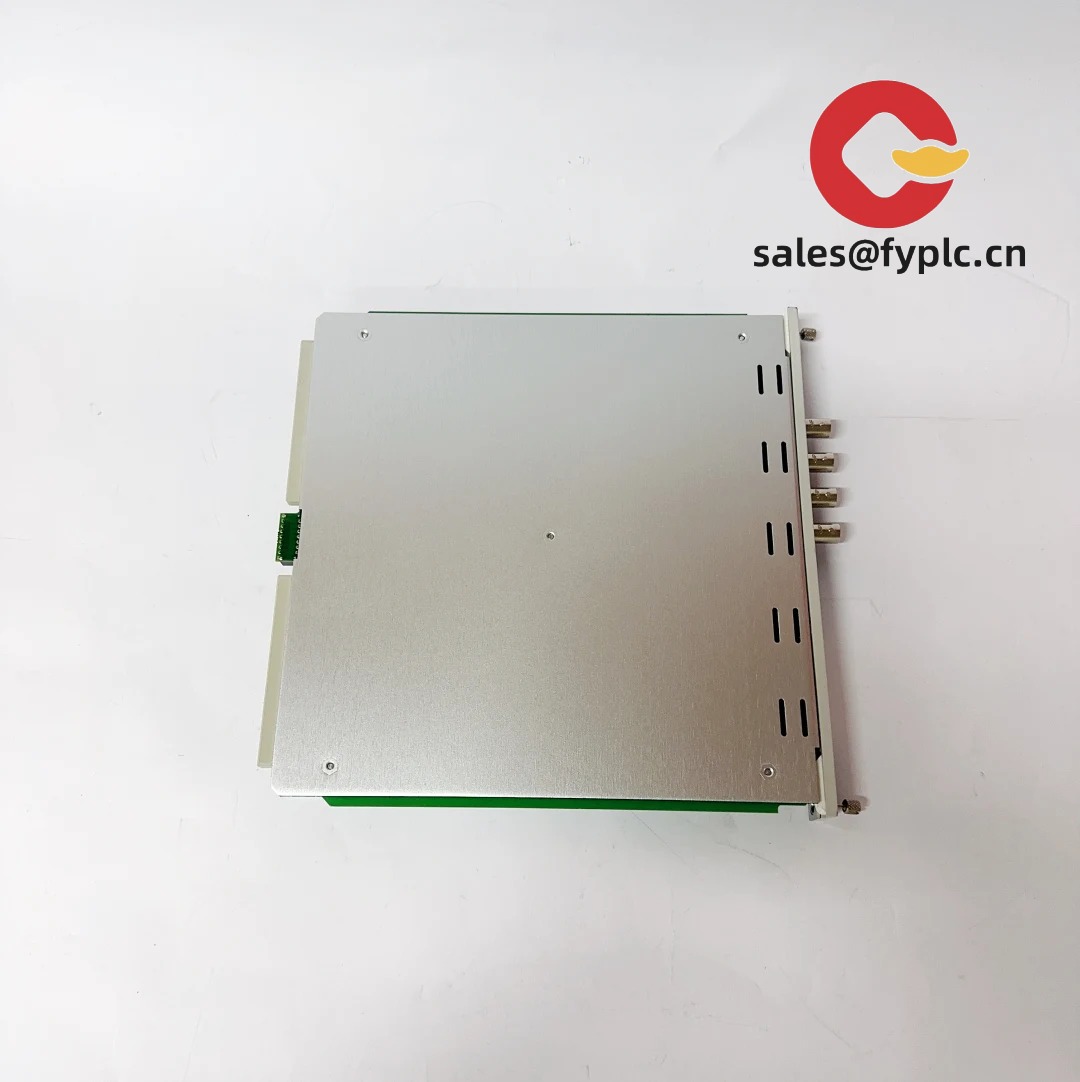

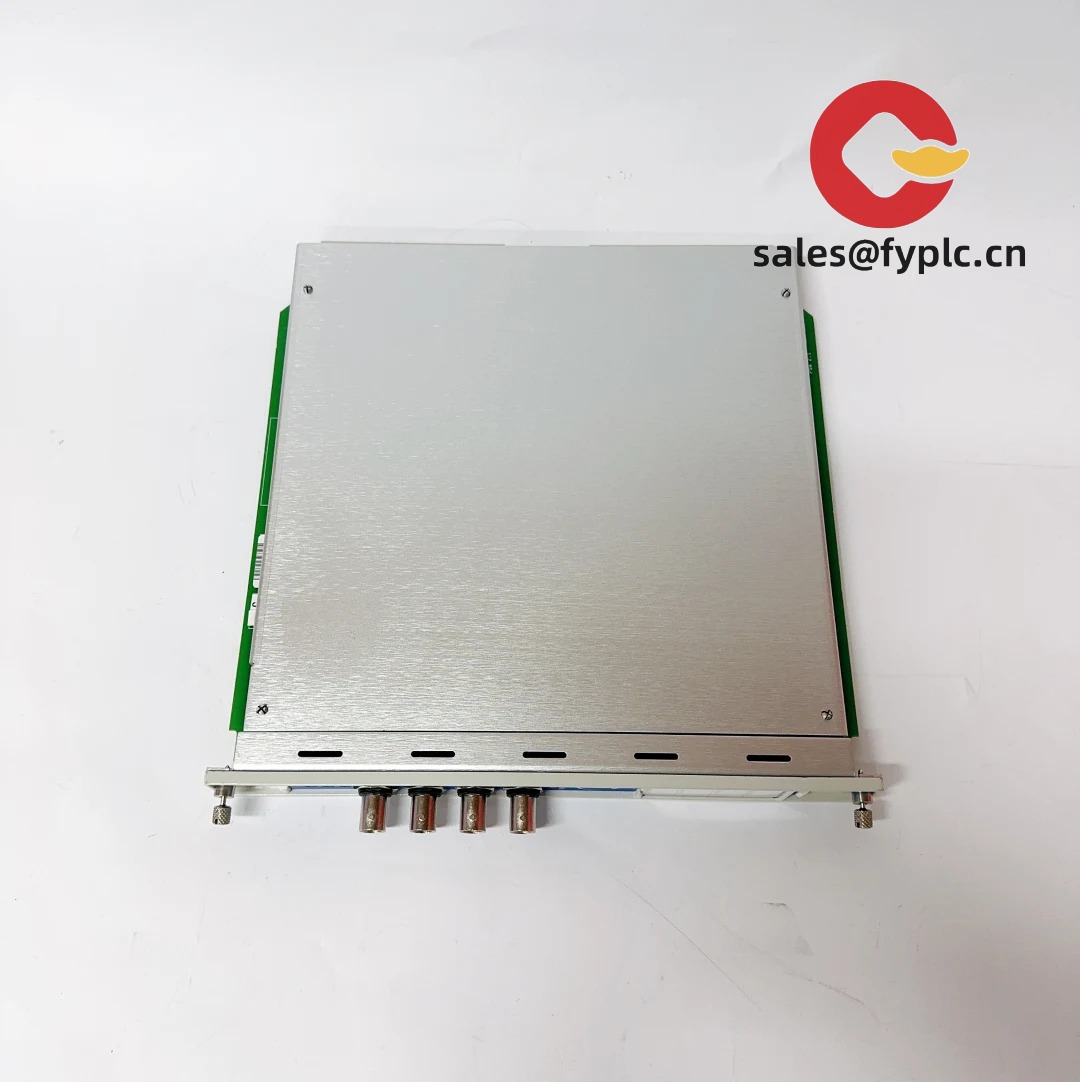

- Buffered dynamic outputs: Front-panel BNC typically provides raw signal access for analyzers or portable recorders.

- Keyphasor correlation (when available): Phase-referenced analysis for order tracking and synchronous investigations.

- Rack integration: Works within the BENTLY Nevada rack ecosystem, leveraging backplane power, alarm relays, and system communications.

- Noise-resistant measurements: Designed for harsh, high-EMI environments found around turbines and compressors.

Technical Specifications

| Brand / Model | BENTLY Nevada 140734-05 |

| HS Code | 9032.89 (Automatic regulating or controlling instruments and apparatus – Other) |

| Power Requirements | Powered via rack backplane; no separate external supply required |

| Dimensions & Weight | Single-slot plug-in module for BENTLY Nevada rack; typical 3U height, ~280 mm depth, ~0.4 kg |

| Operating Temperature | 0 to +65°C (typical for BENTLY rack modules) |

| Signal Input Types | Piezoelectric dynamic pressure transducers (IEPE/ICP or charge-type via conditioner); optional Keyphasor reference |

| Signal Outputs | Buffered dynamic output (front BNC); alarm status to rack relays; values available to system comms |

| Communication Interfaces | Via rack communications module (e.g., Ethernet through system monitor, where present) |

| Installation Method | Front-insert, rear I/O terminal base; single-slot rack mounting with field wiring at the rear |

Application Fields

- Gas turbine combustion dynamics monitoring (DLN/lean-premix stability tracking).

- Reciprocating compressor pulsation detection and anti-surge diagnostics.

- Boiler and furnace acoustic monitoring to spot instability or flame anomalies.

- Hydroacoustic/pipe resonance surveys in high-pressure process lines.

- R&D and test stands needing phase-referenced pressure spectra and trends.

A maintenance engineer at a combined-cycle plant shared that adding dynamic pressure channels reduced nuisance turbine trips by letting them see and correct combustion rumble during load transitions.

Advantages & Value

- Reliability: Industrial-grade design that typically holds calibration and signal integrity even near hot sections.

- Compatibility: Seamless use with BENTLY racks, Keyphasor references, and existing historian/controls via rack comms.

- Cost-conscious: Early detection of combustion instabilities and pulsations often prevents expensive unplanned outages.

- Data confidence: Buffered outputs for portable analyzers; easy correlation with vibration and process tags.

- Lifecycle support: Spares, configurable alarms, and firmware upgradability help extend system life in many cases.

Installation & Maintenance

- Cabinet & environment: Install in a clean, ventilated 19-inch cabinet; maintain ambient 0–65°C, humidity below condensation.

- Wiring: Use shielded, low-noise cables for dynamic pressure sensors; ground shields at the rack end; keep sensor cables away from power lines.

- Sensors: Pair with suitable IEPE or charge-type dynamic pressure transducers; verify mount torque and orientation per OEM sensor guidance.

- Safety: De-energize the rack slot before insertion or removal; follow site LOTO procedures.

- Routine checks: Quarterly inspection of connector tightness, channel bias/health, and sensor drift; clean dust from front panel openings.

- Calibration & firmware: Annual calibration against a reference source is recommended; keep firmware aligned with the rack system monitor for stability.

Quality & Certifications

- CE conformity; typically UL/cUL recognized for system use

- RoHS compliant design

- Manufactured under ISO 9001 quality systems

- Standard warranty: 365 days

From my experience, pairing the 140734-05 with a stable Keyphasor and well-sited dynamic pressure sensors gives the clearest picture of combustion behavior, especially during startup and low-load operation. If you’re consolidating spares, this module seems to be a practical pick for fleets running modern DLN turbines or high-speed reciprocating compressors.

Reviews

There are no reviews yet.