Description

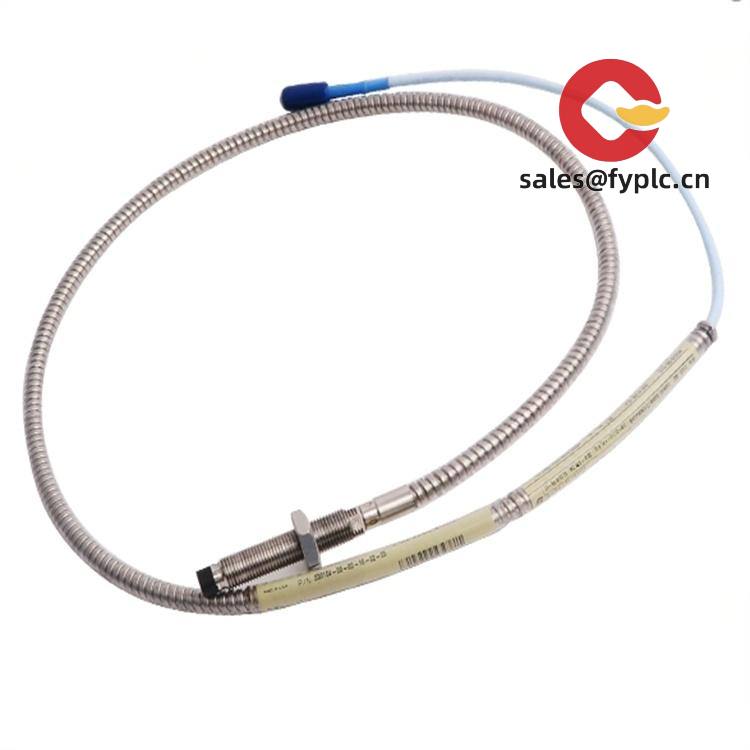

BENTLY 330180-91-00 Proximitor Preamplifier – Eddy-current proximity sensor conditioning for reliable shaft vibration and position

The BENTLY 330180-91-00 is a Proximitor-style preamplifier used with Bently Nevada eddy-current proximity probes to deliver stable gap voltage and clean dynamic vibration signals to your monitoring system. From my experience, this is the part that makes the probe “come alive,” converting minute changes in the magnetic field at the probe tip into a precise DC gap and an AC vibration signal your monitors can trust. It’s typically paired with 3300 XL 5 mm or 8 mm probes and the matching extension cable to form a calibrated system length (commonly 5 m or 9 m).

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery: fedex, UPS, DHL

Key Features

- Designed for eddy-current proximity probes: Works as the conditioning preamplifier for Bently Nevada proximity probe systems, providing DC gap and AC vibration output.

- Stable scale factor: Delivers the standard -200 mV/mil (≈7.87 mV/μm) sensitivity many users expect for 5 mm/8 mm systems, so data lines up with plant standards.

- Industrial temperature range: Built for harsh environments; typically performs from -35°C to +85°C without drift issues that cause bad trending.

- Noise-resistant construction: Potted electronics and proper shielding help reduce EMI/RFI pickup—handy near VFDs and large motors.

- System length compatibility: Supports calibrated probe–extension cable–preamplifier combinations (often 5 m or 9 m), maintaining accuracy over the full range.

- Analog outputs for most monitors: Provides a negative DC bias (gap) plus dynamic AC signal to vibration monitors or protection racks.

Technical Specifications

| Brand / Model | BENTLY 330180-91-00 (Proximitor preamplifier for eddy-current proximity probes) |

| HS Code | 903180 (Other measuring or checking instruments) |

| Power Requirements | Supplied from monitor channel; nominal -24 VDC, low current draw (typical proximitor level) |

| Operating Temperature | -35°C to +85°C (typical for 3300/3300 XL-fielded installations) |

| Signal Input / Output | Input: Eddy-current probe coil; Output: DC gap voltage and AC vibration signal, nominal -200 mV/mil (≈7.87 mV/μm) |

| Communication Interfaces | Analog only (no digital comms) |

| Installation Method | Panel/bulkhead mounting near the machine; shielded wiring to monitor; matched probe and extension cable lengths |

| Compatible Accessories | BENTLY 330932 (5 mm proximity probe), BENTLY 330130 (extension cable), matching Bently monitors |

Application Fields

You’ll typically see the 330180-91-00 in critical rotating equipment where precision shaft dynamics matter:

- Steam and gas turbines – axial position (thrust), radial vibration, and slow-roll checks

- Compressors and expanders – continuous protection and condition monitoring

- Large motors, pumps, and fans – bearing health, misalignment, and rub detection

- Gearboxes – monitoring gear mesh dynamics and shaft runout

Advantages & Value

- Reliability that keeps trending clean: In many cases, these preamps hold calibration well, so your bias voltage and amplitude stay consistent across outages.

- Seamless compatibility: Designed to work with Bently proximity probes and extension cables—less guesswork, fewer mixing-supplier issues.

- Lower lifecycle costs: Stable hardware reduces nuisance alarms and the time techs spend re-zeroing gaps or chasing intermittent noise.

- Supportable in the field: Technicians appreciate the typical -200 mV/mil scale; it matches procedures, tooling, and historical data.

One thing I appreciate is how predictable the bias voltage behaves when the system length is correct. A maintenance engineer at a refinery told us swapping to the 330180-91-00 eliminated a recurring “gap drift” issue during hot restarts—seems to be the tighter temperature behavior and better shielding in their panel.

Installation & Maintenance

- Mounting & environment: Install the preamplifier near the machine in a clean, dry panel. Provide ventilation and keep it away from high-EMI sources (VFD outputs, soft-starters) when possible.

- Wiring & grounding: Use shielded cables; ground shields at the monitor end per Bently practices. Keep probe/extension cable lengths to the calibrated system (commonly 5 m or 9 m).

- Initial setup: Set the probe gap with a micrometer or target fixture. Verify nominal bias (often around -10 to -18 VDC depending on target and gap) and dynamic response.

- Routine checks: Periodically inspect connectors, verify insulation integrity, and clean terminals. Confirm bias voltage stability after thermal cycles.

- Calibration & firmware: No firmware. If you change probe or cable lengths, recalibrate the system length to maintain scale factor and linearity.

Quality & Certifications

- CE compliant; RoHS-conformant materials used in most recent builds

- UL/CSA recognized components in many deployments

- Manufactured under ISO 9001 quality systems (typical for Bently Nevada production)

- Our supply warranty: 365 days from shipment

If you’re standardizing spares, pairing 330180-91-00 with 330932 probes and 330130 extension cables typically keeps calibration consistent across units and reduces time on installations.

Reviews

There are no reviews yet.