Description

Bently Nevada 3500/92-01-01-00 Communication Gateway Module – Ethernet bridge for 3500 rack data to DCS/SCADA

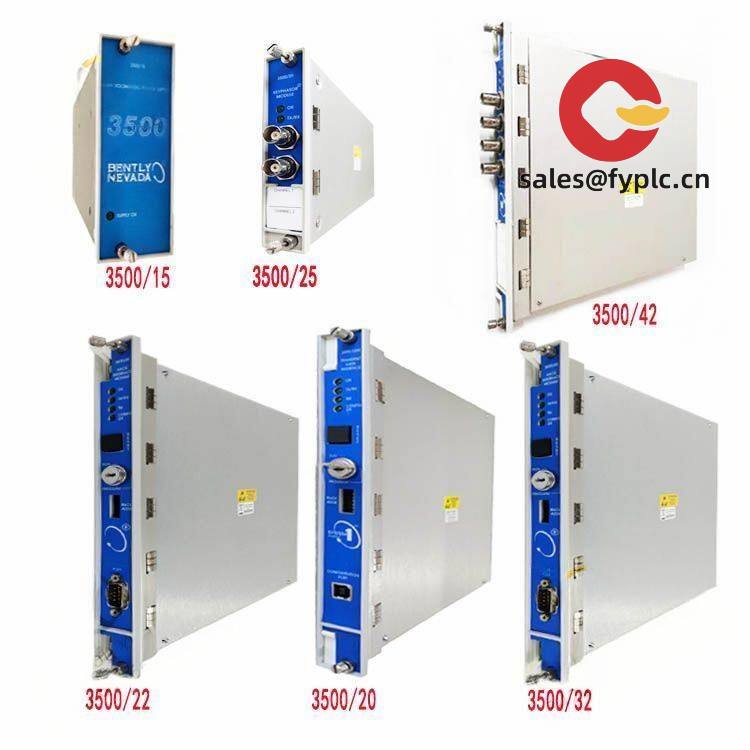

The Bently Nevada 3500/92-01-01-00 is the communications gateway module for the 3500 system. From my experience, plants use it when they want clean, reliable access to the 3500 rack’s measurement values, statuses, and alarms over standard Ethernet—typically to feed DCS, PLC, or SCADA historians. You might notice that it’s favored because it sits in the rack backplane, not as an add‑on box, which keeps wiring simple and data consistent.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Ethernet communications to plant systems – Provides an Ethernet link to read 3500 rack data for DCS/SCADA and historians, typically via standard industrial protocols.

- Rack‑backplane integration – Pulls measurements, statuses, and alarm/event information directly from the 3500 backplane, so no extra signal wiring is needed.

- Simple deployment – Installs as a 3500 single‑slot module; powered from the rack, with no separate power supply in most cases.

- Status LEDs for quick diagnostics – You can typically verify module health and link activity at a glance during commissioning.

- Designed for critical machinery environments – Matches the 3500 platform’s reliability profile used on turbines, compressors, and balance‑of‑plant assets.

Technical Specifications

| Brand / Model | Bently Nevada 3500/92-01-01-00 |

| HS Code | 9032.90.00 (parts/accessories for automatic regulating/controlling instruments) |

| Power Requirements | Powered from the 3500 rack backplane; no external power supply |

| Dimensions & Weight | 3500 standard single‑slot module form factor (fits any 3500 rack); lightweight module |

| Operating Temperature | Typically 0 to +65 °C (32 to 149 °F) |

| Signal I/O Types | Digital data only; no direct transducer inputs |

| Communication Interfaces | 10/100Base‑TX Ethernet (RJ‑45); protocol support commonly includes Modbus TCP |

| Installation Method | Hot‑swappable 3500 rack module (follow ESD and lockout procedures); configuration through standard 3500 tools |

Application Fields

Plants typically use the 3500/92 to publish vibration, speed, axial position, temperature, and system alarm status from the 3500 rack to higher‑level systems. It’s widely deployed in:

- Oil & gas (compressor trains, pumps, turbines) feeding DCS alarm lists and historian tags

- Power generation (steam and gas turbines) for plant‑wide monitoring dashboards

- Petrochemical & refining units integrating condition data to APC/SCADA

- Steel, paper, mining, and marine where centralized SCADA needs real‑time rack values

One thing I appreciate is how maintenance teams can verify trip conditions and alarm sequences without walking down to the rack; the gateway passes those statuses upstream so they can trend and correlate events quickly.

Advantages & Value

- Reliability: Uses the same robust backplane and design philosophy as the rest of the 3500 series; fewer boxes and fewer failure points.

- Compatibility: Designed for the 3500 platform; data mapping is straightforward for standard points and alarms.

- Cost & footprint: No external power or separate protocol converter, which typically cuts panel space and wiring time.

- Supportability: Common in brownfield integrations, with documentation and tools that most technicians already know.

Feedback we hear often: “Once we mapped the critical tags over Ethernet, our DCS alarm response got faster and our vibration analysts stopped exporting USB logs.” It seems to be a small change that unlocks better workflows.

Installation & Maintenance

- Panel/rack: Install as a single‑slot module in a 3500 rack. Keep adequate ventilation in the cabinet; follow OEM clearances.

- Wiring: Use industrial Ethernet cabling (Cat5e/Cat6). Segregate from high‑noise motor cables and provide proper grounding.

- Network practice: Assign fixed IPs and document tag maps. Many sites keep the 3500 network on a protected VLAN or DMZ for cybersecurity.

- Safety & ESD: Observe lockout/tagout. Use ESD protection when inserting/removing modules. Hot‑swap only per procedure.

- Routine checks: Verify link/OK LEDs, confirm tag updates in the DCS/SCADA, back up configuration, and review firmware/tooling versions periodically.

Supporting components you might pair with this module typically include the 3500 rack and power supply, 3500/22M TDI for configuration and data aggregation, and the appropriate 3500 monitoring cards (e.g., vibration, speed). That combination keeps the data path clean end‑to‑end.

Quality & Certifications

- Typically CE marked and UL/cUL for industrial control equipment

- RoHS conformity for hazardous substances (module level)

- Manufacturer quality system aligned with ISO 9001

- Warranty: 365 days

Reviews

There are no reviews yet.