Description

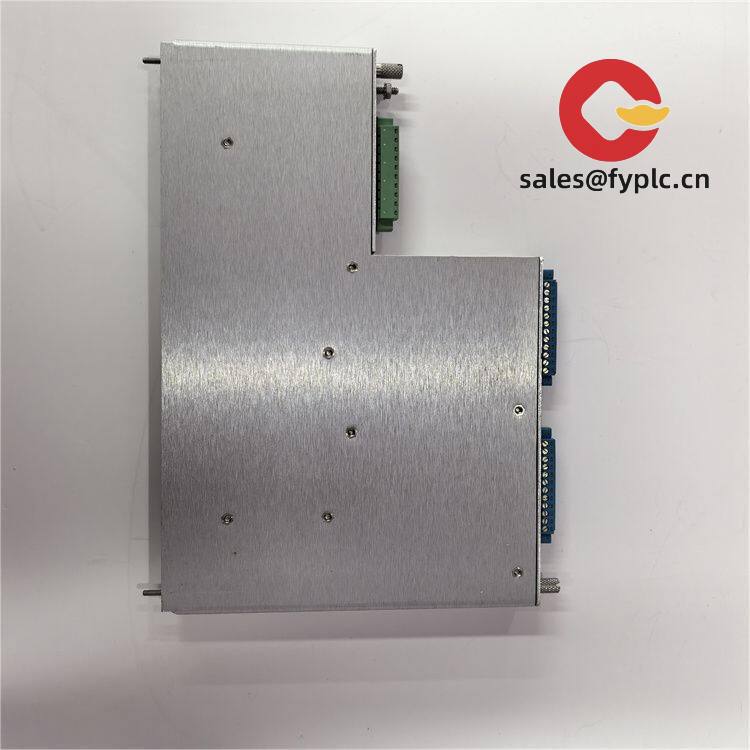

Bently Nevada 135489-02 (3500/92) Communication Gateway – Modbus TCP/RTU bridge for 3500 machinery protection racks

From my experience, when someone asks for “3500/42 Communication Gateway Modbus,” what they typically mean is the Bently Nevada 3500/92 Communication Gateway, and the part code 135489-02 aligns with that gateway family. The 3500/42 is a Proximitor/Seismic Monitor, whereas the 3500/92 is the module that exposes rack data over Modbus. If your goal is to feed vibration, status, and alarm data from a 3500 rack to a DCS/PLC via Modbus, this is the right module.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Process: Confirm model/options → Proforma invoice → Prepayment → Functional testing and packing → Balance payment → Courier dispatch with tracking

Key Features

- Modbus TCP and RTU support: Presents 3500 rack values, statuses, and alarms to DCS/PLC via Ethernet or serial lines.

- Read‑only gateway design: In many cases, data is exposed read-only for protection integrity; control remains within the 3500 system.

- Rack‑wide data access: Pulls measurements and alarm states from multiple monitoring modules through the rack backplane.

- Flexible serial wiring: Typically supports RS‑232 and RS‑485/422 for long runs and multi‑drop topologies.

- Industrial Ethernet: 10/100Base‑T, making it straightforward to drop into most plant networks.

- Standard 3500 rack integration: Powered and synchronized via the rack; no extra power supply in most cases.

- Simple configuration: Modbus register mapping provided; configured using Bently Nevada 3500 configuration software.

Technical Specifications

| Brand / Model | Bently Nevada 3500/92 Communication Gateway (P/N 135489-02) |

| Function | Modbus gateway for 3500 rack data (measurements, statuses, alarms) |

| HS Code | 8517.62 (Data communication apparatus) |

| Power Requirements | Powered via 3500 rack backplane; no external power supply typically required |

| Communication Interfaces | 1× 10/100Base‑T Ethernet; 1× RS‑232; 1× RS‑422/485 (Modbus TCP/RTU) |

| Signal I/O Types | Data gateway only; no transducer inputs; exposes mapped Modbus registers and discrete status bits |

| Operating Temperature | Typically 0 to +60 °C (installation in a protected control cabinet recommended) |

| Dimensions & Weight | Standard 3500 rack module form factor; weight commonly under 0.5 kg |

| Installation Method | Rack‑mounted in a Bently Nevada 3500 Series rack; backplane connection |

| Typical Compatibility | Works with 3500 racks, commonly with 3500/22M TDI for system communications |

Application Fields

You might notice that the gateway is most valuable where the protection system must share live condition data with plant control. Typical uses include:

- Oil & Gas – Send vibration trends and alarm states to DCS for compressors, pumps, and turbines.

- Power Generation – Map bearing and casing measurements to PLCs for steam/gas turbine condition displays.

- Petrochemical & Refining – Integrate protection data into APC and shutdown logic via Modbus RTU/RS‑485.

- Pulp & Paper, Mining – Centralize machine health KPIs for operators without adding new wiring to each monitor.

A maintenance engineer at a refinery told us they brought a new compressor train online faster because the 3500/92’s Modbus TCP mapping dropped straight into their DCS templates—no custom driver needed.

Advantages & Value

- Reliable integration: Read‑only architecture helps preserve protection integrity while sharing the data operations need.

- Reduced engineering time: Standard Modbus maps typically cut PLC/DCS programming and testing efforts.

- Broad compatibility: Works with common DCS/PLC brands (Modbus is still the lingua franca in many plants).

- Lower wiring complexity: One Ethernet or RS‑485 link can expose many channels, which in many cases replaces dozens of analog signals.

- Service & spares flexibility: Standard 3500 module format, easy stocking and replacement procedures.

Installation & Maintenance

- Cabinet & environment: Install in a clean, ventilated control cabinet; keep within the temperature range and away from high‑EMI sources.

- Wiring tips: Use shielded twisted pair for RS‑485; follow proper grounding/segregation; for Ethernet, dedicated VLANs or firewalled subnets are recommended.

- Configuration: Define Modbus maps and node parameters with Bently Nevada configuration tools; document register addresses for the DCS/PLC team.

- Safety: De‑energize the rack before module insertion/removal unless your site procedure specifically allows online replacement.

- Routine care: Periodically verify communications, back up configuration files, check firmware revisions, and inspect connectors for looseness or corrosion.

Quality & Certifications

- CE compliant; UL/CSA certifications are typically available for the 3500 platform.

- RoHS compliant in most configurations of the 3500 series.

- Manufacturer’s standard quality controls for 3500 modules apply; our warranty covers 365 days from delivery.

Reviews

There are no reviews yet.