Description

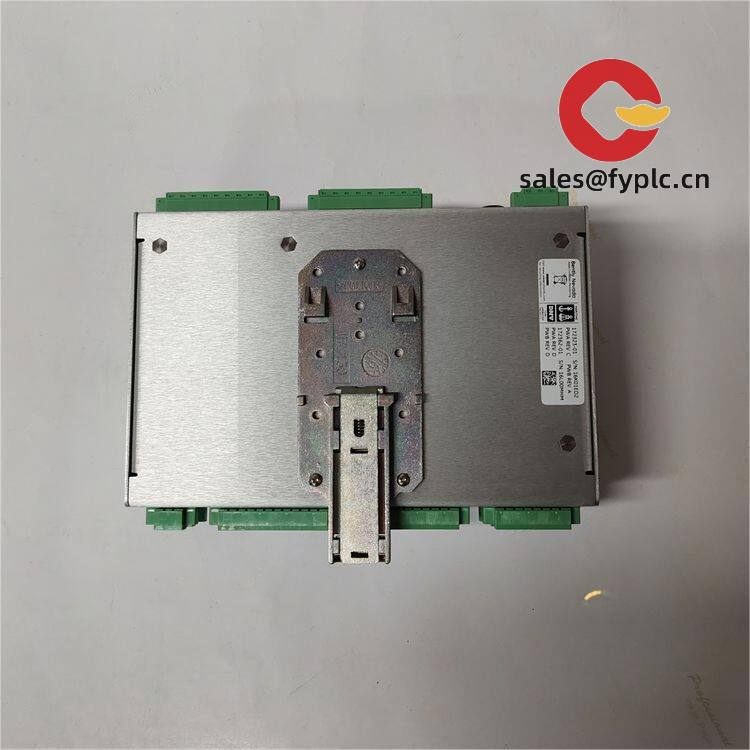

Bently Nevada 1900/65A-00-00-01-00-00 General Purpose Equipment Monitor – Compact Machinery Protection for Pumps, Fans, and Motors

The Bently Nevada 1900/65A is a standalone general-purpose equipment monitor designed for continuous vibration and speed monitoring on non-critical or essential rotating assets. From my experience, it fits best on pumps, blowers, small compressors, gearboxes, and electric motors where you want reliable protection and simple 4–20 mA/relay interfaces to a DCS or PLC—without the complexity of a full rack system. One thing I appreciate is how flexible it is with sensors: proximitor systems, accelerometers, and velocity pickups are typically supported, so you can standardize across different machines.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Two-channel vibration + speed (typical 1900/65A build) – Covers radial vibration on bearings and a Keyphasor/speed input for alarm logic and trending.

- Universal sensor compatibility – Works with proximity probes (shaft vibration/position), industrial accelerometers, and velocity sensors on fans, motors, and pumps.

- Industrial outputs for easy integration – 4–20 mA proportional outputs and configurable alarm relays to tie in with PLC/DCS safety or interlocks.

- Modbus connectivity – RS‑485 Modbus RTU is commonly used for remote values and status in SCADA systems.

- Buffered signal access – Buffered BNCs for portable analyzers, making on-site diagnostics fast without rewiring.

- DIN-rail friendly footprint – Fits neatly in compact panels, which is great on skid packages and MCC rooms where space is tight.

- Field-proven protection logic – Standard alert/danger alarms and voting schemes aligned with common industry practice for condition monitoring.

Note on this configuration: 1900/65A-00-00-01-00-00 appears to be a standard general‑purpose option set. The “-01” position typically indicates a build that supports a speed/Keyphasor channel along with vibration channels. If you need us to verify the exact channel map and relay count against your P&ID, we can confirm before shipping.

Technical Specifications

| Brand / Model | Bently Nevada 1900/65A-00-00-01-00-00 |

| HS Code | 9031.80.00 (Measuring/monitoring instruments; for guidance in most regions) |

| Power Requirements | 24 VDC nominal (typical industrial DC supply) |

| Signal Inputs | Up to 2 vibration channels (accelerometer/velocity/proximity) + 1 Keyphasor/speed input |

| Signal Outputs | 4–20 mA per channel; alarm relays (Form C); buffered BNCs for diagnostics |

| Communication | RS‑485 (Modbus RTU) for values, status, and alarms |

| Installation Method | DIN‑rail or back‑panel mounting inside a protective control cabinet |

| Operating Temperature | -35 °C to +70 °C (typical rating for the 1900 series) |

Application Fields

The 1900/65A is commonly deployed on:

- Water & wastewater – pump skids, aeration blowers, and lift stations

- Chemicals & refining – auxiliary pumps, cooling tower fans, and small gearboxes

- Power generation – condensate and boiler feed pumps, ID/FD fans

- Food & beverage – process pumps and packaging line drives

- Mining & cement – conveyor drives, ventilation fans, slurry pumps

Advantages & Value

- Right-sized cost for essential assets – In many cases, it’s far more economical than a rack system while still providing protection-level alarms.

- Simplified integration – 4–20 mA and Modbus RTU make it straightforward to drop into existing control schemes.

- Sensor flexibility – Reuse existing Bently Nevada prox probes or industrial accelerometers to minimize retrofit costs.

- Serviceability – Buffered outputs and front-access wiring typically reduce troubleshooting time.

- Lead time and lifecycle – Seems to be easier to source than larger systems, and firmware/config tools are stable across the series.

Installation & Maintenance

- Cabinet & mounting – Install on 35 mm DIN rail or a rigid back panel inside an IP54 (or better) enclosure; allow ventilation clearance around the unit.

- Power & grounding – Use a clean 24 VDC supply; bond shields at the monitor end; maintain a solid protective earth to reduce noise.

- Wiring practices – Route transducer and Keyphasor cables away from VFD power; use twisted/shielded pairs; keep sensor cables and relay wiring segregated.

- Commissioning – Perform sensor checks (gap on proximities; bias on accelerometers), verify 4–20 mA scaling, and test alert/danger setpoints with simulated inputs.

- Routine maintenance – Quarterly visual inspection and connector re-torque; annual alarm logic review; keep firmware/config backups aligned with site standards.

Quality & Certifications

- Typically supplied with CE and UL/cUL compliance for industrial use

- RoHS-conformant build in most shipments

- Manufactured under ISO 9001 quality systems (vendor-level)

- Our warranty coverage: 365 days

Compatible Sensors & Accessories (Common Choices)

- Bently Nevada 3300 XL proximity probe systems for shaft vibration/position

- Bently Nevada 330400/330425 industrial accelerometers for bearing vibration

- Bently Nevada 330500 Velomitor velocity sensors for fans and gearboxes

- Bently Nevada Keyphasor probes for speed and phase reference

If your site standard requires a specific 1900/65A option set (e.g., relay count, transducer type, or agency approvals), share the exact suffix code from your BOM. We’ll cross-check the -00-00-01-00-00 configuration for compatibility with your sensors and PLC/DCS interface before placing the order.

Reviews

There are no reviews yet.