Description

NI cFP-DO-403 Digital Output Module – Reliable DC Switching for Compact FieldPoint Systems

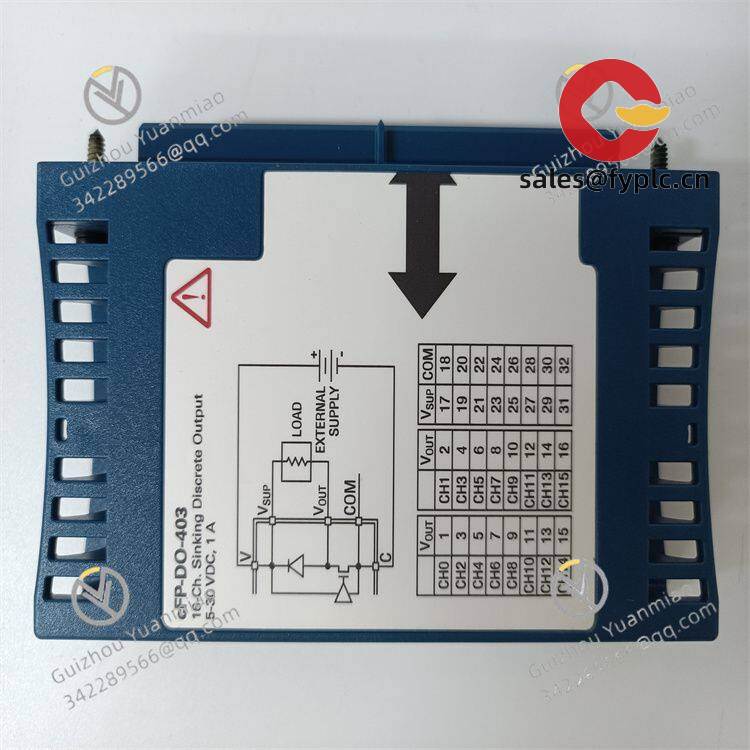

The NI cFP‑DO‑403 is a Compact FieldPoint digital output module designed for straightforward DC load control—think valves, contactors, indicator lamps, and small solenoids on distributed machines. One thing I appreciate is how it slots straight into a cFP terminal base and is recognized by the controller with minimal fuss. In many cases, teams use it to offload simple on/off tasks from the main PLC, keeping critical logic lean while adding flexible I/O at the edge.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Compact FieldPoint integration – Plugs into a cFP terminal base and communicates over the cFP backplane via a cFP controller or network interface.

- Transistor-based digital outputs – Suited for DC load switching; stable behavior for on/off control in industrial cabinets.

- Isolation between field and backplane – Reduces noise coupling and helps protect the controller side in most cabinet environments.

- Per‑channel status LEDs – Quick visual verification; you can see channel states at a glance during commissioning.

- Hot‑swappable module design – Typically allows quick replacement with minimal system downtime.

- Watchdog/fail‑safe options (via cFP controller) – Sets safe output states on communication loss; useful for remote sites.

- LabVIEW/FieldPoint software support – Works with NI‑FieldPoint APIs and LabVIEW Real‑Time on cFP controllers for fast setup.

Technical Specifications

| Brand / Model | NI (National Instruments) cFP‑DO‑403 (also seen as CFP‑DO‑403) |

| HS Code | 8537.10 (Boards/panels for electric control or distribution) |

| Power Requirements | Powered via the Compact FieldPoint backplane; field loads use an external DC supply appropriate to the output rating. |

| Dimensions & Weight | Standard Compact FieldPoint plug‑in module form factor; fits cFP terminal bases. |

| Operating Temperature | Typically −40 to +70 °C (cFP family range; confirm for installed environment) |

| Signal Output Type | Digital outputs, transistor switching (DC); field‑powered loads |

| Communication Interfaces | Via cFP backplane to a cFP network interface (e.g., cFP‑18xx) or cFP controller (cFP‑20xx); configured with NI‑FieldPoint / LabVIEW RT |

| Installation Method | Plug‑in to cFP terminal base (e.g., cFP‑CB‑1 or cFP‑CB‑3); DIN‑rail mounting via base/carrier |

Application Fields

From my experience, the cFP‑DO‑403 shines in distributed control where you want rugged I/O near the machine:

- OEM machinery: on/off control of pneumatic valves, motor contactors, stack lights

- Water & wastewater: local pump/valve actuation with remote telemetry

- Power/utilities: switching of relays and interlocks in sub‑panels

- Process skids: safe states and watchdog behavior during controller handovers

- Packaging and material handling: actuator triggering and lane diverter control

A maintenance lead at a packaging plant told us their team liked the simple channel LEDs—during a jam they could verify outputs without booting a laptop, which typically saves minutes per event.

Advantages & Value

- Reliability – Rugged cFP construction for cabinet environments; isolation reduces nuisance faults.

- Compatibility – Works with existing cFP controllers and NI‑FieldPoint projects; easy drop‑in for legacy expansions.

- Cost efficiency – Distributed I/O often cuts wiring runs and cabinet real estate; fewer terminations back at the main PLC.

- Supportability – Clear diagnostics and stable driver support in LabVIEW RT shorten troubleshooting time.

Installation & Maintenance

- Cabinet & mounting – Install on a DIN‑rail with the appropriate cFP base; allow airflow and keep within rated ambient temperature.

- Power & wiring – Use a clean DC field supply sized for the total load; segregate signal and power wiring; tighten terminal screws to spec.

- Safety – De‑energize field power before servicing; verify safe states with the controller’s watchdog during maintenance.

- Routine care – Periodically check terminal torque, clean dust with dry air, and validate output actions in I/O tests after firmware or driver updates.

Supporting components you may consider: cFP‑CB‑1 or cFP‑CB‑3 terminal bases (screw/spring), a cFP‑18xx network interface or cFP‑20xx controller, and a regulated 24 VDC supply sized for your loads.

Quality & Certifications

- CE marked; UL/cUL recognized (module family)

- RoHS compliance typically available depending on production lot; we can verify at order time

- Manufacturer quality system: ISO 9001

- Standard manufacturer warranty practices apply; our sales warranty is 365 days as stated above

If you share your channel count and load details (voltage/current, inductive or resistive), we can confirm the exact output rating, terminal base options, and ship a matched kit to simplify installation.

Reviews

There are no reviews yet.