Description

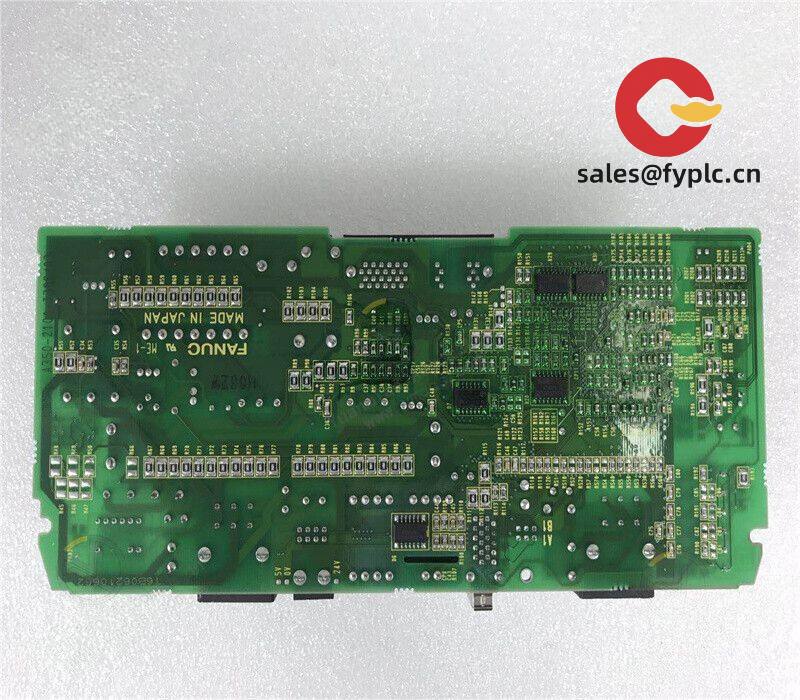

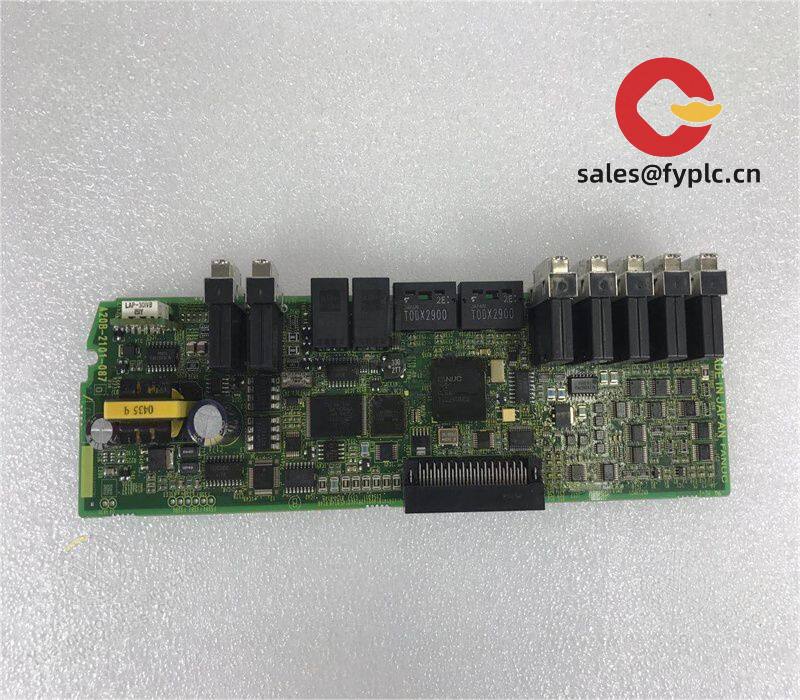

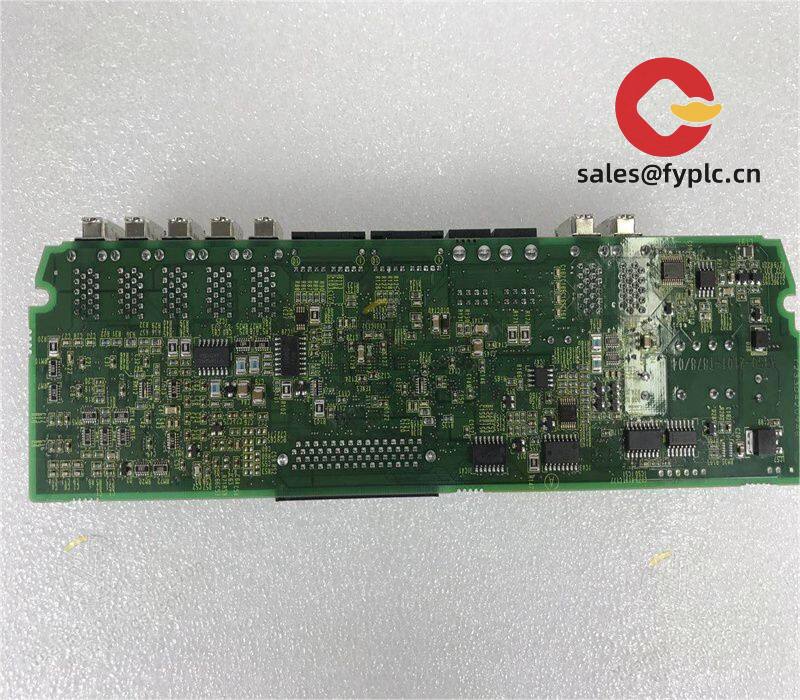

FANUC A20B-2001-0065/06A System Master Board – Core CPU/Controller Board for FANUC CNC Systems

The FANUC A20B-2001-0065/06A is a system master board designed to serve as the central CPU/control board inside a FANUC CNC rack. It typically restores boot, communications, and peripheral handling on machines where the control won’t initialize or shows CPU-related alarms. From my experience, it’s a straight swap for the matching part/suffix and gets aging FANUC 16/18/21-era machines back into production without the headache of a full control retrofit.

Company’s Order Placement Process and Guarantees

- Inquiry & Verification: Share your controller series and current part/suffix. We double-check compatibility (the “/06A” matters) before you commit.

- Quotation & Lead Time: You receive a clear offer with condition (new/refurb/tested), price, and delivery. In-stock items ship in 1 week; not in stock is usually within 2–4 weeks, no more than one month at the latest.

- Payment Terms: 50% advance payment to reserve and test; full payment prior to delivery.

- Packing & Dispatch: Anti-static + foam-packed. Express options: FedEx, UPS, DHL.

- Warranty: 365-day warranty. If it doesn’t perform as specified, we support you with replacement or repair under our policy.

Key Features

- Drop-in replacement for matching FANUC controls – Typically used in FANUC 16/18/21 series systems; match the exact part and suffix “A20B-2001-0065/06A” for the safest swap.

- Backplane-powered design – Draws regulated DC from the CNC rack; no special field wiring to the board itself.

- Stable CPU and memory architecture – Helps recover controls that hang at boot or throw CPU/Watchdog-type alarms.

- I/O and peripheral handling – Interfaces to the system bus for I/O units, MDI/CRT, and maintenance ports; some builds support RS-232C directly, others via option boards.

- Industrial temperature rating – In many cases specified for 0–55°C control cabinet environments.

- Tested before delivery – Each unit is typically bench-tested on a compatible rig to verify boot and bus communication.

Technical Specifications

| Brand / Model | FANUC A20B-2001-0065/06A (System Master Board) |

| HS Code | 8538.90 (Parts for switchgear/panels of heading 8537) |

| Power Requirements | Supplied via FANUC backplane; logic +5 VDC typical (overall consumption varies by configuration) |

| Dimensions & Weight | A20B board form factor; typical board-level assembly, approx 0.6–0.8 kg (indicative) |

| Operating Temperature | 0–55°C; 5–95% RH non‑condensing (cabinet environment) |

| Signal I/O Types | System backplane bus to I/O units; maintenance/serial port as equipped; peripheral headers per build |

| Communication Interfaces | RS‑232C (common), FANUC I/O Link; optional Ethernet via expansion on some systems |

| Installation Method | Plug-in board on CNC rack/backplane with card guides and screws; ESD-safe handling required |

Application Fields

You’ll typically find the A20B-2001-0065/06A in FANUC-controlled machine tools: vertical and horizontal machining centers, turning centers, grinders, and some EDMs from the late 1990s to early 2000s era. It’s commonly selected when the original control won’t boot, shows watchdog/CPU alarms, or loses communication with I/O soon after power-up.

A maintenance lead from a Tier-2 automotive shop told us: “Swapped this board into a 16‑M control, restored parameters from our backup, and we were cutting parts again in under two hours.” That echoes what we usually see—when the part/suffix matches, recovery can be surprisingly quick.

Advantages & Value

- Fast downtime recovery – A direct replacement is almost always the most time‑efficient fix vs. retrofitting a new control.

- Compatibility-first approach – We verify the “/06A” revision and your machine’s control series to avoid parameter headaches later.

- Cost containment – Extends the service life of existing assets without redesigning electrical cabinets or wiring looms.

- Tested units with support – Guidance on backing up/restoring CNC & PMC data, plus after-sales help if the control shows new alarms.

Installation & Maintenance

- Environment – Install in a clean, dry CNC cabinet with adequate ventilation; typical ambient 0–55°C. Keep fans and filters in good order.

- ESD safety – Power down, discharge, and handle via the board edges. Use an ESD wrist strap; avoid flexing the PCB.

- Fitment – Seat the board evenly in the backplane, then secure with screws/brackets in the card guides. Don’t force connectors.

- Data & parameters – Before removal, back up CNC, PMC, and option data (SRAM/flash). After installation, restore and verify system alarms. You might notice that some machines require a battery check for SRAM-retained data.

- Routine care – Periodically clean dust, inspect connectors, and keep cabinet temperatures stable. Firmware changes should only be done if required by the OEM or to solve a documented issue.

Quality & Certifications

- Built to FANUC industrial standards; units supplied typically comply with CE/UL marking at the system level.

- RoHS compliance may vary by production year; refurbished units are functionally tested and inspected.

- Warranty: 365 days under our standard terms.

Related & Supporting Components

To complete a control-side repair, you may also need:

- FANUC power supply units (e.g., A16B-1212-xxxx series) used in the same CNC rack.

- FANUC I/O modules and I/O Link units that interface via the system backplane.

- MDI/CRT or LCD/MDI operator panels compatible with your control generation.

- Optional communication or memory boards if your machine relies on RS-232C, Ethernet, or expanded program storage.

Quick tip: Matching the exact suffix “/06A” is critical. If you’re unsure, send a photo of your nameplate and the CNC series (e.g., 16‑M, 18‑T). We’ll validate before you place the order.

Reviews

There are no reviews yet.