Description

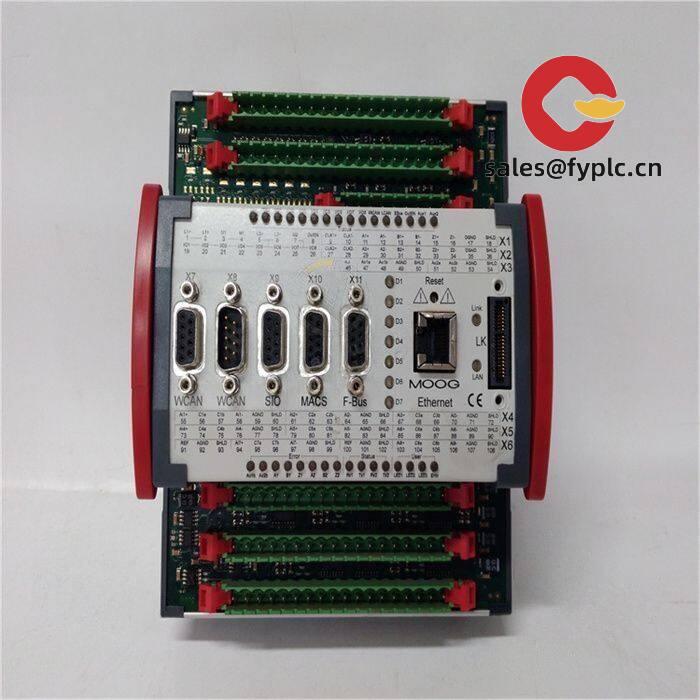

MOOG D138-002-012 Intelligent Servo Controller – Precise, Reliable Motion Control for Demanding Machines

The MOOG D138-002-012 is designed for high-precision closed-loop control in industrial environments where repeatability and uptime really matter. From my experience, D138-series controllers typically sit at the heart of hydraulic or electric servo axes, pairing neatly with MOOG servo valves, actuators, or third‑party drives via standard analog and fieldbus interfaces. You might notice that it’s equally comfortable running a tight position loop on a test stand as it is coordinating pressure or velocity on a production line. It seems to be a sensible pick when you want MOOG-grade dynamics with straightforward panel installation.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express Options: FedEx, UPS, DHL

- Each unit is inspected and securely packed; we share photos and basic functional checks before shipment upon request.

Key Features

- Closed-loop servo control – Typically supports position, velocity, and pressure/force loops for hydraulic or electric axes.

- Flexible signal I/O – ±10 V analog I/O and 24 VDC digital I/O make it easy to interface with drives, servo valves, sensors, and PLCs.

- Industrial communications – Ethernet (for configuration/diagnostics) with fieldbus options such as CANopen or RS‑485/Modbus RTU in many cases.

- High response for demanding dynamics – Tuned for fast, stable control typical of MOOG servo systems on test rigs or press applications.

- DIN‑rail panel mounting – Compact footprint intended for EN 60715 rails, which simplifies cabinet layouts and service access.

- Robust diagnostics – Status LEDs, basic fault codes, and software tools that speed up commissioning and troubleshooting.

- Accessory ecosystem – Works with common MOOG accessories like LVDT/encoder feedback modules, I/O expansion blocks, and screened wiring kits.

Technical Specifications

Values below reflect typical configurations used with the MOOG D138 family and may vary by final build or firmware option. If your process is sensitive to a specific parameter, tell me and I’ll verify against the exact batch before shipping.

| Brand / Model | MOOG D138-002-012 Intelligent Servo Controller |

| HS Code | 8537.10 (Boards, panels, consoles for electric control, ≤1000 V) |

| Power Requirements | 24 VDC nominal (18–32 VDC); typical consumption ≈ 10–15 W depending on I/O load |

| Dimensions & Weight | Approx. 120 × 50 × 115 mm; ~0.6 kg (panel/DIN‑rail module) |

| Operating Temperature | 0 to +55 °C (panel mounted), non‑condensing; storage −20 to +70 °C |

| Signal I/O Types | 24 VDC DI/DO; Analog ±10 V and 4–20 mA (typical); feedback options for incremental/SSI encoders or LVDT when paired with appropriate modules |

| Communication Interfaces | Ethernet (TCP/IP for configuration), CANopen, RS‑485/Modbus RTU; EtherCAT as an option in many deployments |

| Installation Method | DIN‑rail (EN 60715) inside an industrial control cabinet; front pluggable connectors for serviceability |

| Protection & Compliance | IP20 (panel), CE marking and RoHS compliant in most cases |

Application Fields

- Hydraulic test stands and HIL rigs requiring tight position/force control

- Metal forming, press and roll applications where response and stability are critical

- Injection molding and die‑casting machines (pressure/velocity loops)

- Aerospace & automotive component testing, durability benches

- Precision motion on special‑purpose machinery and advanced robotics

Advantages & Value for Procurement

- Reliability that lowers downtime – MOOG control hardware is known for long service life; fewer nuisance trips on production lines.

- Compatibility with existing assets – Plays well with MOOG servo valves/actuators and third‑party PLCs via analog and common fieldbuses.

- Configurable rather than custom – In many cases you avoid expensive redesigns; parameters and firmware options cover most use cases.

- Lifecycle support – We assist with selection, commissioning tips, and stocking spares so maintenance teams feel comfortable.

- Transparent logistics – Clear lead times, pre‑shipment checks, and major express couriers reduce uncertainty.

Installation & Maintenance

- Cabinet & mounting – Install on EN 60715 DIN‑rail inside a ventilated cabinet (IP54 or better for harsh areas). Leave clearance for airflow and service.

- Power & grounding – Use a clean 24 VDC supply with proper grounding. Shielded cables for analog/feedback lines; tie shields at a single point to minimize noise.

- Wiring practices – Separate power and signal runs; route encoder/LVDT leads away from contactors and VFDs. Label connectors for quick swap‑outs.

- Commissioning – Set loop gains conservatively, then step up. Save parameter sets and back them up to a laptop or secure drive.

- Routine maintenance – Quarterly inspection of terminals, check cabinet temperature, clean dust filters. Firmware updates applied during scheduled stops.

- Safety – Implement emergency stop and interlocks via your safety PLC; verify I/O isolation and observe lock‑out/tag‑out procedures.

Quality & Certifications

- CE conformity and RoHS compliance are typical for D138‑series controllers

- UL/cUL recognition available on many builds; MOOG manufacturing under ISO 9001 QMS

- Manufacturer’s warranty: 365 days; we support verification and traceability upon request

Suggested Supporting Components

- MOOG servo valves and manifold kits for hydraulic axes

- Encoder/LVDT feedback modules and shielded cable assemblies

- 24 VDC industrial power supplies with redundancy modules

- DIN‑rail I/O expansion blocks for additional digital/analog channels

Reviews

There are no reviews yet.