Description

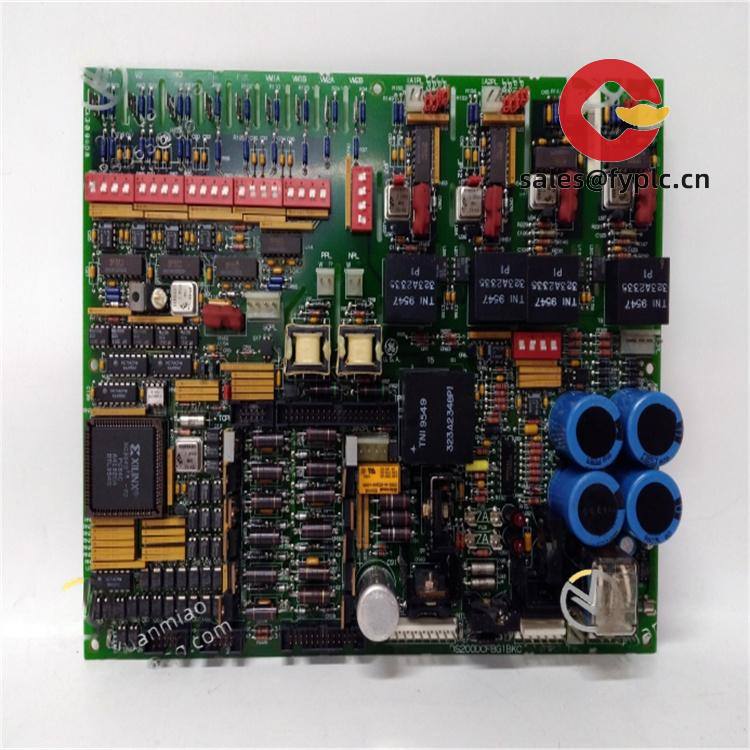

GE DS200DMCBG1AED Isolation Terminal Board – Clean, Isolated Field I/O for DS200/Mark V-Based Systems

The GE DS200DMCBG1AED is an isolation terminal board designed for DS200-series and many Mark V/drive control installations. From my experience, it’s typically used to bring field signals into the control safely—providing galvanic isolation, noise immunity, and a tidy termination point for maintenance teams. If you’re stabilizing noisy field wiring, or you need a clean interface between your controller and instruments, this board tends to be the straightforward, reliable choice.

Order Placement Process and Guarantees

-

- – Warranty: 365 days

-

- – Delivery time: 1 week when in stock; no more than one month at the latest

-

- – Payment terms: 50% advance payment; full payment prior to delivery

- – Express shipping: FedEx, UPS, DHL

Key Features

- Galvanic isolation of field signals – Helps protect the controller from ground loops and electrical noise common in industrial environments.

- Clean termination for wiring – Well-laid-out terminal points make field installation and service quicker; you might notice fewer wiring errors during commissioning.

- Optimized for GE DS200/Mark V drive control – Designed to work within the established GE control ecosystem for simpler drop-in replacement.

- Typical discrete I/O isolation – Often used with 24 VDC dry contacts or relay interfaces where isolation and noise filtering are needed.

- Rugged industrial design – Built for cabinet installation with stable mechanical support; in many cases includes protective conformal coatings depending on revision and sourcing.

- Service-friendly layout – From my experience, clearly labeled test points and terminals reduce troubleshooting time.

Technical Specifications

| Brand / Model | GE DS200DMCBG1AED |

| HS Code | 8538.90 (Parts suitable for electrical control/switchgear) |

| Power Requirements | Supplied from control backplane; typically 5 VDC logic power (low wattage) |

| Operating Temperature | 0 to 60 °C (typical control cabinet conditions) |

| Signal Input/Output Types | Isolated discrete inputs/outputs; commonly 24 VDC dry contact or relay-coupled signals |

| Communication Interfaces | Backplane/edge connectors to DS200 controller; no external fieldbus port |

| Dimensions & Weight | DS200 standard board format; approx. 330 × 280 mm; approx. 0.9 kg (typical) |

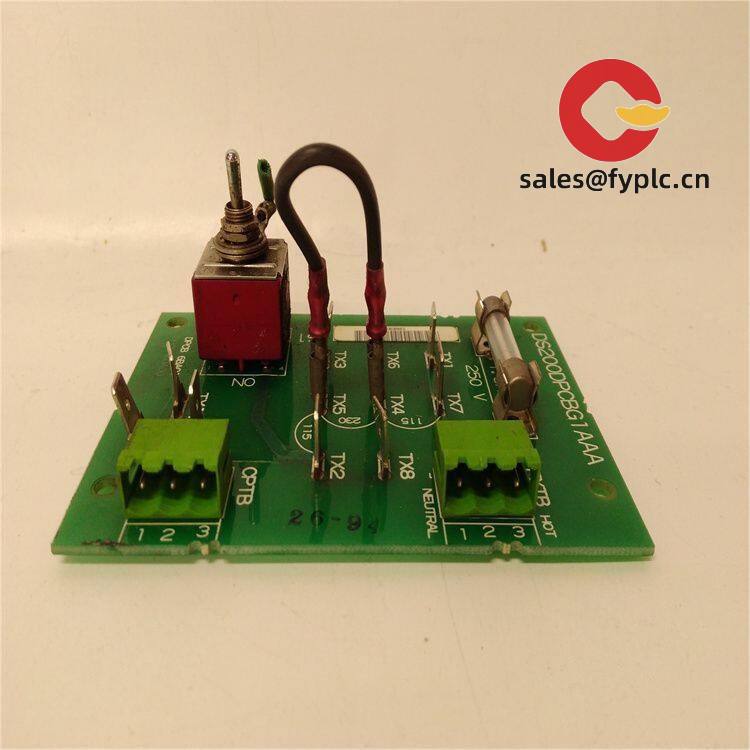

| Installation Method | Cabinet/rack mounting with standoffs; mates via backplane or ribbon harnesses to controller |

Note: Values above reflect typical DS200 isolation boards and may vary slightly by revision. If you need exact measurements or consumption figures for DS200DMCBG1AED, we can confirm against your installed base.

Application Fields

This board is commonly used in GE DS200/Mark V-based control systems across:

- Power generation (turbine auxiliary systems, balance-of-plant I/O isolation)

- Drives and motion (DC/AC drive cabinets where field discretes need isolation)

- Oil & gas and petrochemical (noisy field wiring routes, long cable runs)

- Steel, paper, and mining (high EMI environments benefiting from opto-isolation)

- Water/wastewater (remote panel I/O consolidation into the central controller)

One thing I appreciate is how it calms down erratic inputs when you’ve got mixed grounding in older plants. A maintenance lead recently mentioned they saw fewer nuisance trips after moving their door interlocks and limit switches onto this isolated board.

Advantages & Value

- Reliability under electrical noise – Isolation and filtering reduce false triggering and protect the controller.

- Compatibility with existing DS200 systems – A practical spare or replacement that seems to integrate without engineering changes in most cases.

- Maintenance efficiency – Clear terminations and labeling save time during shutdowns and troubleshooting.

- Cost control – Mitigates unplanned downtime from noisy field inputs and helps extend the life of the main control board.

- Supported sourcing – We can help verify revisions and connector compatibility against your current cabinet layout.

Installation & Maintenance

- Environment – Install in a clean, ventilated control cabinet; keep ambient within typical 0–60 °C and non-condensing humidity.

- Wiring – Use shielded cables for long runs; terminate shields at one end to avoid ground loops. Re-torque terminal screws after thermal cycling.

- Grounding – Maintain a single-point reference; isolation helps, but good cabinet grounding is still essential.

- Handling – Observe ESD precautions; power down and discharge stored energy before replacement.

- Routine care – Quarterly visual inspection, dust removal with dry air, and connector reseat if needed. Firmware updates are typically not applicable to this terminal board type.

- Documentation – Match jumpers or field link settings (if present) to your site standard; photograph before swap to reduce errors.

Quality & Certifications

- Manufactured to GE’s industrial quality standards; typically used in CE/UL-compliant systems

- ISO-based quality control at the system level for most installations

- RoHS applicability depends on revision and region; we can verify per lot

- Warranty: 365 days from delivery

If you can share your current controller part numbers and cabinet photos, we’ll double-check DS200DMCBG1AED revision compatibility and connectors. That usually prevents minor surprises during installation.

Reviews

There are no reviews yet.