Description

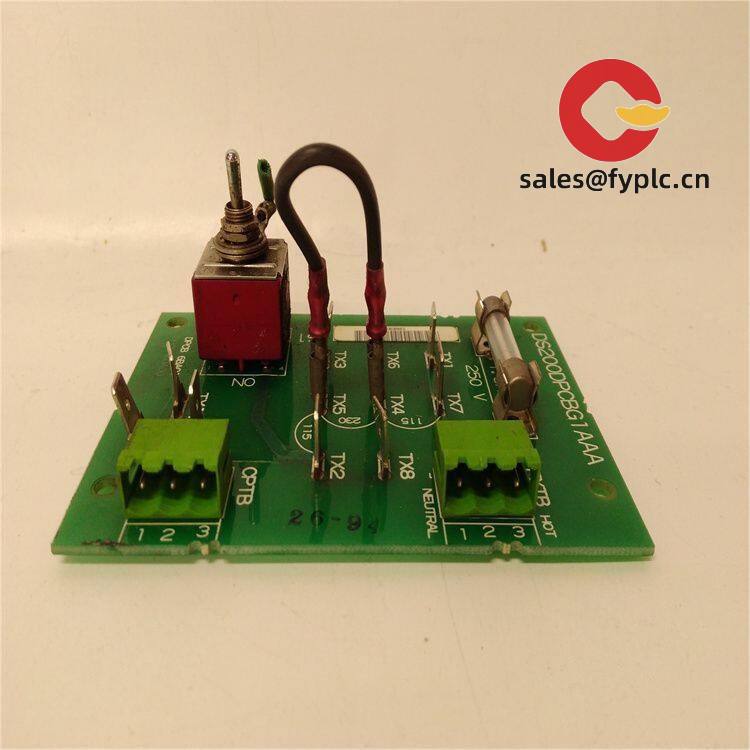

GE DS200DPCBG1AAA – DS200 Series Drive/Excitation Control Module for Power and Protection Interface

The GE DS200DPCBG1AAA is a DS200-series board-level module used across GE industrial drive and excitation cabinets (commonly DC2000/AC2000/EX2000 and Mark V environments). From my experience, this board typically serves in the low-voltage power and protection interface layer—distributing conditioned control power, handling interlocks, and routing critical status signals between the main control card and the surrounding power section. You might notice that it’s designed to mount inside a closed cabinet, with multi-pin edge and ribbon connectors for fast swap-outs during maintenance.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- DS200 family compatibility – Built for GE drive/excitation cabinets, easing integration with installed bases.

- Low-voltage power distribution – Typically routes +5 VDC and ±15 VDC control rails from the cabinet supply to logic and analog sections.

- Protection and interlock routing – Interfaces trip chains, permissives, and status feedback to the main control board.

- Service-friendly connectors – Edge and ribbon headers allow quick board replacement during downtime.

- Status indication – In many cases, onboard LEDs help technicians verify power and basic health at a glance.

- Field-proven construction – Robust PCB design suited for cabinet environments in steel mills, power plants, and process lines.

Technical Specifications

| Brand / Model | GE DS200DPCBG1AAA |

| HS Code | 853890 (Parts for boards/panels for electrical control) |

| Power Requirements | Powered via host cabinet rails; typically +5 VDC logic and ±15 VDC analog distribution |

| Operating Temperature | Cabinet-installed; commonly 0–60°C environment in most drive systems |

| Signal I/O Types | Multi-pin edge connectors, ribbon cable headers, test points/status LEDs (varies by revision) |

| Communication Interfaces | Backplane/cabinet interconnect; no external fieldbus on the board itself |

| Installation Method | Panel/cabinet mounting in GE DS200-based drive or excitation systems; ESD-safe handling required |

| Dimensions & Weight | Board-level module; standard DS200 footprint (consult system layout for clearance) |

Application Fields

This model is well-suited for maintaining GE DC2000/AC2000 drives, EX2000 excitation cabinets, and many Mark V-based turbine auxiliaries. Typical sites include steel and rolling mills, paper and film lines, power generation auxiliaries, oil & gas compressor trains, mining conveyors, and larger OEM machinery that standardized on GE DS200 hardware. One thing I appreciate is how it helps extend the life of installed bases where a full drive migration is not yet justified.

Advantages & Value for Procurement

- Drop-in compatibility – Designed for DS200 architecture, reducing engineering time and retrofit complexity.

- Reduced downtime – Fast replacement thanks to keyed connectors; maintenance teams typically swap in under an hour.

- Lifecycle support – Helps stabilize legacy lines without a full system upgrade, which often saves significant capex.

- Quality-assured part – Sourced and tested under documented procedures; appears to be consistent with GE’s build standards.

- Technical guidance – Application support on wiring references and cabinet placement lowers installation risk.

Installation & Maintenance

- Cabinet conditions – Install in a clean, dry, ventilated enclosure (IEC/NEMA cabinet). Keep ambient typically within 0–60°C.

- Wiring & grounding – Use original harnessing; verify ground continuity and shield terminations to minimize noise.

- ESD safety – Use wrist straps and antistatic mats. Handle by edges; avoid touching components and pins.

- Power sequencing – Isolate cabinet power and wait for DC bus discharge before removal/installation.

- Routine checks – Inspect connectors for oxidation, clean dust with dry air, and verify interlock continuity during scheduled shutdowns.

- Calibration/Firmware – The board itself typically requires no calibration; keep host controller firmware and parameters backed up.

Quality & Certifications

- Manufacturing quality – Built under GE’s quality system, typically aligned with ISO 9001 practices.

- CE/UL context – Component-level board used within CE/UL-certified drive systems; conformity assessed at the cabinet/system level.

- RoHS – Legacy industrial spares may vary by production date; many installations accept component-level exceptions.

- Warranty – 365-day coverage as stated above for workmanship and functional fitness in normal industrial use.

Related & Supporting Components (for planning)

In many cabinets this board is paired with control and interface cards such as DS200SDCCG1A (drive control), DS200PCCAG1A (power interface), and various ribbon harnesses specific to DC2000/AC2000/EX2000 layouts. If you’re lining up a maintenance window, it’s practical to review these part numbers together to avoid repeat downtime.

Reviews

There are no reviews yet.