Description

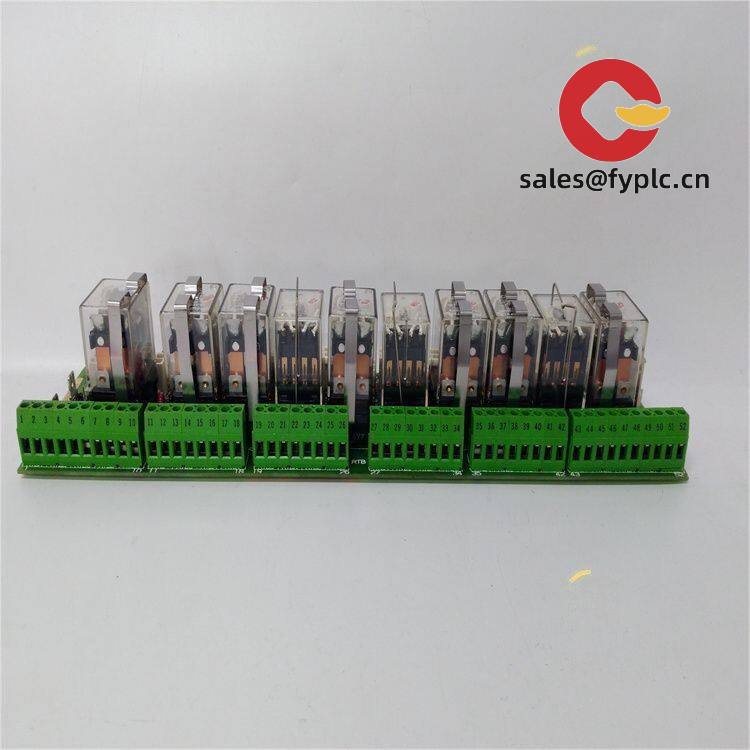

GE DS200RTBAG3AEB Relay Terminal Board – Reliable field relay interface for GE drive, exciter, and turbine control cabinets

The DS200RTBAG3AEB is a GE relay terminal board designed to give you clean, durable handoff between control logic and field devices—contactors, solenoids, permissives, motor starters, and hardwired interlocks. From my experience, teams choose this board when they want stable dry-contact outputs, tidy wiring, and an easy drop-in for DS200-series cabinets (Mark V/EX2000/AC/DC drives). You might notice that it keeps the control side isolated from noisy field circuits, which typically translates into fewer nuisance trips and simpler troubleshooting on site.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: In-stock ships in 1 week; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

- Testing: Functional inspection before dispatch; photos and packing details shared for your records

Key Features

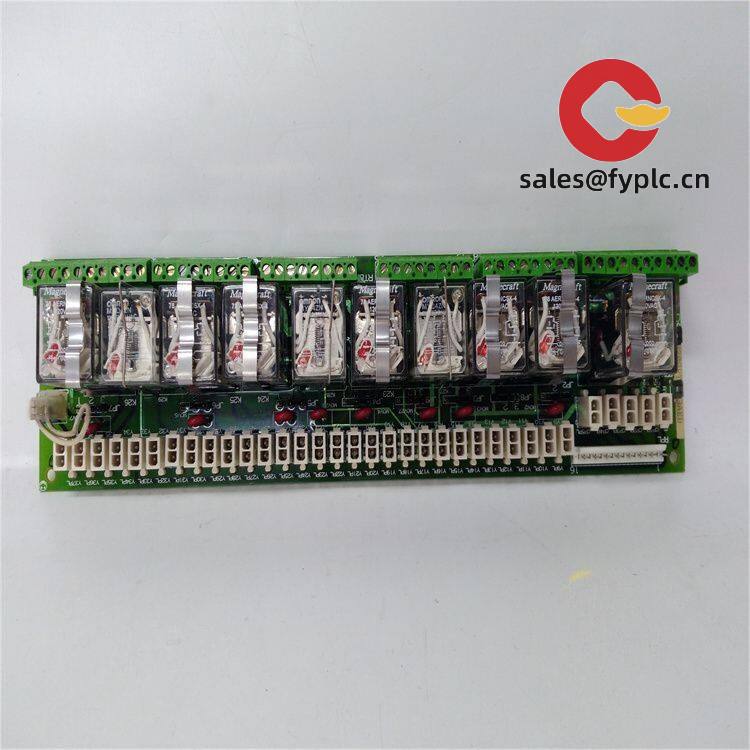

- Field-proven relay outputs – Provides form C (SPDT) dry-contact outputs for robust on/off control of external devices.

- Isolated handoff – Helps keep control logic protected from field-side noise; in many cases this reduces random trips.

- Serviceable, plug-in relays – Technicians can swap relays quickly during planned outages, keeping downtime short.

- Screw terminal blocks – Clear labeling and tight, secure terminations simplify panel wiring and later inspections.

- Direct compatibility with DS200 systems – Designed for GE drive/exciter/turbine cabinets; no custom fabrication in most cases.

- No fieldbus required – Hardwired I/O keeps the design straightforward and easy to diagnose with a meter.

- G3 build variant – The G3 series typically indicates a mature revision with stable field performance records.

Technical Specifications

| Brand / Model | GE DS200RTBAG3AEB (Relay Terminal Board) |

| HS Code | 8537.10 (boards/panels for electric control, ≤1000V) |

| Power Requirements | No onboard PSU; relay coils are driven by the host system. Coil voltage is per cabinet configuration (commonly 115 VAC in GE Mark V/EX2000 builds—verify site BOM). |

| Operating Temperature | 0 to +60°C typical control cabinet environment (non-condensing) |

| Signal I/O Types | Dry-contact relay outputs (SPDT/Form C), field screw terminals; control-side via multi-pin internal connectors |

| Communication Interfaces | None (hardwired I/O; no fieldbus) |

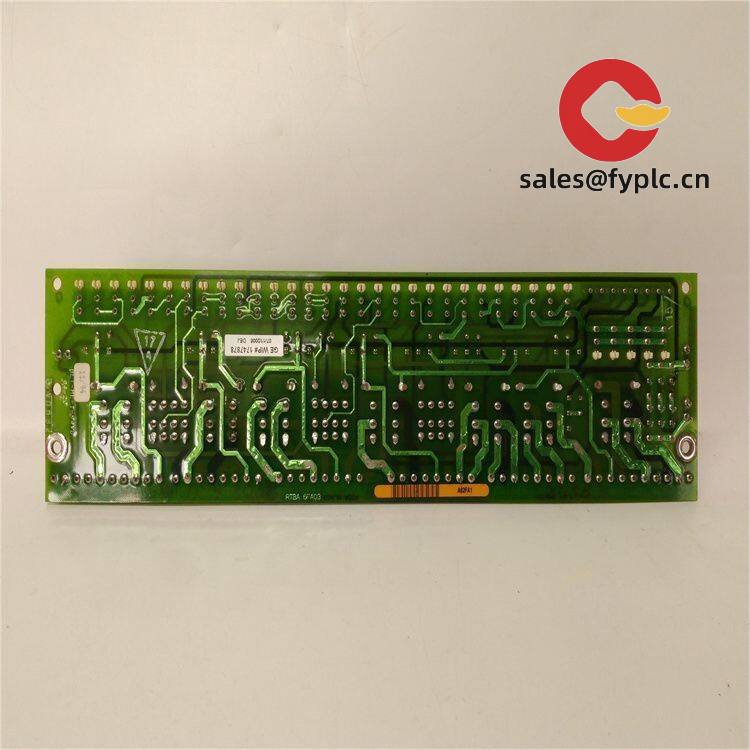

| Installation Method | Panel/backplate mounting inside GE DS200-series cabinets; fixed with standoffs/screws |

| Form Factor | Standard DS200 terminal board footprint, suitable for 19-inch bay enclosures |

Application Fields

The DS200RTBAG3AEB typically sits between the controller and field devices where robust relay outputs are preferred:

- Gas/steam turbine control (Mark V cabinets): permissives, trip chains, and interlocks

- Excitation systems (EX2000): breaker control, contactor logic, alarm relays

- Large AC/DC drives: motor starters, brake control, run/stop signaling

- Balance-of-plant panels: fans, pumps, and dampers requiring dry-contact actuation

- Process safety interlocks where galvanic separation from logic is beneficial

A maintenance lead told us they swapped a failing relay bank with this board during a short outage, and the cabinet passed functional checks in under an hour—no rewiring, no changes to the I/O map. That seems to be the typical experience when replacing like-for-like DS200 parts.

Advantages & Value

- Drop‑in replacement – Keeps your existing wiring and logic; minimizes commissioning time.

- Reliability – Mechanical relays with proven field life; easy to carry spares for critical circuits.

- Compatibility – Designed for GE DS200 cabinets used across drives, exciters, and turbine controls.

- Cost control – Shorter downtime and straightforward troubleshooting typically reduce service hours.

- Support – We can assist with part matching by serial list/BOM and advise on relay coil voltage variants.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry control cabinet with adequate ventilation; maintain 0–60°C ambient and non‑condensing humidity.

- Mounting – Use the provided standoffs/screw points on the DS200 frame; avoid mechanical stress on terminal blocks.

- Wiring – Use appropriately rated copper conductors; torque terminals to spec; route power and signal wiring separately to reduce noise.

- Safety – De-energize all sources before service; verify isolation; follow plant LOTO and ESD precautions.

- Routine checks – Inspect terminal tightness, relay operation (exercise critical relays), and contact condition during scheduled outages.

- Spares strategy – Keep a ready spare board or spare plug-in relays; it typically cuts mean time to repair for trip circuits.

Quality & Certifications

- Manufactured to industrial control quality standards; GE DS200 series production aligns with ISO 9001 quality systems.

- CE conformance applies at the system level in most GE cabinets; UL/cUL marking typically pertains to the assembled panel.

- RoHS status varies for legacy spares; we can supply new surplus or refurbished units with full functional testing.

- Warranty: 365 days replacement/repair coverage.

Supporting Components (typical)

- Replacement plug-in relays (matching coil voltage/version for G3 builds)

- Multi-pin internal ribbon/harness cables for DS200 backplane connections

- Terminal markers and protective covers for field wiring identification

Reviews

There are no reviews yet.