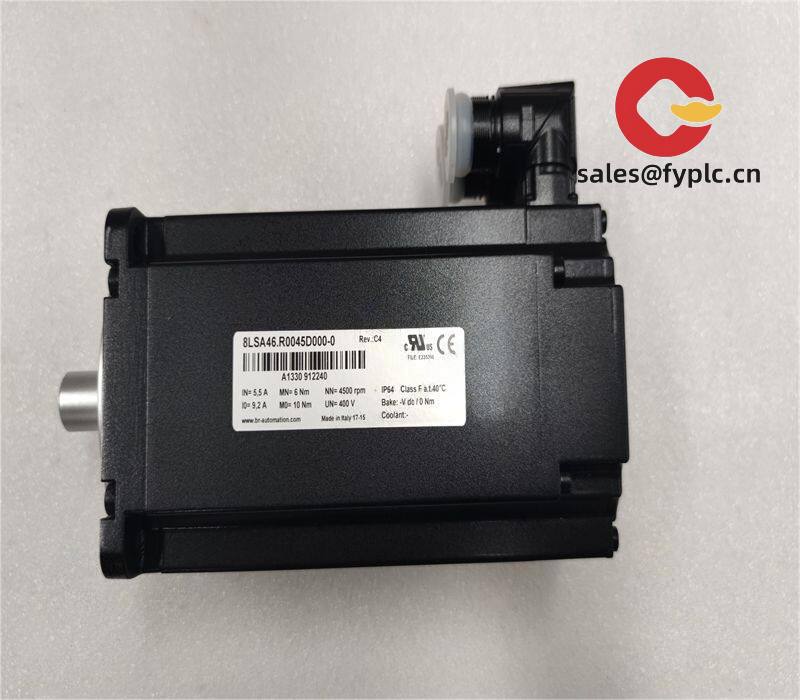

Description

B&R 8MSA8S.E1-P10C High‑Torque Servo Motor – Precise, robust motion for demanding machinery

The B&R 8MSA8S.E1-P10C is part of B&R’s 8MSA series of AC servo motors, geared for applications where high torque density and tight positioning are a daily reality. From my experience, this frame size “8” with the short body “S” is a sweet spot for packaging axes, rotary indexers, and compact gantries that still need punchy acceleration without giving up cabinet or machine space.

Our Order Process & Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- High‑torque, compact frame: The “8S” package typically delivers strong continuous torque in a short body for tight machine layouts.

- Absolute encoder (E1): E1 variant is commonly supplied with a digital absolute feedback (e.g., EnDat 2.2), enabling quick homing‑free startup.

- Smooth low‑speed control: Suits precision tasks like sealing, labeling, or synchronized conveyors where ripple and drift are not welcome.

- Thermal protection built‑in: Integrated motor thermal sensor (PTC/KTY type, depending on variant) to protect against overload.

- Brake option support: Compatible with a 24 VDC holding brake for vertical axes or safety‑critical holds (if configured with brake).

- IP65-ready mechanics: Typically IP65 on the housing with sealed shaft options, useful for dusty or splashing environments.

- Seamless with B&R drives: Designed to pair with B&R ACOPOS / ACOPOSmulti for fast commissioning and reliable diagnostics.

Technical Specifications

| Brand / Model | B&R 8MSA8S.E1-P10C (8MSA series AC servo motor) |

| HS Code | 8501.52 (AC motors, multi‑phase, >750 W and ≤75 kW) |

| Power Requirements | 3‑phase AC via compatible servo drive (B&R ACOPOS/ACOPOSmulti); typically 400 VAC class; 24 VDC for brake (if equipped) |

| Operating Temperature | 0…40 °C ambient (non‑condensing), storage −20…70 °C typical |

| Signal I/O Types | Absolute encoder feedback (E1, digital); motor thermal sensor (PTC/KTY); brake coil (optional) |

| Communication Interfaces | Encoder interface to B&R drive (e.g., EnDat 2.2); no fieldbus on motor |

| Protection | IP65 housing standard; higher at shaft with sealed variant (depending on configuration) |

| Cooling / Duty | Self‑cooled (natural convection); continuous duty S1 |

| Installation Method | Flange mount (IEC B5 style), keyed shaft; standard ground lug |

| Dimensions & Weight | Frame size 8, short body (S). Weight typically in the 9–12 kg range depending on options. |

| Compatibility | B&R ACOPOS / ACOPOSmulti drives; cabling/connector sets as per 8MSA series |

Note: HS classification can vary with rated output and local customs practice; 8501.52 is commonly used for multi‑phase AC servo motors in many cases.

Application Fields

You might notice this model shows up in machines where repeatable torque and compact mounting are priorities:

- Packaging lines: infeed belts, rotary knives, film unwind, and seal bars needing fast changes.

- Printing & converting: tension control, registration rollers, turret winders.

- Electronics assembly: pick‑and‑place axes, screwing units with accurate torque windows.

- Machine tools & robotics: auxiliary axes, indexers, and tool changers where stiffness matters.

- Logistics & labeling: high‑duty applicators, synchronized conveyors.

One thing I appreciate is how quickly these pair with ACOPOS; a customer in food packaging told us their commissioning time dropped because the absolute encoder allowed homing‑free restarts after E‑stops. It seems small, but it saves minutes every shift.

Advantages & Value

- Reliability in tough cycles: Built for continuous S1 duty; thermal sensing guards against misuse.

- Compatibility: Native fit with B&R drives and tools simplifies tuning and diagnostics.

- Space efficiency: High torque in a short body helps keep machines compact without sacrificing dynamics.

- Lifecycle savings: Reduced setup time and fewer encoder/homing routines typically cut downtime.

- Supportable choice: We can help with matching cables, brakes, and drive sizing, which lowers integration risk.

Installation & Maintenance

- Mounting: Use a rigid IEC B5 flange surface; ensure shaft alignment within tolerance to minimize bearing load.

- Wiring: Route power and feedback cables separately; use shielded encoder cables and proper 360° grounding at connectors.

- Environment: Keep within 0…40 °C ambient; allow airflow around the motor body. For washdown areas, select sealed shaft options.

- Brake safety: If a brake is fitted, supply stable 24 VDC; never remove the motor from a vertical axis without mechanically securing the load.

- Checks & care: Periodically inspect connectors, seals, and cable strain relief; clean dust buildup to maintain cooling.

- Drive firmware: While the motor has no firmware, keeping the ACOPOS drive firmware current often improves encoder handling and diagnostics.

- Calibration: No routine calibration is required; verify encoder data and motor parameters after mechanical service.

Quality & Certifications

- CE conformity

- UL Recognized (typical for 8MSA series motors)

- RoHS compliance

- Manufacturing under ISO‑certified quality systems (manufacturer standard)

- Warranty: 365 days (our supply policy)

Reviews

There are no reviews yet.