Description

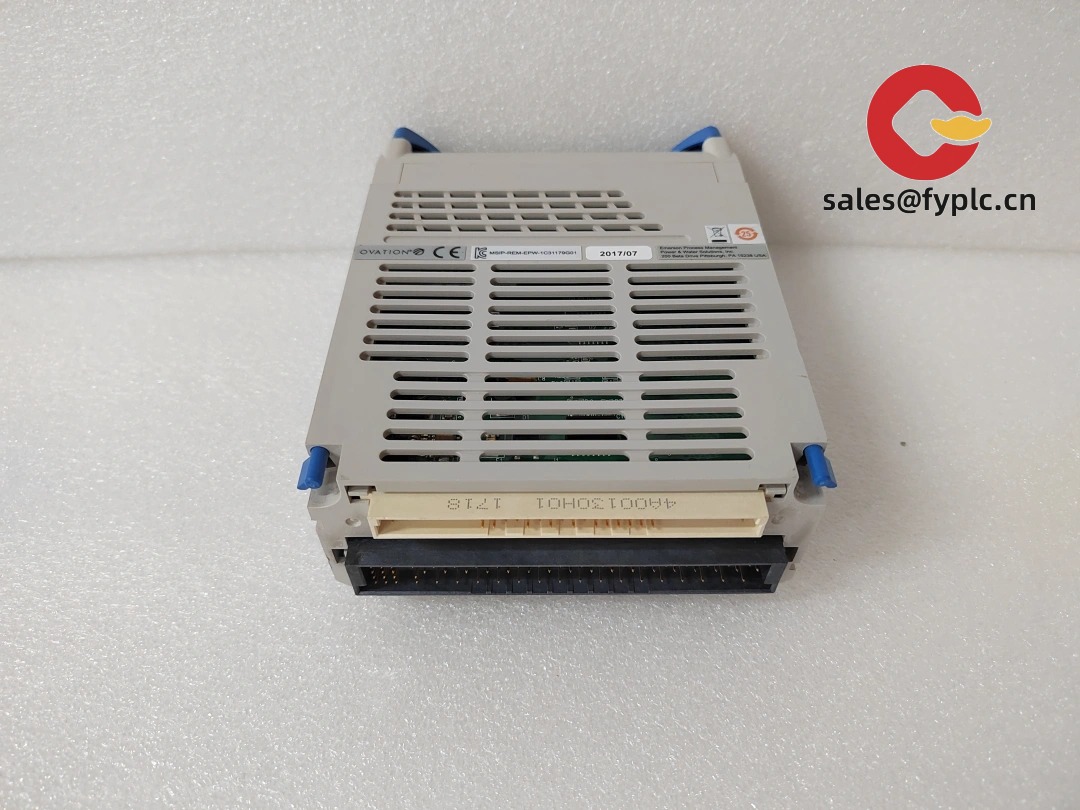

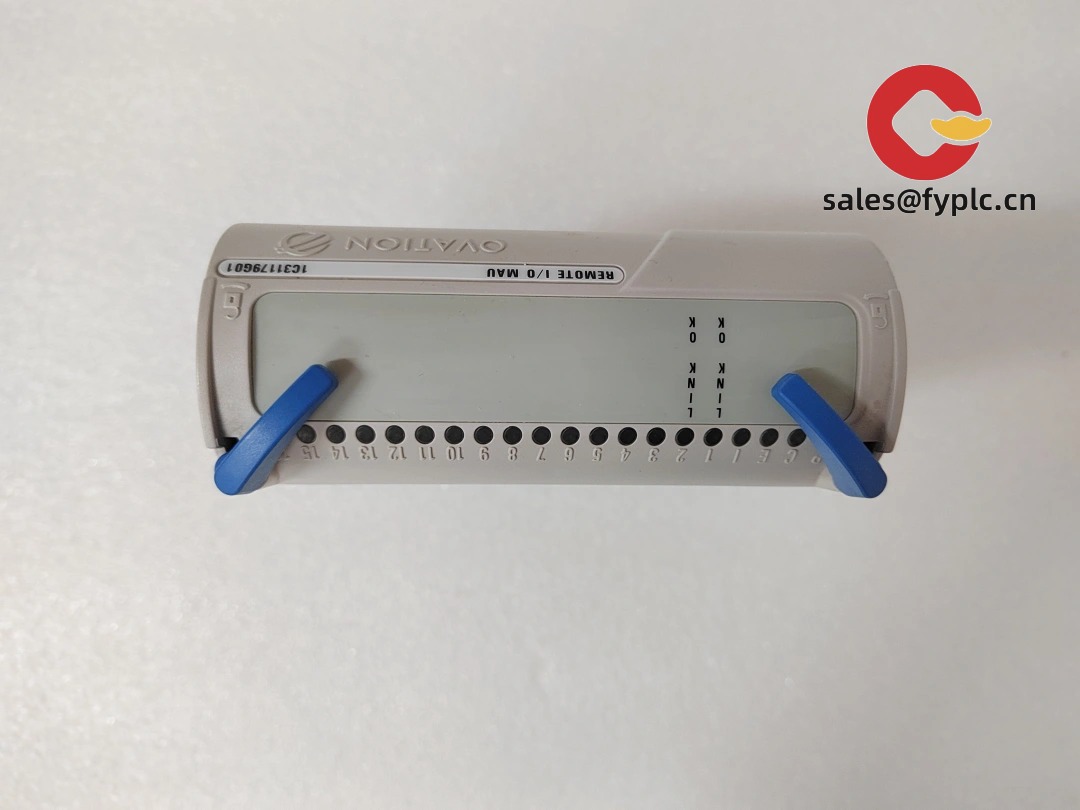

Emerson 1C31179G01 Remote I/O Module – Field I/O expansion for Ovation DCS, built for stable plant operation

The Emerson 1C31179G01 is a Remote I/O module for the Ovation distributed control system. From my experience, it’s typically used to extend mixed signal coverage (DI/DO/AI/AO) closer to the process, reducing marshalling and cabinet wiring. Plants like power generation, water treatment, and midstream facilities choose this module when they want dependable field connectivity and straightforward integration into existing Ovation nodes. You might notice that it prioritizes stable communications and redundant architectures over flashy features—and that’s exactly what most control rooms prefer.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: typically 1 week when in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Ovation system compatibility – Designed for Emerson Ovation DCS, making engineering and maintenance consistent across units.

- Remote expansion of mixed I/O – Supports typical combinations of digital and analog signals via associated Ovation I/O carriers and terminal panels.

- Reliable communications – Built for steady, low-latency data exchange on the Ovation I/O network; redundancy is commonly supported in many deployments.

- Cabinet-friendly footprint – A standard Ovation module form factor that fits established panel layouts and wiring practices.

- Lifecycle-focused – Seems to be favored by plants aiming to maintain long-term spares strategies and backward-compatible upgrades.

- Improved wiring efficiency – Locating I/O closer to equipment typically cuts homeruns and reduces commissioning hours.

Technical Specifications

| Brand / Model | Emerson Ovation / 1C31179G01 |

| Product Type | Remote I/O module (RIO) for Ovation DCS |

| HS Code | 8537.10 (Boards/panels for electric control, ≤1000 V; indicative, final classification may vary by jurisdiction) |

| Power Requirements | Powered via system backplane; nominal 24 VDC typical in many Ovation I/O cabinets |

| Dimensions & Weight | Standard Ovation 1-slot module; typically under 0.5 kg (varies by revision) |

| Operating Temperature | 0 to 60°C typical control cabinet environment (non-condensing) |

| Signal Input/Output Types | Supports mixed DI/DO/AI/AO via associated Ovation I/O carriers and terminal assemblies; channel counts depend on the attached packs/boards |

| Communication Interfaces | Ovation I/O network interface; redundant links commonly available in many system builds (topology depends on project) |

| Installation Method | Mounted in an Ovation I/O chassis/carrier within a control cabinet; field wiring via designated terminal boards |

Note: Specs may vary by hardware revision and site engineering standards. If you share your exact Ovation node configuration, we can verify compatibility down to the carrier and terminal board level.

Application Fields

Plants use the 1C31179G01 when they want dependable remote expansion without reworking the control strategy. Typical deployments include:

- Power generation (boiler/turbine auxiliaries, BOP skids, emissions systems)

- Water & wastewater (pumping stations, clarifiers, chemical dosing)

- Oil & gas midstream (compressor stations, filtration, metering)

- Chemical & petrochemical units (utilities, tanks, packaged equipment)

- Metals, pulp & paper and other continuous processes with distributed field I/O

One maintenance lead told us their main win was “cleaner cabinets and easier loop checks”—moving I/O closer to the skid trimmed days off their commissioning window.

Advantages & Value

- Reliability you can plan around – Stable comms and a proven Ovation ecosystem reduce nuisance faults and callouts.

- Compatibility – Works within Ovation engineering tools and diagnostics, so your team stays in a familiar workflow.

- Cost control – Remote I/O architecture typically lowers wiring, marshalling, and panel real-estate costs.

- Spares strategy – Common form factor simplifies stocking and swap procedures; helps standardize across units.

- Technical support – We can pre-check firmware levels and provide set-up notes tailored to your cabinet layout.

Installation & Maintenance

- Cabinet environment – Install in a clean, ventilated control cabinet; follow typical Ovation panel spacing and airflow guidance.

- Power and grounding – Use stable 24 VDC and a low-impedance ground; separate field returns from control ground where specified.

- Wiring practices – Follow shield termination rules for analog signals; label field terminations to match Ovation point database.

- Redundancy – Where required, configure redundant network paths and document switchover tests during FAT/SAT.

- Routine care – Periodic terminal re-torque, dust removal with dry air, and review of diagnostics in the Ovation toolset.

- Firmware & configuration – Keep firmware at site-approved levels; back up configurations before any changes.

- ESD safety – Handle modules with ESD protection and isolate cabinet power before insertion or removal.

Quality & Certifications

- Certifications: Typically conforms to CE and UL for control equipment; RoHS alignment on many recent revisions

- Quality system: Manufacturer operates under ISO-based quality processes

- Warranty: 365-day warranty from our side; extended coverage and test reports available on request

Related/Supporting Components

If you’re expanding a node, we can also supply compatible Ovation I/O carriers, terminal boards, and associated analog/digital I/O packs, plus panel-rated power supplies and pre-made shielded cable assemblies. Share your I/O list and cabinet photos, and we’ll map the exact parts to your revision level—saves time and avoids mismatches.

Reviews

There are no reviews yet.