Description

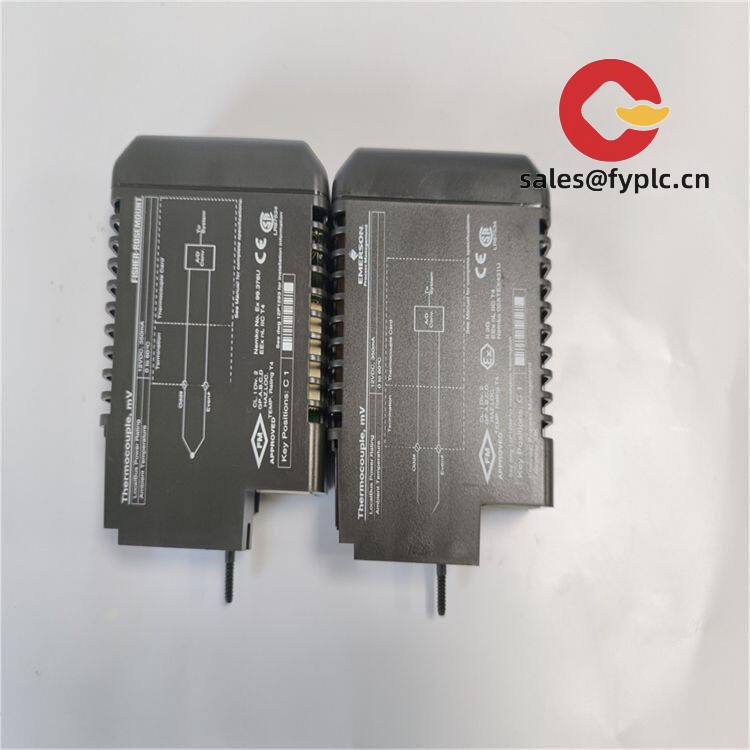

Emerson VE4003S5B1 Standard I/O Termination Block – Clean, dependable field wiring for DeltaV S-series I/O

The Emerson VE4003S5B1 is a standard (non‑fused) I/O termination block designed for DeltaV S‑series I/O. From my experience, it’s the piece that quietly makes panel work simpler: reliable screw/plug terminations on the front, a secure mating interface to the I/O card on the back, and nothing extra to go wrong. You might notice that it’s built for fast swaps during outages, which typically means less downtime and fewer surprises when you’re tracing wires.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Standard (non‑fused) design – A straightforward termination block without onboard fusing or relays; ideal when protection is handled upstream.

- Front‑pluggable, quick service – The block mates directly to the S‑series I/O card, making replacement typically a matter of minutes.

- Secure field terminations – Robust terminals for analog and discrete wiring help reduce loose connections and intermittent faults.

- Keyed interface – Helps prevent mis‑mating with the host I/O card, a small detail that saves rework in many cases.

- HART pass‑through (with HART I/O cards) – When paired with HART‑capable DeltaV cards, device diagnostics can pass through the termination block to the system.

- Panel‑friendly footprint – Compact front profile fits standard cabinet layouts on DIN‑rail mounted I/O carriers.

- Labeling and channel identification – Clear channel marking simplifies commissioning and future maintenance.

Technical Specifications

| Brand / Model | Emerson VE4003S5B1 (Standard I/O Termination Block for DeltaV S‑series) |

|---|---|

| HS Code | 853690 (Electrical apparatus for connections, other) |

| Power Requirements | Passive component; no external power required |

| Signal I/O Types | Compatible with S‑series AI/DI/AO/DO field terminations; supports typical 24 VDC discrete and 4–20 mA analog circuits; HART pass‑through when used with HART I/O cards |

| Communication Interfaces | Back‑plane style mating interface to the S‑series I/O card; front screw/plug terminals for field wiring |

| Installation Method | Front‑pluggable to the DeltaV S‑series I/O card on a DIN‑rail mounted carrier; tool‑less latch mechanism |

| Operating Temperature | Typically follows host I/O card operating range (commonly 0 to 55 °C in control cabinets) |

| Dimensions & Weight | Compact front‑mount TB form factor; lightweight passive module |

Application Fields

The VE4003S5B1 fits control cabinets where DeltaV S‑series I/O is deployed. Typical sites include oil & gas separation and gathering skids, chemical unit operations, power plant balance‑of‑plant panels, water/wastewater lift stations, and pharmaceutical utilities. One thing I appreciate is how it keeps mixed signal cabinets tidy—analog loops, 24 VDC discrete, and HART diagnostics pass right through without extra terminal blocks.

Advantages & Value

- Reliability – Stable terminations reduce nuisance trips and intermittent readings, especially in cabinets that see vibration.

- Compatibility – Designed for DeltaV S‑series I/O cards, so channel mapping and HART passthrough behave as expected.

- Maintenance speed – Removable block design typically shortens outage windows and simplifies loop isolation.

- Cost control – Standard (non‑fused) type avoids paying for protection you already have upstream.

- Lifecycle support – Easy to stock and swap, which in many cases lowers spares carrying cost.

A maintenance lead at a gas processing site told us their team swapped two VE4003S5B1 blocks during a short outage—no rewiring of the card side, and loop checks were done before lunch. That’s the kind of practical benefit that tends to matter day‑to‑day.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry control cabinet with adequate ventilation; keep within the host I/O card temperature rating.

- Mounting – Attach the termination block to the S‑series I/O card on its DIN‑rail carrier; confirm correct keying before latching.

- Wiring – Use properly sized conductors and ferrules where applicable; segregate analog and discrete bundles to minimize noise coupling.

- Safety – De‑energize affected circuits and observe ESD controls before handling; verify loop polarity on analog channels.

- Routine care – Periodically re‑torque terminals per Emerson guidance, inspect for loosened conductors, and clean dust with dry air.

- Documentation – Keep channel labeling up to date; when HART devices are used, note tag/loop mapping in the maintenance log.

Quality & Certifications

- Designed for use within Emerson DeltaV systems; typically conforms to CE and UL requirements for control cabinets

- RoHS compliance is common for this family; exact build certifications can be confirmed on request

- Manufacturer’s warranty support complemented by our 365‑day warranty policy

Reviews

There are no reviews yet.